Why Does the Metal Injection Molding Process Have High Material and Cost Efficiency?

Metal Injection Molding (MIM) has revolutionized the manufacturing of complex, high-performance parts by offering unparalleled efficiency in both material usage and overall costs. This process combines the versatility of plastic injection molding with the strength of powdered metallurgy, making it a popular choice for various industries, including automotive, medical devices, aerospace, consumer electronics, and others. This article examines why MIM offers substantial material and cost efficiencies compared to traditional manufacturing techniques, such as investment casting.

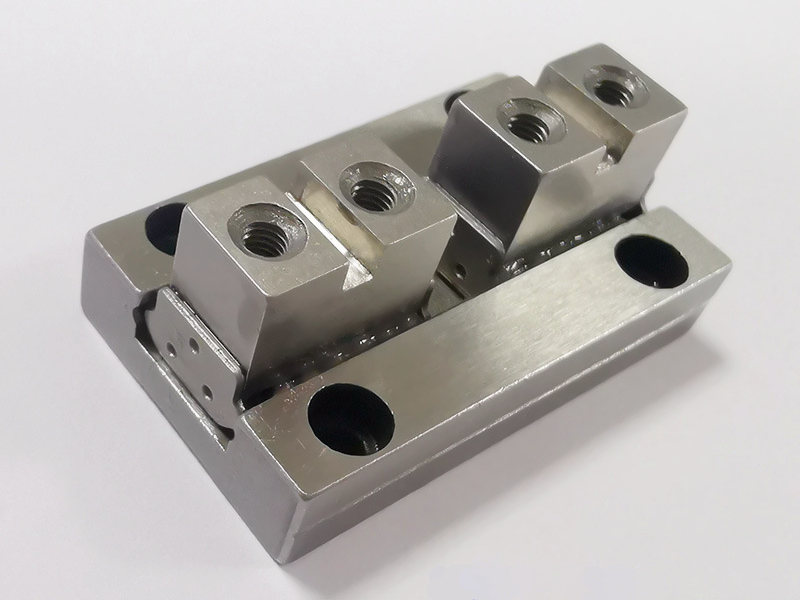

What is Metal Injection Molding?

Metal Injection Molding is an advanced manufacturing technique that combines the flexibility of injection molding with the strength and durability of metal components. It uses fine metal powders mixed with polymer binders to create a feedstock. This mixture is injected into precision molds to create intricate components. After molding, parts undergo a debinding process to remove binders, followed by sintering, which densifies the parts into robust, high-quality final products. This approach significantly enhances the component’s strength compared to traditional methods such as die casting.

How Does Metal Injection Molding Work?

The MIM process involves four main stages:

Feedstock Preparation

High-quality metal powders are carefully blended with polymeric binders to form a homogeneous feedstock. Achieving the optimal balance between powder and binder ensures consistent injection properties and reliable performance of the final part. Effective feedstock preparation has a significant impact on the overall quality and efficiency of the MIM process.

Injection Molding

The feedstock is heated and injected into high-pressure precision molds, forming a "green" part. This injection step enables the efficient and accurate production of complex shapes, closely resembling the capabilities of ceramic injection molding. The precision of mold design directly contributes to reduced material waste and enhanced production efficiency.

Debinding

After injection molding, the polymeric binder is systematically removed in a controlled process known as debinding, leaving a porous metal part, commonly referred to as the "brown part." The debinding step can be executed through solvent extraction or thermal decomposition, preparing the component for final sintering.

Sintering

During sintering, the brown part undergoes heating at high temperatures in a controlled atmosphere, which densifies the component and significantly improves mechanical properties, dimensional accuracy, and durability. The efficiency of sintering contributes substantially to the overall cost-effectiveness and high-quality output of the MIM process.

Material Efficiency in Metal Injection Molding

Near-Net Shape Manufacturing

Metal Injection Molding excels in near-net shape production, significantly reducing material waste compared to subtractive manufacturing methods, such as traditional CNC machining. MIM’s precision molding capability minimizes excess material usage, promoting sustainable manufacturing practices.

Recycling and Reusability

The MIM process efficiently recycles unused materials, such as feedstock remnants and sprues. These materials are reprocessed and reintroduced into production cycles, further enhancing material utilization and reducing waste.

High-Value Material Efficiency

Due to its precision and minimal waste generation, MIM is particularly beneficial when handling high-value materials such as superalloys and precious metals. Optimal material management helps significantly reduce production costs associated with expensive raw materials.

Cost Efficiency Factors of MIM

Mass Production Benefits

MIM's strength lies in mass production scenarios, significantly reducing the cost per component as production scales up. Unlike processes such as precision casting, the fixed costs associated with tooling become negligible at higher volumes, resulting in a dramatic increase in cost efficiency.

Component Consolidation

Metal Injection Molding can combine multiple parts into a single component. This ability greatly reduces assembly costs, simplifies manufacturing processes, and enhances reliability by minimizing potential points of failure.

Reduced Secondary Operations

Due to the high accuracy and smooth finishes achievable through MIM, fewer secondary operations, such as machining and finishing, are required. This translates directly to lower overall production costs and faster turnaround times than processes that typically require extensive post-processing, such as traditional machining or sheet metal stamping.

Conclusion

Metal Injection Molding offers manufacturers an ideal balance between material efficiency and cost-effectiveness, especially when producing intricate and complex parts at high volumes. Its ability to reduce waste, recycle materials, and minimize secondary processes positions MIM as a compelling solution for modern manufacturing demands. Explore more about Neway’s MIM services today to revolutionize your production capabilities.