Precision LED & Optical Component Manufacturing Solutions

In modern optoelectronics, the manufacturing quality of precision optical components directly determines the performance of LED lighting, display devices, and optical communication systems. As the engineering team at Neway, we understand that the precision of every optical component influences final luminous efficiency, uniformity, and overall system reliability. From commercial lighting and automotive headlamps to display backlighting and optical communication modules, we are committed to delivering high-end precision manufacturing solutions for our customers.

Key Manufacturing Processes for LED and Optical Components

LED Package Structure and Thermal Management

In LED component manufacturing, thermal performance has a direct impact on service life and lumen stability. Our metal injection molding services are utilized to produce precision LED brackets and substrates, enabling the creation of complex geometries and achieving tight dimensional tolerances to ensure perfect alignment between the chip and its thermal path. For high-power LED applications, we use aluminum die casting to manufacture high-efficiency heat sinks. By optimizing fin geometry and surface treatments, we minimize thermal resistance. Our thermal management solutions keep LED junction temperatures within safe operating ranges, significantly extending device lifetime.

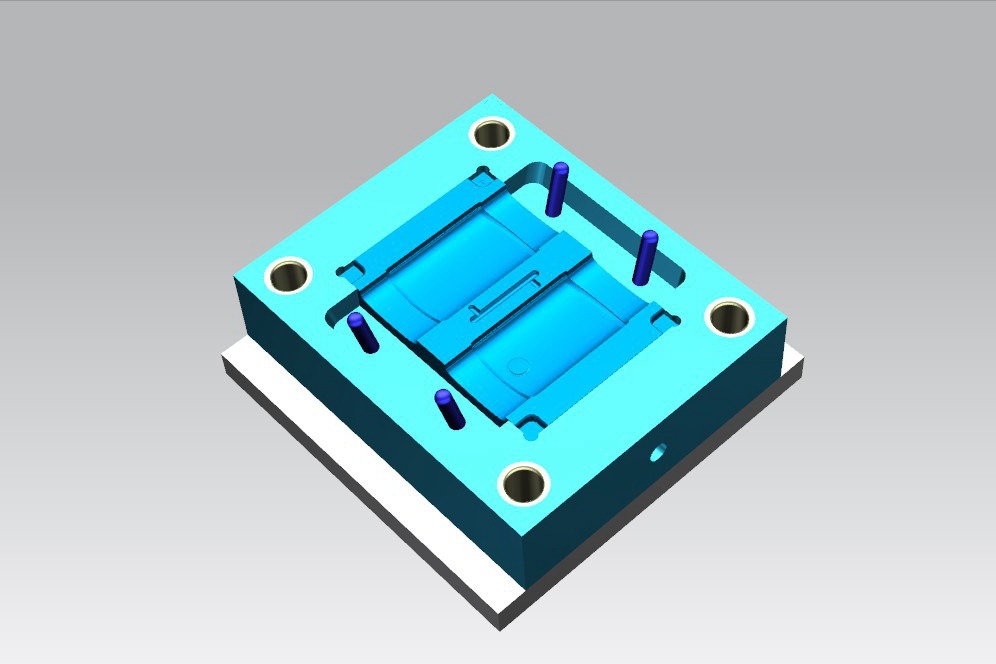

Precision Processing of Optical Lenses and Reflectors

The precision of optical elements directly determines beam distribution and light utilization efficiency. Our plastic injection molding services are specifically optimized for optical-grade polymers, enabling the production of lenses with light transmittance above 92%. Through high-precision mold design and strict process control, we achieve mass production of aspheric lenses that effectively reduce spherical aberration and improve beam quality. For higher-spec metal reflectors, we rely on our CNC machining prototyping services. Using five-axis machining and precision polishing, we achieve optical surfaces with reflectivity above 95%.

Integrated Manufacturing of Housings and Structural Components

In optoelectronic product design, our custom parts manufacturing services enable the integration of optical, structural, and thermal functions into a single solution. Our multifunctional housings not only provide mechanical protection and environmental sealing, but also incorporate optical chambers and thermal channels. Using finite element analysis and optical simulation, we optimize every design detail to achieve IP67 protection while ensuring optimal optical performance and heat dissipation. This integrated approach enables customers to significantly reduce part counts, simplify assembly, and enhance overall reliability.

Surface Treatment Technologies to Enhance Optical Performance and Durability

In optical component manufacturing, surface finishing is crucial for enhancing performance. Our polishing technologies achieve surface roughness of Ra ≤ 0.01 μm, effectively reducing scattering losses. Through multi-stage polishing and rigorous cleaning control, we ensure every optical surface reaches mirror-grade quality. For metal thermal components, we apply anodizing to form dense oxide layers that enhance corrosion resistance and increase surface emissivity, thereby improving heat dissipation. We also apply specialized anti-reflective coatings on optical surfaces, reducing reflection losses to below 0.5%.

Key Material Selection for Optical Components

Optical-Grade Polymers and Glass

Material selection has a direct impact on the performance and service life of optical components. We recommend polycarbonate for lenses requiring high impact resistance, as it maintains high transmittance while withstanding mechanical shocks in harsh environments. For high-temperature applications, we utilize silicone rubber for LED encapsulation lenses, as its excellent thermal stability and flexibility ensure reliability under thermal cycling conditions. We pay special attention to UV resistance, using customized stabilizer systems to significantly extend outdoor service life.

High-Reflectivity and High-Thermal-Conductivity Materials

For reflector manufacturing, we select high-purity aluminum and use specialized refining processes to ensure metal cleanliness, providing a solid foundation for high reflectivity. For thermal management in high-power LED systems, our ceramic injection molding services are used to produce aluminum nitride and alumina ceramic substrates. These materials offer excellent thermal conductivity together with reliable electrical insulation. Through precise sintering control, we ensure uniform microstructures and stable thermal expansion coefficients in ceramic substrates.

Applications of Neway Solutions in Optoelectronic Products

General and Specialty Lighting

In the lighting solutions sector, we offer comprehensive optical component solutions for a diverse range of applications. From downlight lenses for commercial lighting and reflectors for high-bay fixtures, to secondary optics for street lighting and projection modules for automotive headlamps, every component is carefully designed and validated. We focus on precise control of light distribution curves, using advanced optical design and precision manufacturing to achieve target beam patterns and uniformity. In specialty lighting, such as UV curing systems and medical lighting devices, we develop dedicated optical components that meet stringent material and durability requirements while delivering stable optical performance.

Display and Backlight Systems

In display technologies, we manufacture precision light guide plates and optical films for LCD backlight systems. Through microstructure design and nano-scale processing, we achieve excellent brightness uniformity and high optical efficiency. In Mini/Micro LED displays, we develop micron-scale lens arrays and reflective structures to precisely control light output for each pixel. Using advanced injection-compression molding techniques, we ensure ultra-low residual stress and superior flatness in large-area light guide plates.

Emerging Optoelectronic Applications

As optoelectronic technologies evolve, we continue to expand into new application areas. In UV LED systems, we develop UV-resistant optical materials and processes to ensure long-term stability under intense ultraviolet exposure. In optical communications, we manufacture precision collimating lenses and coupling structures for high-speed fiber connectors, where form accuracy directly impacts signal transmission quality. We also produce scanning mirrors and optical windows for LiDAR systems that must maintain high optical accuracy while withstanding high-frequency vibration.

Choose Neway to Unlock Exceptional Optical Performance for Your Optoelectronic Products

At Neway, we have established a complete manufacturing ecosystem for optoelectronic components, covering optical design support, precision mold fabrication, injection molding, and surface treatment. Our optical laboratories are equipped with advanced instruments for accurately measuring transmittance, haze, refractive index, and other key parameters. Strict quality control procedures ensure that every optical component meets design specifications. Recognizing the importance of consistency in optoelectronic applications, we implement comprehensive statistical process control to guarantee uniform performance across large-scale production.

Conclusion: Defining the Form and Quality of Light Through Precision Manufacturing

Advances in optoelectronic technology are closely tied to the support of precision manufacturing. Leveraging our expertise in optical design, materials science, and precision engineering, Neway is committed to delivering premium optoelectronic component solutions to customers worldwide. We believe that through continuous technological innovation and rigorous quality control, we can help our customers achieve breakthroughs in optical performance and jointly drive the evolution of optoelectronic technologies.

FAQ

How to control transmittance, haze, and refractive index accuracy in lenses?

How to choose substrates for high-power LEDs balancing heat, insulation, and cost?

What weather-resistant traits must outdoor optical parts have, and how to achieve them?

How does Neway ensure defect-free optical surfaces for high-end lighting needs?

What support does Neway offer from optical simulation to prototype beam validation?