Mastering MIM Mold Design: 12 Key Considerations

Mold Design Considerations You Need To Know

Metal Injection Molding (MIM) mold design is a crucial aspect of the MIM process, as it directly impacts the quality, consistency, and efficiency of producing complex metal parts.

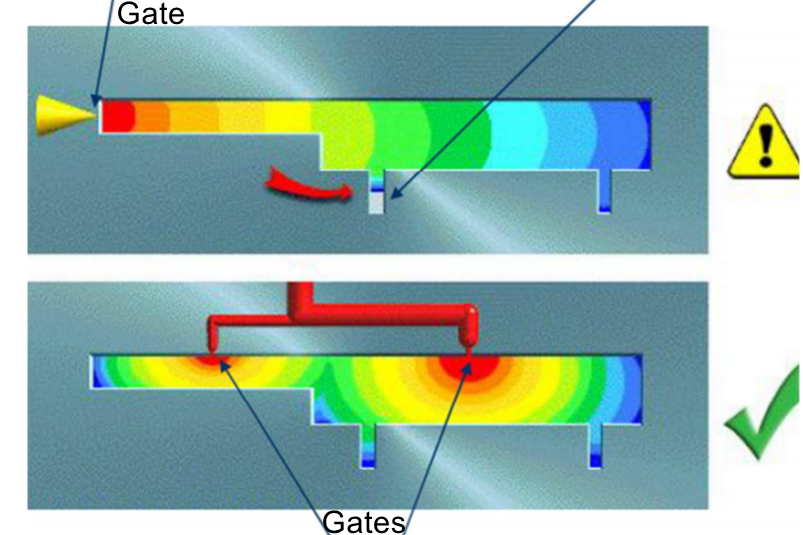

Material Flow and Gating

Optimizing material flow and gating in Metal Injection Molding (MIM) mold design offers significant advantages in achieving high-quality, consistent parts. Properly designed gating systems ensure uniform material distribution within the mold cavity, resulting in parts with consistent dimensions and reduced defects. This uniform filling minimizes common issues like voids, porosity, and sink marks, improving overall part quality. Additionally, efficient gating design allows for optimized cooling during molding, reducing the risk of warping and distortion while ensuring even solidification. It enhances part quality and reduces cycle times, increasing production efficiency and cost-effectiveness.

On the other hand, neglecting proper gating design in MIM mold construction can lead to various defects and challenges. These include gate marks on the part's surface, resulting from inadequate gating, which may require post-processing to remove. Insufficient gating can cause jetting, creating turbulence and defects like voids and poor surface finishes. Flow lines, visible streaks or lines on the part's surface, may also develop due to suboptimal gating design, affecting the part's aesthetics. Moreover, inefficient gating can lead to incomplete mold cavity filling, resulting in short shots and increased scrap rates, adding to production costs.

MIM Part Geometry

Considering part geometry in Metal Injection Molding (MIM) mold design offers a range of benefits. One of the most significant advantages is the ability to produce highly complex and intricate parts that would be challenging or impossible to manufacture using traditional methods. MIM allows for creating parts with thin walls (Min 0.4 mm), fine details, undercuts, and complex internal features. This design flexibility enables engineers to optimize the functionality of components, reduce the need for assembly, and achieve lightweight structures.

Defects associated with part geometry in MIM mold design can arise if design considerations need to be adequately addressed. One common defect is warping or distortion of the part, particularly in areas with varying wall thicknesses. It can occur during the cooling phase of the molding process if heat dissipates unevenly.

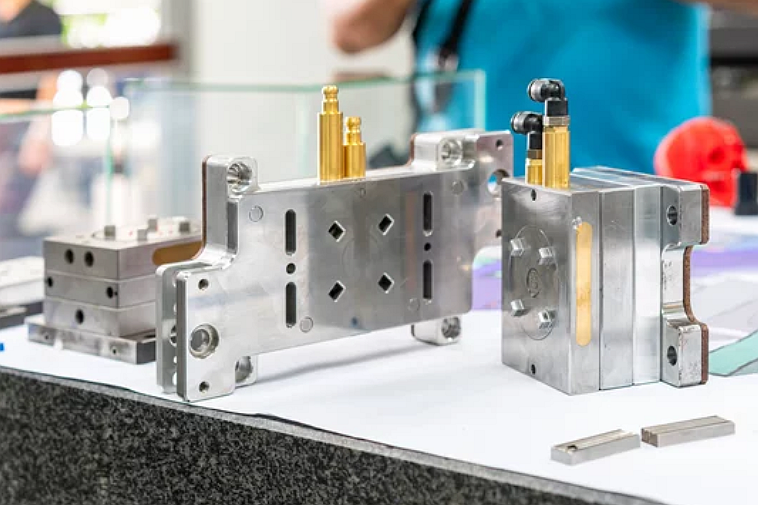

Mold Material and Tooling

One of the primary benefits is the ability to select mold materials that can withstand the high temperatures and pressures involved in the MIM process. High-quality tool steels, such as H13 or P20, offer excellent durability, wear resistance, and heat resistance, ensuring the mold can endure the rigors of repeated molding cycles without deformation or damage. Additionally, the choice of mold material can impact the surface finish of the molded parts, with polished and precision-crafted molds contributing to smoother part surfaces.

On the downside, inadequate consideration of mold material and tooling can lead to defects and challenges in MIM production. For instance, using suboptimal mold materials can result in rapid tool wear, leading to increased maintenance and replacement costs. Mold materials must also be chosen to match the material being molded, as different materials can react differently with the mold surface. The MIM process is suitable for mass production to achieve higher cost performance. Poor mold materials will gradually cause MIM parts to become inconsistent during production.

Runner System

A well-designed runner system can contribute to efficient material distribution, reducing waste and ensuring uniform filling of the mold cavity.

Designing and implementing a runner system can add to tooling costs and complexity. While efficient in some cases, cold runners generate material waste that may need to be recycled or discarded, impacting overall material costs. While reducing waste, hot runner systems require more intricate mold designs and temperature control systems, increasing initial tooling expenses.

Venting

In MIM, where high-precision components are the norm, imperfections caused by inadequate venting can result in defects such as gas porosity, compromising the part's structural integrity. Neway's expert engineers understand the significance of proper venting and leverage their extensive experience to design molds with strategically placed vents tailored to the specific geometry of the component. They ensure that venting channels are appropriately sized to allow the efficient escape of gases, contributing to a flawless final product.

Secondly, Neway's venting approach concerns technical excellence and a commitment to sustainability. They understand that efficient venting minimizes defects and reduces material waste. It aligns with their dedication to environmentally responsible manufacturing. By optimizing venting, Neway enhances production efficiency and reduces the need for rework or scrap, benefiting both the client and the environment. In conclusion, regarding MIM mold design, Neway's expertise in venting is a testament to their commitment to precision, quality, and sustainability.

Shrinkage and Tolerances

Shrinkage and tolerances are pivotal factors that Neway meticulously considers during Metal Injection Molding (MIM) mold design. These aspects are indispensable in achieving the high-precision components that Neway is renowned for.

Firstly, understanding and accounting for material shrinkage is imperative. During the MIM process, the feedstock material transforms from its initial molded state to the final sintered form. This transformation involves shrinkage, which varies depending on the material used. Neglecting this shrinkage factor into the mold design can result in parts not meeting the desired dimensional specifications. Neway's engineers are well-versed in the shrinkage characteristics of various MIM materials and use this knowledge to design molds with compensatory features, ensuring that the final sintered parts meet the precise tolerances required by clients.

Injection Pressure and Speed

Firstly, injection pressure plays a pivotal role in ensuring the complete filling of the mold cavity with MIM feedstock material. Neway's engineers know that insufficient injection pressure can lead to incomplete filling, resulting in voids, sink marks, or incomplete parts. Conversely, excessive pressure can cause overpacking, damage the mold, create warping, or introduce unwanted stresses into the final component.

Neway's approach is to strike the perfect balance by analyzing material properties and mold geometry to determine the ideal injection pressure that guarantees complete mold filling while avoiding negative repercussions.

Secondly, injection speed is another crucial factor in MIM mold design. The rate at which the feedstock material is injected into the mold cavity impacts the final part's integrity, surface finish, and dimensional accuracy. For high-precision components, such as those used in medical or aerospace applications, Neway's meticulous control over injection speed ensures minimal shear forces and material degradation, resulting in parts that meet the most stringent quality standards.

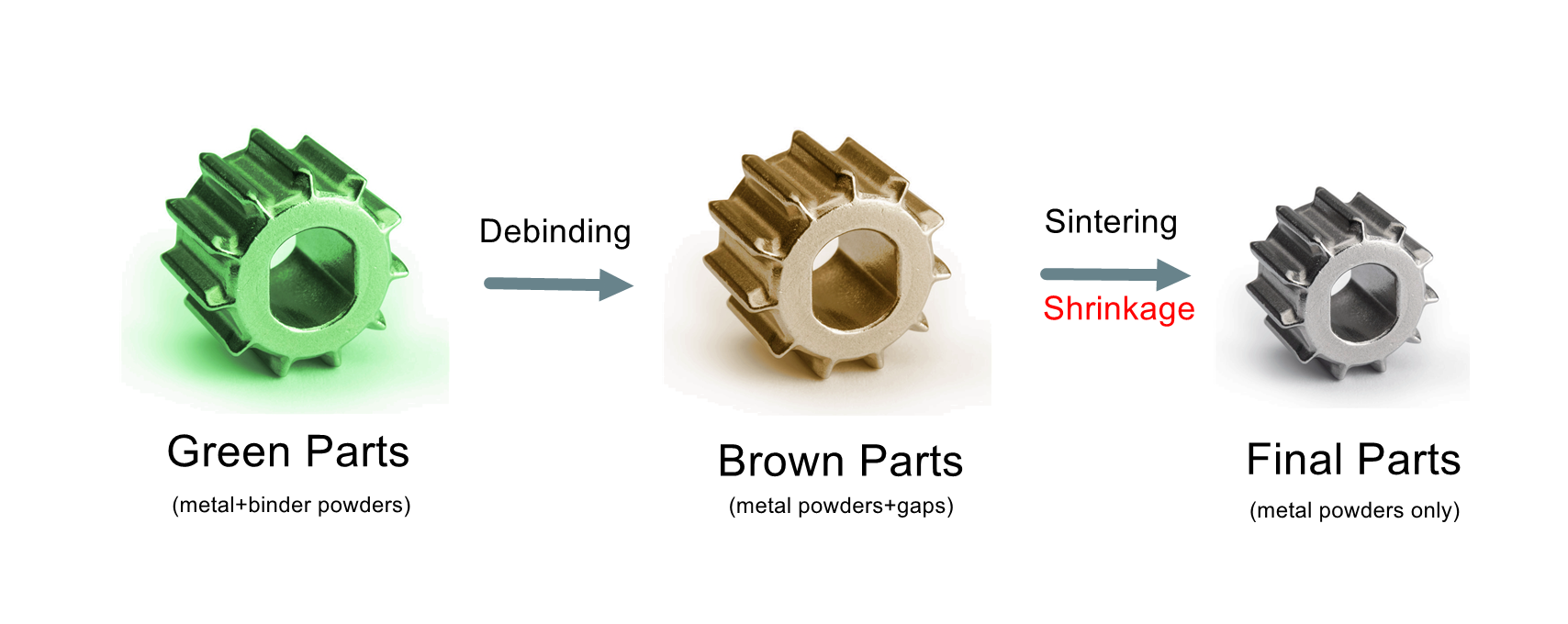

Debinding and Sintering

Debinding and sintering are integral stages in the Metal Injection Molding (MIM) process. Neway places significant emphasis on these phases during mold design to ensure the successful production of high-precision components.

First, debinding is a critical step in MIM, removing the binder material from the green parts. Neway recognizes that improper debinding can lead to residual binder trapped within the part, resulting in defects and compromised mechanical properties. Our meticulous approach to mold design considers the component's geometry and strategically incorporates features like vents and channels that facilitate the efficient removal of binder material during the debinding process. This attention to detail ensures that the final sintered parts are free from residual binders, guaranteeing the desired mechanical properties and dimensional accuracy.

Secondly, sintering is the stage where the debond parts are heated to fuse the metal particles, resulting in a solid, dense component. In our mold design process, we consider the materials' thermal characteristics and design molds that allow consistent and uniform heating throughout the part. This approach guarantees that the final sintered components meet the exacting standards required for applications in industries like aerospace, automotive, and healthcare.

Ejection Mechanism Design

Designing an effective ejection mechanism is crucial to Neway's Metal Injection Molding (MIM) mold design process. Firstly, the selection and placement of ejector pins are paramount. We analyze the component's geometry and identify areas where ejector pins can be strategically positioned. It involves considering part complexity and ensuring that pins are placed in a way that allows for even and controlled ejection. Neway also pays close attention to the size and number of ejector pins, ensuring sufficient force to eject the part without causing damage. Moreover, the pins are often designed with a taper to facilitate smooth ejection, minimizing the risk of surface defects or part distortion.

Secondly, Adequate lubrication is essential to reduce friction during the ejection process, which not only ensures smoother ejection but also prolongs the life of the mold. We use high-quality, heat-resistant lubricants compatible with the MIM process conditions. Proper lubrication also contributes to the overall efficiency of the mold, as it reduces wear and tear on the ejection components, enabling longer production runs without frequent maintenance, smooth, damage-free ejection processes in MIM mold design.

Cavity Pressure and Temperature Sensors

Cavity pressure sensors provide real-time insights into the molding process. By strategically placing cavity pressure sensors within the mold, they can monitor the pressure exerted on the material during injection. This data lets them promptly detect variations or anomalies in the filling process. If pressure deviations occur, adjustments can be made to optimize the molding parameters, ensuring that each part is manufactured within the desired specifications. Its proactive approach minimizes defects and enhances the efficiency of the MIM process.

Temperature sensors within the mold are equally crucial. Temperature control directly impacts material flow, solidification, and the overall quality of the parts produced. Neway leverages these sensors to monitor and regulate temperature profiles throughout the mold cavity closely. This precision ensures that the material remains within the specified processing temperature range, preventing issues like premature solidification or material degradation. By maintaining tight control over temperature, Neway can consistently produce parts with the high precision and material integrity required for industries such as aerospace and medical devices.

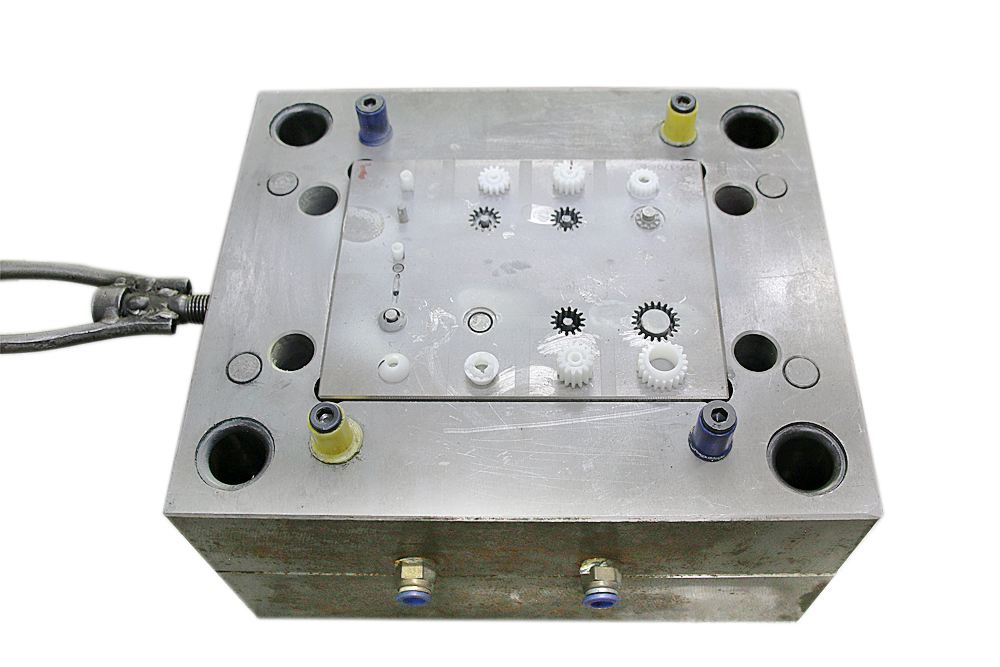

Mold Cavities

Designing mold cavities is critical to Metal Injection Molding (MIM) mold design. Neway's approach to this process is guided by several vital tips that ensure the production of high-precision components. Firstly, Neway emphasizes the importance of precision and attention to detail in cavity design. We meticulously analyze the part geometry and material characteristics to determine the optimal cavity layout. It involves considering factors like gate placement, runner design, and the positioning of cooling channels. By optimizing the cavity design, Neway ensures that the material flows evenly and fills the mold cavity without interruptions or defects.

Secondly, we aim to balance achieving high precision and efficiency in mold cavity design. It involves designing appropriately sized cavities to match the part's requirements, avoiding unnecessary excess material. Additionally, Neway considers strategies such as multi-cavity molds to increase production output while maintaining consistent quality.

Mold Maintenance

The primary reason for mold maintenance is to ensure the longevity and optimal performance of the molds. Molds are subjected to extreme conditions during production, including high temperatures, pressures, and repeated cycles. Without regular maintenance, molds can deteriorate, leading to defects in the produced parts, increased downtime, and costly repairs or replacements. By conducting routine maintenance, manufacturers like Neway can identify and address issues early, preventing more significant problems and prolonging the lifespan of the molds.

Furthermore, mold maintenance is essential for upholding quality standards. In precision manufacturing processes like MIM, even the slightest deviation in mold dimensions or surface conditions can result in defects in the final components. Regular maintenance helps maintain the molds' precision, ensuring that each part produced meets the specified tolerances and quality criteria.

What We Can Do In Metal Injection Molding?

We can provide a one-stop service from prototyping to mass production for your custom injection molded parts. this includes