Precision Manufacturing for Surgical Instruments & Devices

Precision Manufacturing: The Foundation of Modern Surgical Advancements

In today’s rapidly evolving surgical landscape, precision manufacturing capabilities directly determine the performance and reliability of medical devices. As the engineering team at Neway, we understand that the manufacturing quality of surgical instruments is not only about procedural efficiency, but is also closely tied to patient safety. From minimally invasive instruments to orthopedic tools, from endoscopic components to dental devices, every precision part must deliver outstanding performance under the demanding conditions of clinical use.

Key Manufacturing Processes to Meet Stringent Medical Requirements

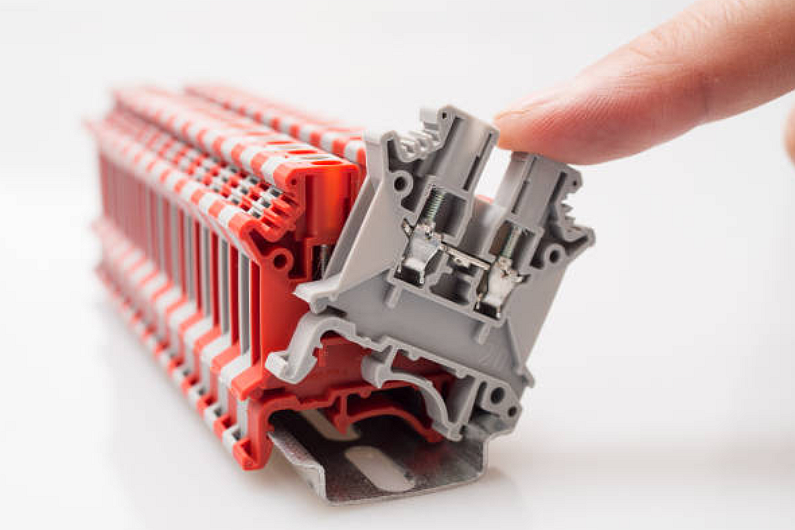

Metal Injection Molding: Mass Production of Complex Micro Instruments

In the field of minimally invasive surgical instrument manufacturing, our metal injection molding services deliver irreplaceable value. This technology is particularly suitable for producing orthopedic tool jaws and endoscopic components with complex internal geometries, achieving levels of design complexity that are difficult to realize through conventional machining while maintaining excellent mechanical properties. We use medical-grade feedstock and strictly controlled debinding and sintering processes to ensure uniform microstructure and superior biocompatibility in every component. This approach not only guarantees product consistency but also provides significant cost advantages for our customers.

Precision Micromachining: Guaranteeing Extreme Accuracy and Sharpness

For instruments such as surgical blades and orthopedic drills, where cutting performance is critical, our CNC machining prototyping services offer an ideal solution. With five-axis machining centers and precision grinding technologies, we can achieve ultra-precise cutting edges with radii as small as 5 microns. At the same time, we utilize advanced laser cutting to process thin-walled tubes and special-shaped parts, ensuring smooth, burr-free edges that meet the highest surface quality standards required for surgical instruments.

Precision Injection Molding and Overmolding

For human-machine interface components of surgical instruments, our plastic injection molding services play a crucial role. Through high-precision molds and stringent process control, we manufacture ergonomic handles with anti-slip textures. For applications that require a combination of rigid and soft materials, we offer specialized overmolding services to seamlessly bond rigid plastics with elastomers, ensuring both operator comfort and robust functional performance.

Surface Finishing Technologies That Enable Safety and Functionality

In medical device manufacturing, surface treatment quality is directly linked to product safety and service life. Our passivation processes significantly enhance the corrosion resistance of stainless steel instruments, ensuring stable performance through repeated sterilization cycles. For endoscopic components and surgical blades that require ultra-smooth surfaces, we employ electropolishing to dramatically reduce surface roughness, minimize the risk of bacterial adhesion, and enhance cleaning and sterilization efficiency.

Critical Material Selection for Medical-Grade Components

Surgical-Grade Metals and Alloys

When it comes to material selection, we prioritize biocompatibility and mechanical performance. Stainless steel remains the primary choice for surgical instruments due to its comprehensive performance advantages. In particular, specially treated martensitic stainless steels offer excellent hardness in conjunction with strong corrosion resistance. For applications requiring higher strength and reduced weight, we recommend titanium alloys, which offer outstanding biocompatibility and an elastic modulus similar to that of human bone, thereby effectively reducing stress shielding.

High-Performance Medical Polymers and Ceramics

With ongoing advancements in medical device technology, high-performance non-metallic materials are increasingly adopted. PEEK, with its excellent mechanical strength and radiolucency, is an ideal material for trauma fixation devices and surgical tools. For applications requiring superior wear resistance and biocompatibility, our ceramic injection molding services enable the production of complex zirconia and alumina components that perform exceptionally well in dental and orthopedic instruments.

Neway’s Precision Manufacturing Practices in the Medical Device Field

Minimally Invasive and Endoscopic Instruments

In the medical device sector, we provide comprehensive manufacturing solutions for minimally invasive surgical instruments. From the precise transmission mechanisms of laparoscopic forceps to the complex optical components of endoscopes, every part undergoes rigorous quality control. We place particular emphasis on operational accuracy and reliability, ensuring that surgeons receive stable tactile feedback and clear visualization during procedures. By optimizing structural design and material selection, we help our customers develop lighter, more user-friendly surgical instruments.

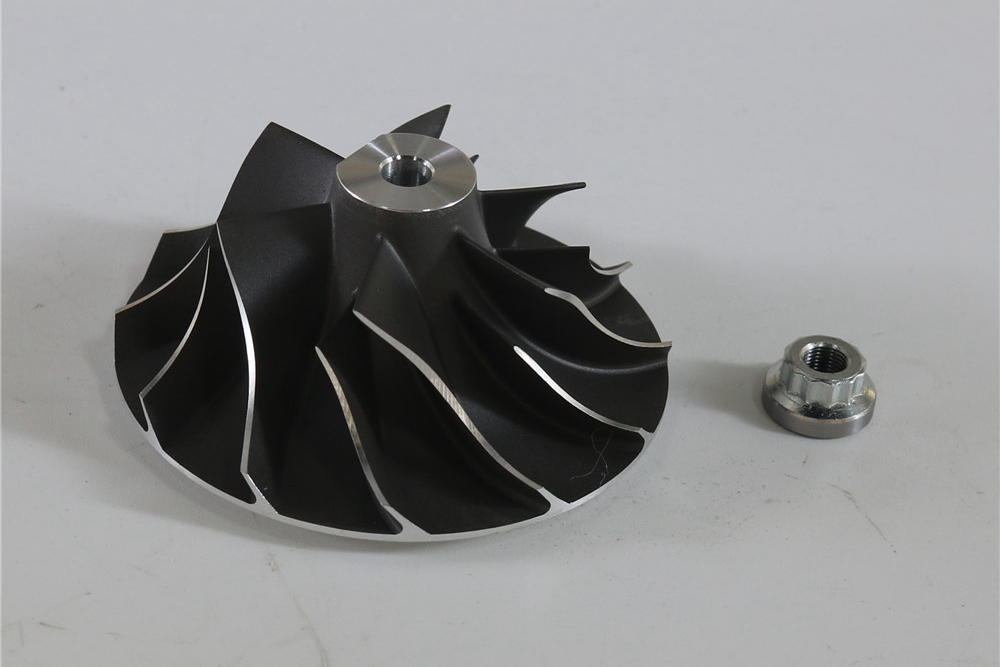

Orthopedic and Dental Surgical Tools

In orthopedic and dental applications, we have extensive expertise in high-speed rotating instruments. From cutting geometry design for orthopedic drills to dynamic balance optimization for dental handpieces, every detail is carefully engineered. We apply specialized surface treatments to enhance wear resistance and rely on precision machining to maintain dimensional stability. These measures significantly extend instrument service life and generate better economic value for healthcare institutions.

Case Study: Collaborating with Customers to Build an Innovative Surgical Platform

One of our recent flagship projects involved developing a new electric bone drill system for an international medical company. By integrating metal injection molding, precision machining, and overmolding processes, we successfully realized a complex internal transmission structure combined with an ergonomic housing design. This project not only demonstrates our capabilities in multi-process integrated manufacturing but also reflects our in-depth understanding of real-world surgical environments.

Choose Neway to Safeguard Your Life-Saving Products

At Neway, we always prioritize quality and safety. Our quality management system strictly adheres to medical device industry standards, with comprehensive controls implemented at every stage, from sourcing raw materials to final product delivery. Our engineering team not only brings strong technical expertise but also a clear understanding of regulatory requirements. Through close collaboration with our customers, we ensure that every product meets the most demanding technical and compliance standards.

Conclusion: Craftsmanship That Honors the Trust of Life

Precision manufacturing for medical devices is a highly demanding undertaking that requires not only advanced technology but also a profound respect for life. With its professional capabilities and rigorous mindset, Neway has established itself as a trusted partner for numerous leading medical companies. We believe that through continuous technological innovation and quality improvement, we can make even greater contributions to the development of the global healthcare industry.

FAQ

What materials and surface treatments suit steam-sterilized surgical instruments?

Can MIM medical parts match the mechanical properties of machined components?

How to ensure micro-machined surgical blades achieve sharpness and consistency?

How does Neway meet ISO 13485 and other medical device quality regulations?

How to choose the best manufacturing process for prototype cost, speed, and validation?