How does material selection impact the performance of sand-cast products?

Introduction

In sand casting, material selection is one of the most critical factors influencing the mechanical properties, surface quality, and long-term durability of finished components. The chosen alloy determines how well a product performs under stress, heat, or corrosion. Selecting the right metal not only ensures optimal function but also affects post-processing steps such as heat treatment, anodizing, and painting.

Strength and Mechanical Performance

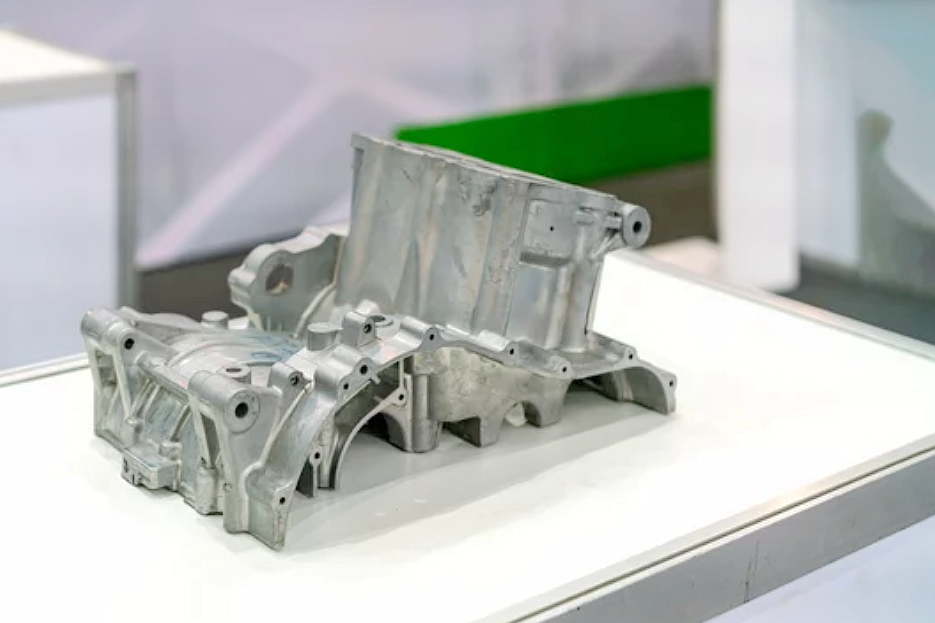

The mechanical strength of a sand-cast product is directly tied to the alloy composition. For example, carbon steel offers superior tensile strength and fatigue resistance, making it ideal for heavy-duty automotive and industrial machinery parts. In contrast, aluminum alloys like A380 or A356 combine sufficient strength with low density, enabling lightweight solutions for e-mobility and aerospace applications. Meanwhile, cast iron excels in vibration damping and stability, ensuring precise performance in engine housings and machine bases.

Corrosion and Thermal Resistance

In environments exposed to moisture, chemicals, or high temperatures, corrosion and oxidation resistance become paramount. Cast stainless steel and nickel-based alloys maintain integrity under harsh conditions, commonly used in energy and telecommunication systems. Aluminum alloys, when combined with anodizing or powder coating, exhibit enhanced corrosion protection and UV resistance—ideal for outdoor and marine applications.

Machinability and Post-Processing Efficiency

The machinability of a material affects the precision and cost of subsequent operations such as CNC machining and surface finishing. Softer metals like aluminum and copper alloys are easier to machine and polish, achieving high-quality finishes with minimal effort. Harder materials, such as tool steels or certain stainless steels, may require grinding or polishing to achieve similar results. Efficient material selection can therefore reduce tooling wear and cycle time, optimizing production efficiency.

Weight and Thermal Conductivity

For applications demanding lightweight yet strong components, materials like magnesium and aluminum alloys are preferred due to their superior strength-to-weight ratios. In contrast, copper alloys deliver exceptional thermal and electrical conductivity, making them ideal for power tools and heat exchange systems. The choice between these metals has a direct impact on energy efficiency and operational reliability.

Cost and Sustainability Considerations

Material cost and recyclability are also major factors. Aluminum and iron alloys are cost-efficient and easily recyclable, reducing environmental impact and production waste. High-performance alloys, such as nickel or titanium, improve functional performance but add expense; therefore, they are typically reserved for aerospace or medical-grade applications where precision outweighs cost.

Conclusion

Material selection governs every aspect of sand-cast product performance—from strength and weight to corrosion resistance and machinability. By aligning alloy properties with functional requirements and post-processing methods, manufacturers achieve optimal reliability and efficiency across industries. The key lies in balancing material capability, cost, and environmental performance.