What metals can be effectively used in sand casting?

Introduction

Sand casting remains one of the most versatile and cost-effective manufacturing methods for producing complex metal parts. Its adaptability to a wide range of metals and alloys makes it ideal for industries such as automotive, energy, and power tools manufacturing. The key to optimizing performance lies in choosing the right alloy based on mechanical strength, thermal conductivity, corrosion resistance, and casting behavior.

Aluminum Alloys

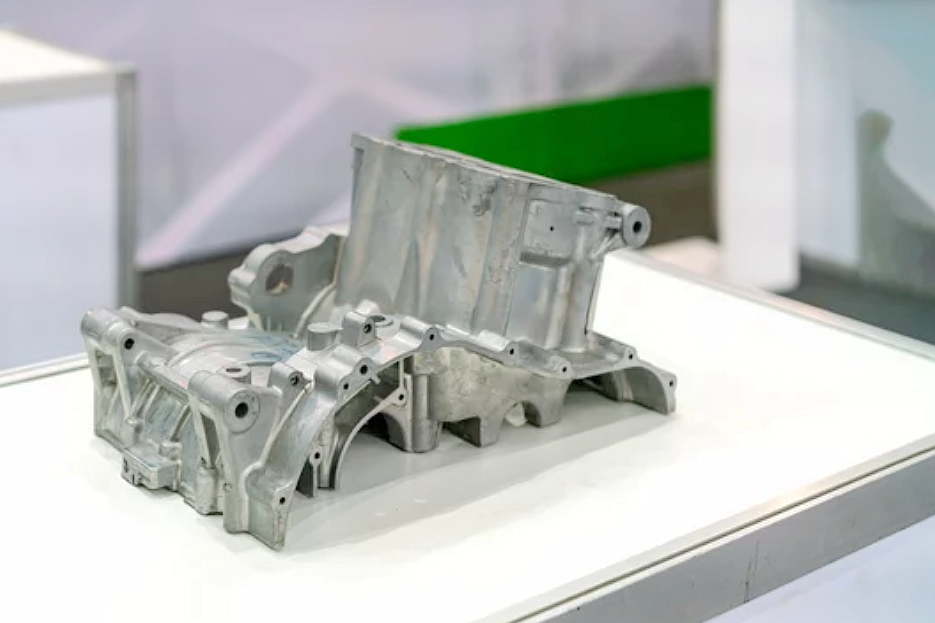

Aluminum alloys are among the most commonly used metals in sand casting due to their excellent castability, light weight, and good corrosion resistance. Grades such as A356 and A380 offer a strong balance between strength and machinability, while 383 (ADC12) and B390 are preferred for high-wear applications, including engine blocks and transmission housings. Aluminum also allows for post-treatments such as anodizing and powder coating, which improve both durability and appearance.

Cast Iron

Cast iron is another cornerstone of sand casting, valued for its exceptional vibration damping and high compressive strength. It is ideal for heavy machinery bases, pumps, and engine components. Variants like gray and ductile iron provide specific advantages—gray iron for superior machinability and ductile iron for improved toughness. Despite its brittleness, its low melting point makes it highly economical for large-scale production.

Stainless Steel and Carbon Steel

Cast stainless steel and carbon steel are used when corrosion resistance and structural strength are critical. Stainless steel offers durability in high-temperature and corrosive environments, making it suitable for valves, marine hardware, and food-processing equipment. Carbon steel offers an excellent balance of hardness and affordability, making it a popular choice for use in construction and industrial machinery.

Copper and Its Alloys

Copper alloys, including bronze and brass, are highly effective for sand casting because of their superior electrical and thermal conductivity. These materials are widely used in telecommunication and energy systems where high conductivity and wear resistance are essential. Copper-based castings also display excellent corrosion resistance, especially in marine and outdoor environments.

Zinc and Magnesium Alloys

Although less common in sand casting compared to zinc die casting or gravity casting, certain zinc alloys and magnesium alloys can still be effectively cast in sand molds. These metals offer a strong strength-to-weight ratio and are used in applications where lightweight performance is key, such as e-mobility components and small enclosures.

Conclusion

From lightweight aluminum and durable steel to conductive copper and robust iron, sand casting supports an extensive array of metals tailored for performance, cost, and environmental demands. When paired with post-process treatments like heat treatment or painting, these alloys deliver both functional precision and long-term resilience for critical industrial components.