What is the shortest lead time to a fully tested drivetrain prototype?

The shortest lead time to a fully tested drivetrain prototype depends on how early material selection, manufacturing feasibility, and simulation-driven design are aligned. With a streamlined development flow that involves rapid prototyping, functional testing, and integrated validation, Neway can deliver drivetrain prototypes in as little as 4–6 weeks for simplified assemblies and 8–12 weeks for complex, multi-stage systems used in e-mobility and automotive applications.

Development Path to Fast Prototyping

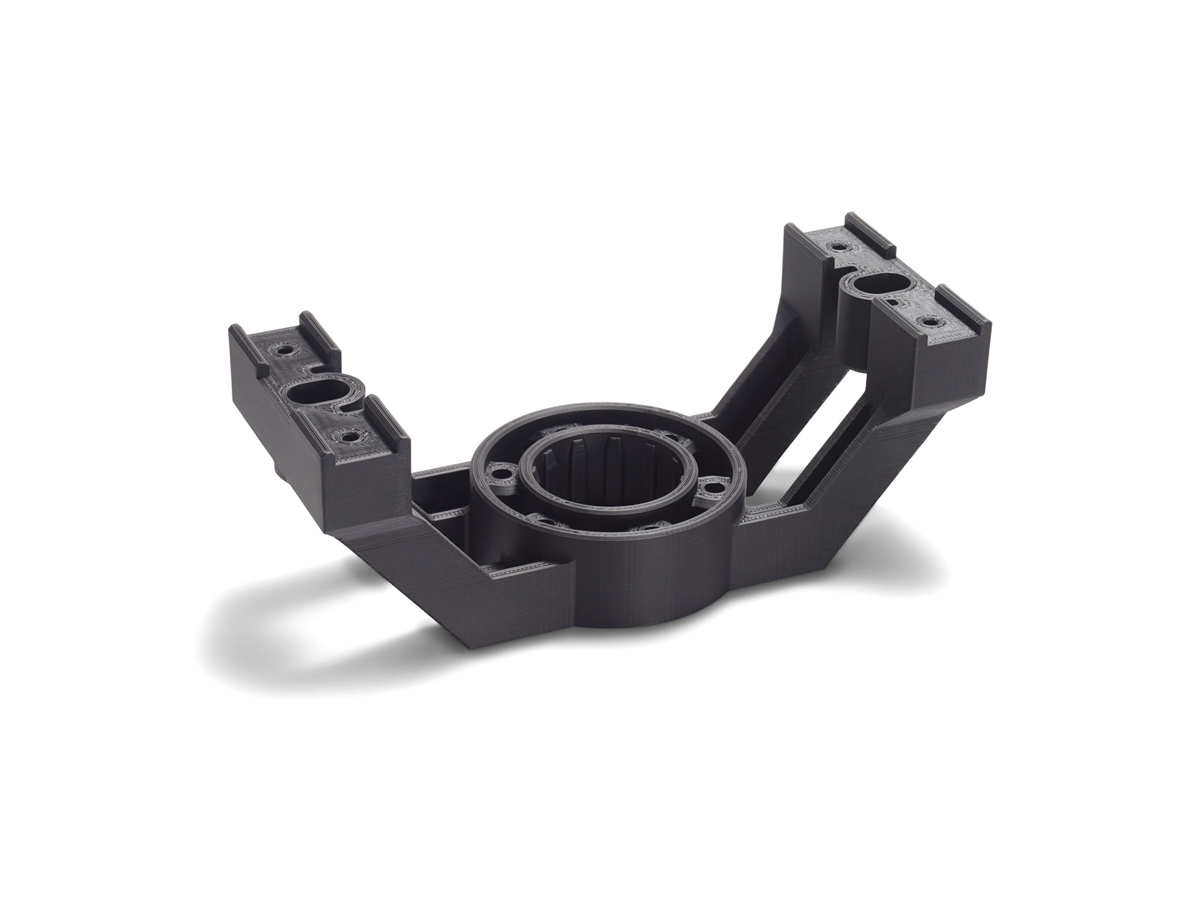

The process starts with CAD and FEA validation, followed by quick-turn manufacturing using CNC machining prototyping for critical rotating components and 3D printing prototyping for geometric evaluation and fit testing. Lightweight housings and covers can be built through plastic injection molding or rapid prototyping to validate assembly interfaces and thermal management early in the development cycle.

For power-transmission elements such as shaft systems, gears, and locking mechanisms, high-strength materials like MIM-4140 or carbon steel via precision casting are often used to simulate actual load cases. These manufacturing routes reduce prototype machining time and ensure functional testing reflects real-world performance.

Testing and Validation Efficiency

To reach full drivetrain validation within weeks, Neway performs NVH, wear, and torque cycling tests on pre-production prototypes. Thermal management can be assessed using housings produced via aluminum die casting or gravity casting. Joining strategies such as overmolding and insert molding enable hybrid assemblies that reduce part count and allow faster iteration cycles.

Surface durability is also validated using heat treatment, sandblasting, and powder coating to confirm that lightweight parts can withstand fatigue, vibration, and temperature cycles during long-term operation.

Recommended Prototyping Sequence

Digital validation via CAD + FEA

Rapid geometry & fit assessment via 3D printing

Functional part production via CNC machining & MIM

Assembly validation and thermal testing using injection-molded housings

Full drivetrain testing—NVH, torque, endurance, and fatigue

Lead Time Summary

Simple drivetrain prototype: **4–6 weeks**

Full functional drivetrain with validation testing: **8–12 weeks**

Advanced multi-speed or hybrid systems: **12–16+ weeks** depending on testing requirements