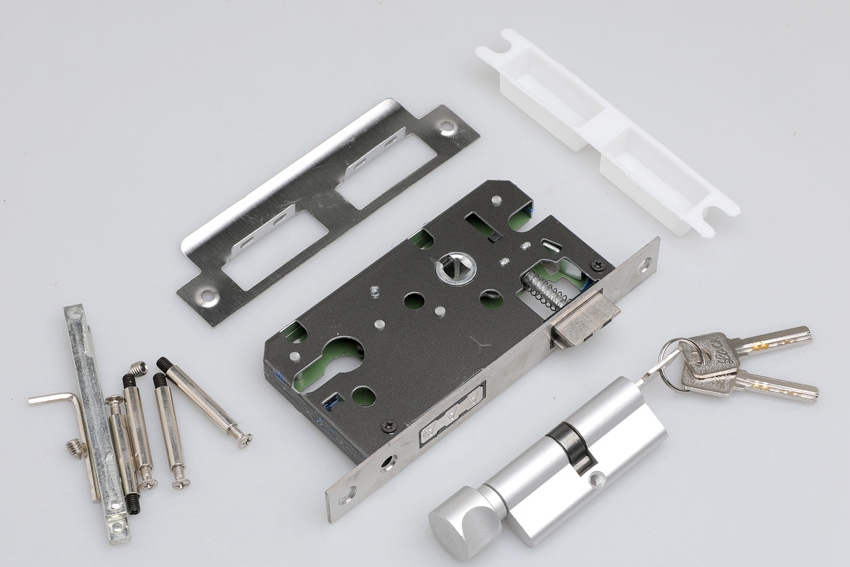

Präzise Leichtbau-Komponentenlösungen für Schließsysteme

Im modernen Schließsystemdesign sind Leichtbau und hohe Präzision zu unumkehrbaren Kerntrends geworden. Von tragbaren Vorhängeschlössern bis hin zu intelligenten Türschlössern verlangt der Markt von Schließprodukten geringeres Gewicht, kleinere Baugröße und höhere Festigkeit. Als Neways Engineering-Team wissen wir, dass exzellentes Leichtbaudesign nicht einfach bedeutet, Material zu reduzieren, sondern durch wissenschaftliche Prozessauswahl, Materialabstimmung und strukturelle Optimierung das optimale Gleichgewicht zwischen Leistung und Gewicht zu erreichen. Präzise Leichtbau-Schlosskomponenten verbessern nicht nur die Nutzererfahrung und die Portabilität des Produkts, sondern erzielen durch Strukturoptimierung auch den doppelten Nutzen aus Materialeinsparung und Leistungssteigerung.

Fortschrittliche Fertigungsprozesse für leichte Präzisionskomponenten

Metallpulverspritzguss (MIM): Der perfekte Prozess für komplexe, leichte Kleinbauteile

Metallpulverspritzguss bietet eine ideale Lösung für das Leichtbaudesign kleiner und komplexer Schlosskomponenten. Metallpulverspritzguss (MIM)-Services ermöglichen die einstufige Formgebung von Präzisionsteilen mit komplexen dreidimensionalen Geometrien, minimieren den Materialeinsatz und erhalten gleichzeitig die strukturelle Festigkeit. Dieses Verfahren eignet sich besonders für die Herstellung von Schlüsselkomponenten wie Schließzylindern, Stiften, Mikro-Zahnrädern und Übertragungselementen. Die Dichte von MIM-Teilen kann mehr als 95% des theoretischen Werts erreichen, mit mechanischen Eigenschaften nahe denen geschmiedeter Teile. Durch MIM können wir mehrere traditionelle Komponenten in einem einzigen Teil integrieren, wodurch die Anzahl der Montageschritte reduziert und das Gesamtgewicht sowie die Baugröße verringert werden.

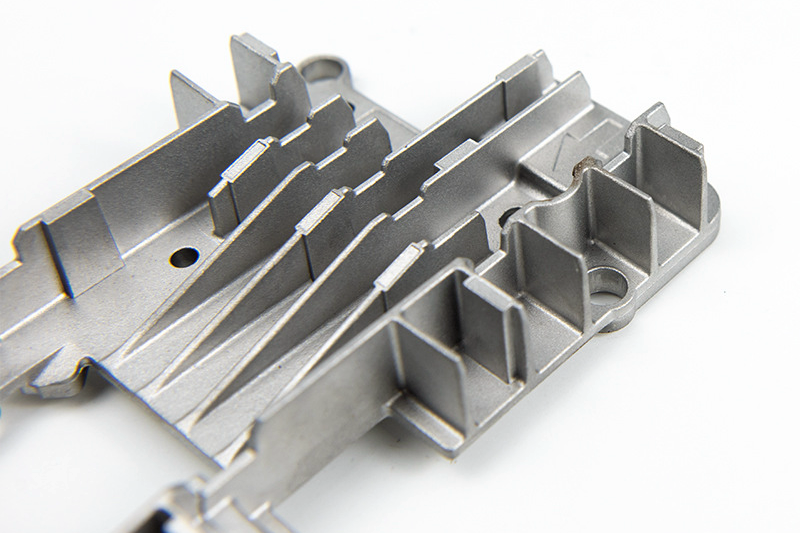

Aluminium-Druckguss: Ideales Gleichgewicht aus hoher Festigkeit und geringem Gewicht

Für größere Komponenten wie Schlossgehäuse, Abdeckungen und Strukturrahmen bietet Aluminium-Druckguss eine hervorragende Leichtbaulösung. Mit einer Dichte von nur etwa einem Drittel von Stahl ermöglichen Aluminiumlegierungen die Herstellung leichter Teile mit gleichmäßiger Wandstärke und optimierten Strukturen durch fortschrittliche Druckgussprozesse und Werkzeugkonstruktion. Hochfließfähige Aluminiumlegierungen füllen komplexe Formen vollständig aus und bilden Rippen, Montagebasen und andere Strukturmerkmale, sodass ausreichende Steifigkeit und Festigkeit bei reduziertem Materialeinsatz gewährleistet sind. Druckgegossene Aluminiumteile verfügen zudem über eine ausgezeichnete Oberflächenqualität und bieten damit ein ideales Substrat für nachfolgende Veredelungen.

Feinguss: Strukturoptimierung zur Gewichtsreduzierung

Wenn Schlosskomponenten spezielle Strukturdesigns benötigen, um maximale Leichtbauleistung zu erzielen, zeigt Feinguss besondere Vorteile. Dieses Verfahren ermöglicht es Konstrukteuren, die Grenzen konventioneller Zerspanung zu überwinden und optimierte Strukturen zu realisieren – darunter Hohlbereiche, komplexe Formen und variable Wandstärken. Mit Feinguss fertigen wir Near-Net-Shape-Teile, die nur minimale Nachbearbeitung erfordern, wodurch Materialabfall minimiert wird, während Bauteilintegrität und Konsistenz erhalten bleiben. Für spezialisierte Schlosskomponenten mit kleineren Losgrößen, aber komplexen Designs, bietet Feinguss einen idealen Leichtbau-Fertigungsweg.

CNC-Bearbeitung: Präzises Formen hochleistungsfähiger Leichtbauwerkstoffe

CNC-Bearbeitung (Prototyping) spielt eine entscheidende Rolle bei der Herstellung leichter Schlosskomponenten. Ob Aluminiumlegierungen, Titanlegierungen oder technische Kunststoffe – CNC-Bearbeitung stellt sicher, dass diese Leichtbauwerkstoffe präzise zu Teilen geformt werden, die den Konstruktionsvorgaben entsprechen. Fünfachs-Bearbeitungszentren ermöglichen hochpräzise Bearbeitung komplexer Oberflächen und sichern eine perfekte Passung aller Komponenten. Für Prototyping und Kleinserien bietet CNC-Bearbeitung unübertroffene Flexibilität und Genauigkeit und liefert eine zuverlässige Basis für die Validierung und Optimierung von Leichtbaukonstruktionen.

Oberflächenbehandlungen zur Verbesserung von Leistung und Haltbarkeit

Leichtbauwerkstoffe benötigen häufig speziellen Oberflächenschutz, um die langfristige Performance zu sichern. Eloxieren ist die gängigste Oberflächenbehandlung für Aluminiumlegierungskomponenten. Durch die Bildung einer harten, verschleißfesten Aluminiumoxidschicht erhöht Eloxieren die Oberflächenhärte und Korrosionsbeständigkeit deutlich – bei minimalem Gewichtszuwachs. Die poröse Struktur der Eloxalschicht ermöglicht zudem vielfältige Farboptionen und erfüllt damit ästhetische Anforderungen von Schlossprodukten. Für Anwendungen, die dickere Schutzschichten erfordern, bietet die Pulverbeschichtung einen gleichmäßigen, langlebigen und optisch ansprechenden Schutzfilm, der Kratzern und chemischer Korrosion wirksam widersteht. Edelstahl- und Titanlegierungskomponenten können zusätzlich durch Passivierung verbessert werden, die ihre natürliche Korrosionsbeständigkeit stärkt und langfristige Zuverlässigkeit in feuchten Umgebungen sicherstellt.

Wichtige Werkstoffauswahl für leichte Schlosskomponenten

Aluminiumlegierungsreihen: Maßstab für Leichtbau, hohe Festigkeit und Zerspanbarkeit

Gegossene Aluminiumlegierungen sind aufgrund ihrer hervorragenden Gesamteigenschaften eine bevorzugte Wahl für leichte Schlosskomponenten. Durch Anpassung der Legierungszusammensetzung und geeignete Wärmebehandlungen können Aluminiumlegierungen ein breites Eigenschaftsspektrum erreichen – von guter Zähigkeit bis hin zu hoher Festigkeit. Häufige Druckguss-Aluminiumlegierungen wie A380 und ADC12 bieten gute Fließfähigkeit und Maßstabilität und eignen sich für dünnwandige und komplexe Teile. Wärmebehandelbare Legierungen wie A356 können durch T6-Behandlung verstärkt werden und liefern höhere mechanische Eigenschaften, um die Anforderungen tragender Strukturkomponenten zu erfüllen.

Titanlegierungen: Die ultimative Wahl für extremes Festigkeits-Gewichts-Verhältnis

In hochwertigen Schlossanwendungen, die maximale Leichtbauperformance anstreben, bieten Titanlegierungen unvergleichliche Vorteile. Bei einer Festigkeit vergleichbar mit hochfesten Stählen und einem Gewicht von nur etwa 60% von Stahl bieten Titanlegierungen zudem hervorragende Korrosionsbeständigkeit und Biokompatibilität. Trotz höherer Kosten sind Titanlegierungen unersetzlich, wenn es um Widerstand gegen extreme Umweltkorrosion und maximale Gewichtsreduktion geht. Sie eignen sich besonders für Premium-Outdoor-Schlösser, marine Schlösser und andere Spezialanwendungen, die sowohl sehr geringes Gewicht als auch hohe Zuverlässigkeit verlangen.

Hochleistungsfähige technische Kunststoffe und Verbundwerkstoffe

Für nicht-kritische, nichttragende Strukturen eröffnen Hochleistungs-Kunststoffe neue Möglichkeiten für signifikante Gewichtsreduzierung. PEEK bietet außergewöhnliche Festigkeit, Steifigkeit und Wärmebeständigkeit und ist damit in bestimmten Komponenten eine ideale Alternative zu Metallen. Nylon (PA), insbesondere glasfaserverstärkte Qualitäten, bietet ein starkes Gleichgewicht zwischen mechanischer Leistung und Kosten und wird häufig in internen Strukturkomponenten von Schlössern eingesetzt. Kunststoffteile ermöglichen zudem die Integration mehrerer Funktionsmerkmale – wie Clips und Filmscharniere – wodurch Produktstrukturen weiter vereinfacht und Gewicht reduziert werden.

Zinklegierungen: Wahl für hohe Dichte und Miniaturisierungsanforderungen

Obwohl Zinklegierungen eine relativ hohe Dichte aufweisen, machen ihre hervorragende Gießbarkeit und mechanischen Eigenschaften sie weiterhin wertvoll in bestimmten leichtbauorientierten Designs. Für kleine, hochfeste Komponenten können Zinklegierungen die Funktionsanforderungen durch kompaktes Design erfüllen und unnötige Überdimensionierung vermeiden, die zu zusätzlichem Gewicht führt. Zinklegierungsteile besitzen außerdem eine ausgezeichnete Oberflächenqualität und können mit verschiedenen galvanischen Verfahren veredelt werden, wodurch sowohl Ästhetik als auch Schutz gewährleistet sind.

Anwendungen und Vorteile leichter Präzisionskomponenten in Schließsystemen

Innovation bei tragbaren und Outdoor-Schlössern

Leichtbau verbessert die Nutzererfahrung tragbarer Schlösser direkt. Unsere Lösungen für Schließsysteme konzentrieren sich auf optimierte Designs für Produkte wie Vorhängeschlösser, Fahrradschlösser und Reiseschlösser. Durch die Auswahl geeigneter Werkstoffe und die Auslegung einer robusten Struktur reduzieren wir das Produktgewicht deutlich, während die Sicherheitsleistung erhalten bleibt. Beispielsweise kann der Ersatz traditioneller Stahlgehäuse durch Aluminiumlegierungen das Gewicht um mehr als 60% reduzieren, bei vergleichbarer Aufbruch- und Aufhebelbeständigkeit – und damit die Portabilität und Marktattraktivität erheblich steigern.

Strukturoptimierung für Smart- und elektronische Schlösser

Mit der zunehmenden Verbreitung von Smart Locks wird das interne Platzmanagement immer wichtiger. Leichte Komponenten reduzieren nicht nur das Gesamtgewicht, sondern schaffen auch wertvollen Raum für Batterien, Motoren und Elektronikmodule. Durch den Einsatz von MIM für kleine, hochfeste Übertragungsteile und Aluminium-Druckguss für Strukturrahmen ermöglichen wir unseren Kunden kompaktere Produktlayouts, längere Batterielaufzeiten sowie gleichbleibende strukturelle Integrität und Sicherheit. Leichtbau reduziert zudem die Trägheit bewegter Teile und ermöglicht schnelleres und reaktionsfreudigeres Verriegeln und Entriegeln.

Hochleistungsfähige, bewegte Schlüsselkomponenten

Das Bediengefühl und die Zuverlässigkeit von Schlössern hängen wesentlich von der Leistung bewegter Komponenten ab. Leichte Riegel, Hebel und Kinematik-/Gestänge-Mechanismen reduzieren die Betätigungskraft, erhöhen die Reaktionsgeschwindigkeit und verringern den Verschleiß. Durch präzise Simulationen und physische Validierung stellen wir sicher, dass jede bewegte Komponente bei reduziertem Gewicht ausreichende Festigkeit und Haltbarkeit beibehält. Optimierte Massenverteilung und Trägheitseigenschaften tragen zudem dazu bei, Betriebsgeräusche zu reduzieren und die wahrgenommene Produktqualität weiter zu erhöhen.

Vier Kernprinzipien für das Design leichter Präzisions-Schlosskomponenten

Erfolgreiches Leichtbaudesign erfordert einen systematischen Engineering-Ansatz. Die Topologieoptimierung nutzt Algorithmen, um Material innerhalb eines definierten Designraums so zu verteilen, dass Strukturen leicht und gleichzeitig mechanisch effizient sind. Eine gleichmäßige Wandstärkenkontrolle stellt einen konsistenten Materialfluss während der Fertigung sicher und hilft, Defekte zu vermeiden. Die korrekte Abstimmung von Werkstoffen und Prozessen muss Produktionsvolumen, Leistungsanforderungen und Kosten berücksichtigen, um die optimale Lösung zu finden. Durch Finite-Elemente-Analyse, Prototypentests und reale Validierung stellen wir sicher, dass Leichtbau nicht auf Kosten von Festigkeit oder Haltbarkeit geht – und erreichen so das Ziel „Gewichtsreduzierung ohne Qualitätskompromisse“.

Fazit: Präziser Leichtbau eröffnet eine neue Ära der Schlossperformance

Leichtbau und Präzision sind nicht nur technologische Trends, sondern zentrale Strategien, mit denen die Schlossindustrie vielfältige Marktanforderungen adressiert. Von Werkstoffwissenschaft und Fertigungsprozessen über Strukturdesign bis hin zur Oberflächen-Engineering tragen Innovationen in jeder Phase zur Leistungssteigerung von Schlössern bei. Mit tiefem Know-how in der Multi-Material-Formgebung und umfangreicher branchenübergreifender Erfahrung bietet Neway umfassende Leichtbaulösungen – von der Konzeptentwicklung bis zur Serienproduktion – für Schlosshersteller. Wir arbeiten eng mit unseren Kunden zusammen, um durch ingenieurtechnische Innovation leichtere, kompaktere und stärkere Schlossprodukte zu entwickeln, die eine herausragende Nutzererfahrung bieten.

FAQ

Welche Leichtbauwerkstoffe bieten eine hohe Aufhebel- und Schlagfestigkeit?

Welche Oberflächenbehandlungen schützen Outdoor-Schlösser, ohne viel Gewicht hinzuzufügen?

Welche Vorteile bietet MIM gegenüber Feinguss bei komplexen Leichtbauteilen?

Wie entwirft man Schlösser, die Gewichtsreduzierung mit Festigkeit und Haltbarkeit ausbalancieren?