How long from file submission to first prototypes?

Timeline From File Submission to First Prototypes

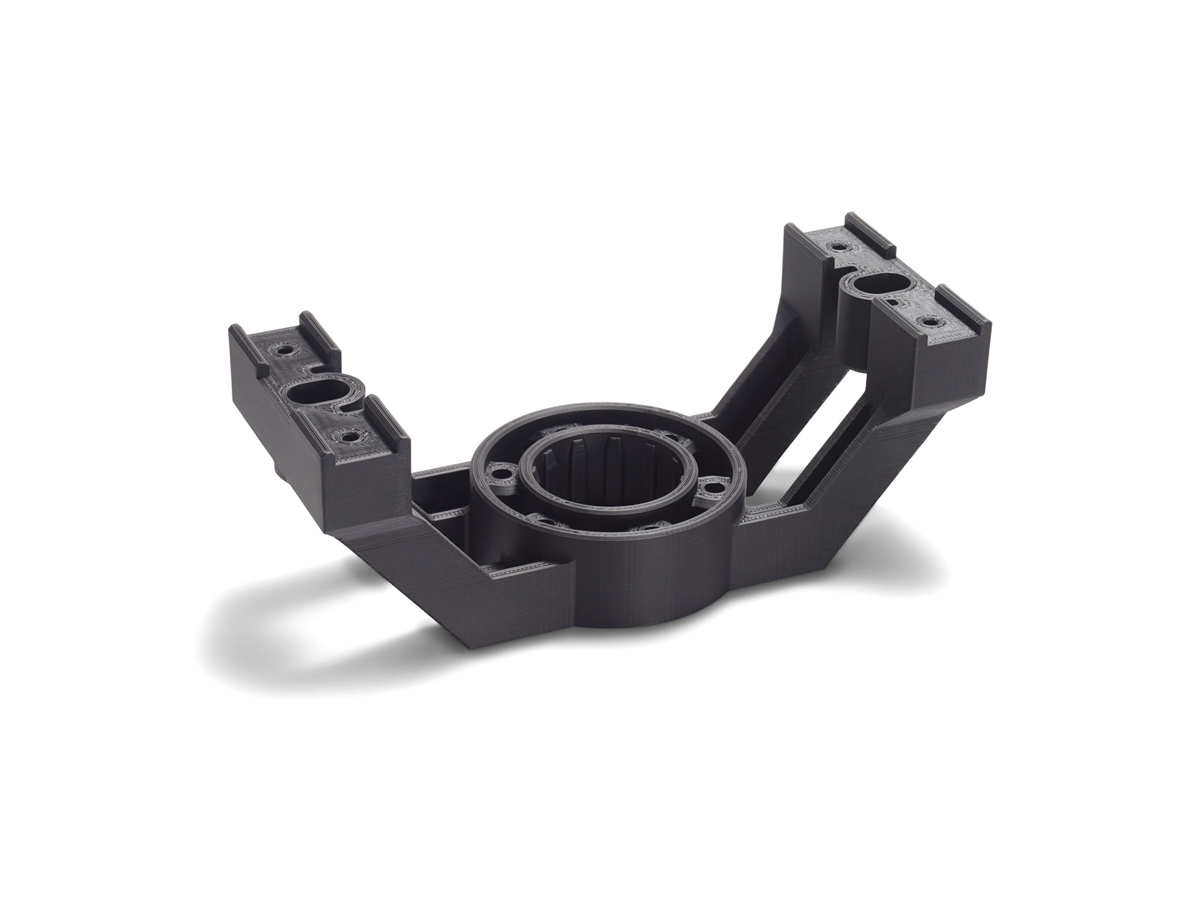

The lead time from receiving customer drawings or 3D models to delivering the first prototypes depends on the part's complexity, the chosen manufacturing method, and the required material performance. At Neway, the workflow is optimized to move from design review to physical samples with minimal delay. Most prototype programs begin with digital DFM analysis, followed by rapid tooling or direct machining. The timeline varies between ultra-fast CNC/3D-printed samples and process-validated prototypes for molding, MIM, or casting.

Typical Prototype Lead Times by Process

Process | Description | Typical Lead Time |

|---|---|---|

Best for metal or plastic parts requiring high precision, functional fit checks, or fast mechanical validation. | 1–3 days for simple parts; 3–7 days for multi-surface or tight-tolerance components | |

Ultra-fast option for form, fit, and initial mechanical evaluation using plastics or metal powders. | 1–3 days depending on geometry and material | |

Ideal for near-production plastic housings or components requiring molded-quality textures and tolerances. | 7–15 days including soft-tool fabrication | |

Used for microstructures or complex metal geometries requiring sintering. Includes mold fabrication and process tuning. | 20–30 days for tooling + 3–5 days for first sintered samples | |

Suited for structural metal parts with thicker walls or internal passages; includes wax tooling and casting trials. | 12–25 days depending on mold complexity |

Factors That Influence Prototype Speed

• **Geometry complexity:** Micro-features, deep pockets, or undercuts extend machining and mold-making time. • **Material type:** High-performance metals such as Inconel 625 or Ti-6Al-4V may require additional programming or heat treatment. • **Surface finish requirements:** Polished, textured, or cosmetic surfaces may add 2–4 days. • **Tolerance targets:** Ultra-tight tolerances require slower cutting speeds or multiple iterations.

What Customers Can Expect

For most projects, Neway provides first workable prototypes within **3–7 days** through machining or 3D printing. For molded or sintered parts that require tooling, customers typically receive their first articles within 2–4 weeks, depending on the complexity of the tool and the process validation. Full engineering communication accompanies each stage to ensure the prototype matches functional intent before entering mass-production tooling.