How do Neway’s standards align with ISO and regulatory requirements?

Neway’s internal standards are structured to align with internationally recognized quality and regulatory expectations across automotive, e-mobility, aerospace, medical device, and other critical industries. From advanced APQP-style planning and traceability to process validation and material control, our manufacturing and documentation practices are designed to support customer compliance with ISO-based management systems and sector-specific regulations.

System-Level Quality and Traceability

At the system level, Neway manages projects under a structured quality framework that mirrors the intent of ISO management standards: risk-based thinking, documented procedures, and continuous improvement. For multi-technology programs that combine molding, casting, and sheet metal, our custom parts manufacturing service coordinates process flows, control plans, and traceability records from RFQ to SOP.

Material and batch traceability are supported through controlled sourcing and documentation across the full materials available portfolio, including metals, polymers, and ceramics. This enables full lot-level traceability and supports customer PPAP, FAIR, or medical device DHR documentation as required.

Process Validation and Special Process Control

Core manufacturing processes are validated through capability studies (Cp/Cpk), DOE, and structured trials. For complex geometries and functional surfaces, Neway leverages injection molding, metal injection molding, and precision casting with documented process windows and critical parameter monitoring.

For lightweight structural parts, aluminum die casting and sheet metal fabrication are validated against dimensional, mechanical, and porosity requirements defined in customer or ISO-based specifications. Special processes, such as heat treatment and passivation, are controlled through documented procedures, certification of furnace cycles or baths, and test coupons as required.

Industry-Specific Regulatory Expectations

In the automotive and e-mobility sectors, Neway supports customer compliance with functional safety and OEM specifications by combining robust process control with full dimensional and material reports. Structural components in cast alloys and cast stainless steel are validated for fatigue and corrosion performance to align with vehicle durability and safety targets.

For medical device programs, material selection and cleanliness requirements are addressed with controlled polymers such as Ultem (PEI) and metal grades like stainless steel for PIM/MIM, supporting biocompatibility and sterilization compatibility requirements defined in international standards and customer-specific protocols.

In aerospace and energy, high-temperature parts produced in nickel-based alloys and superalloys undergo tighter NDT, dimensional, and mechanical test regimes consistent with turbine, engine, or high-pressure applications.

Surface Integrity and Corrosion Protection

Surface treatments are selected and validated to satisfy both functional and regulatory requirements, including corrosion resistance, electrical performance, and cosmetic quality. Aluminum structures can be protected via anodizing or powder coating, while conductive or decorative layers are achieved through electroplating. Deburring and edge-quality requirements are addressed using controlled tumbling processes with documented media and cycle parameters.

Prototyping, Testing, and Documentation

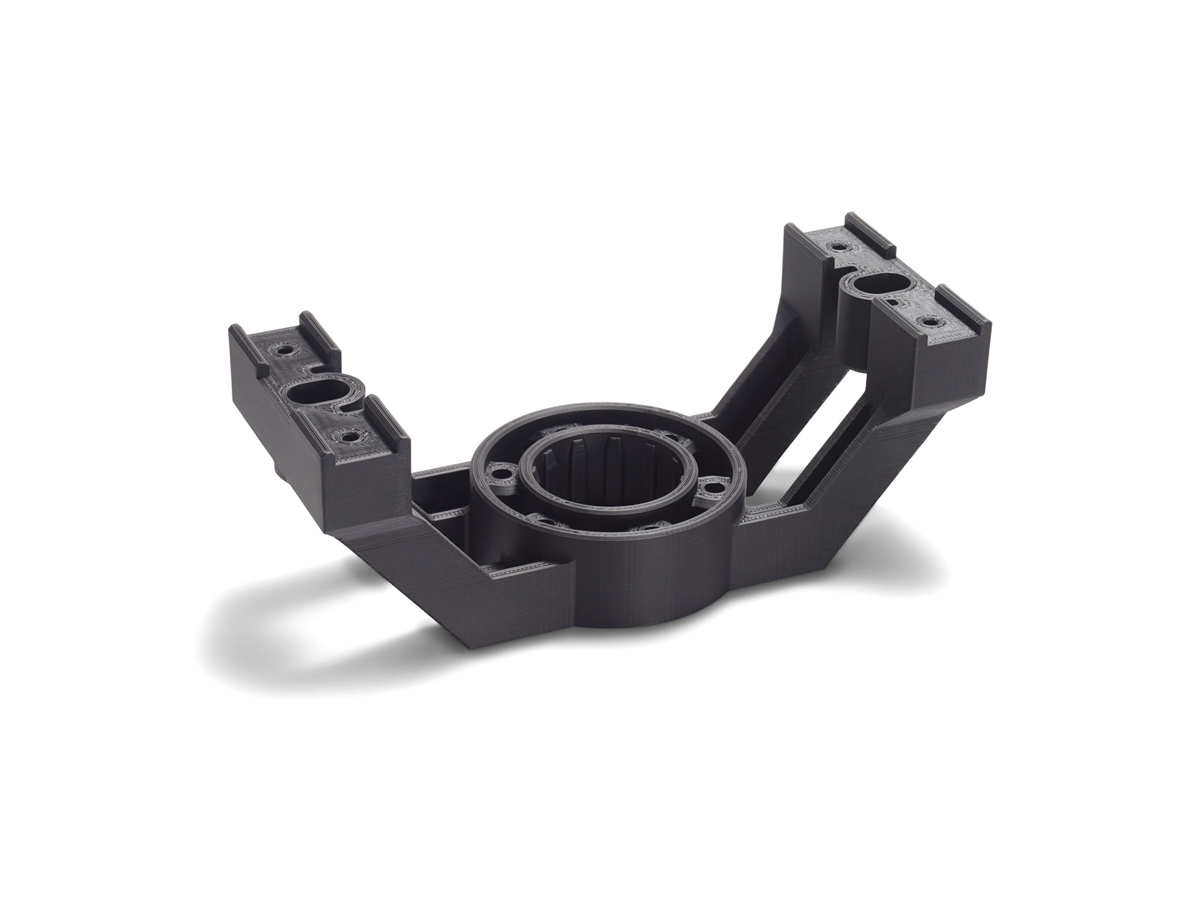

Before SOP, prototypes are produced using CNC machining prototyping, 3D printing prototyping, and rapid molding prototyping to validate design, process capability, and testing methods. Dimensional reports, capability data, and material certificates are compiled to support customer audits and regulatory submission packages, ensuring that the final series process remains aligned with ISO-style quality management and sector-specific requirements.