What factors most significantly impact the cost of custom metal stamping?

Key Cost Drivers in Custom Metal Stamping

The cost of custom metal stamping is determined by a combination of factors, including tooling complexity, material selection, production volume, and downstream finishing requirements. Understanding these factors enables manufacturers to optimize their designs, select the most suitable processes, and align budgets with performance expectations. Before stamping begins, upstream fabrication methods such as sheet metal fabrication and precision cutting technologies like laser cutting play a major role in defining both material efficiency and manufacturability. The forming integrity also depends on supplementary operations such as metal bending and specialized tooling used in sheet metal stamping. Early-stage validation supported by prototyping ensures design feasibility before investing in production dies.

Material Selection and Its Influence on Cost

The choice of material has one of the largest impacts on total stamping cost. Harder or corrosion-resistant alloys require stronger tooling and generate greater tool wear. Commonly used alloys include stainless steel for structural applications, carbon steel when the strength-to-cost ratio is crucial, and copper alloys for electrical components. Lightweight alloys such as cast aluminum and multi-industry metals like zinc alloy also influence cost based on thickness, formability, and availability. Higher-strength or specialty materials typically increase both tooling cost and required press tonnage.

Industries such as automotive use thicker steels for structural brackets, while consumer electronics favor thin copper or aluminum for EMI shielding. The telecommunication sector often requires tight-tolerance stamped components, which further raises tooling precision demands.

Tooling Complexity and Dimensional Requirements

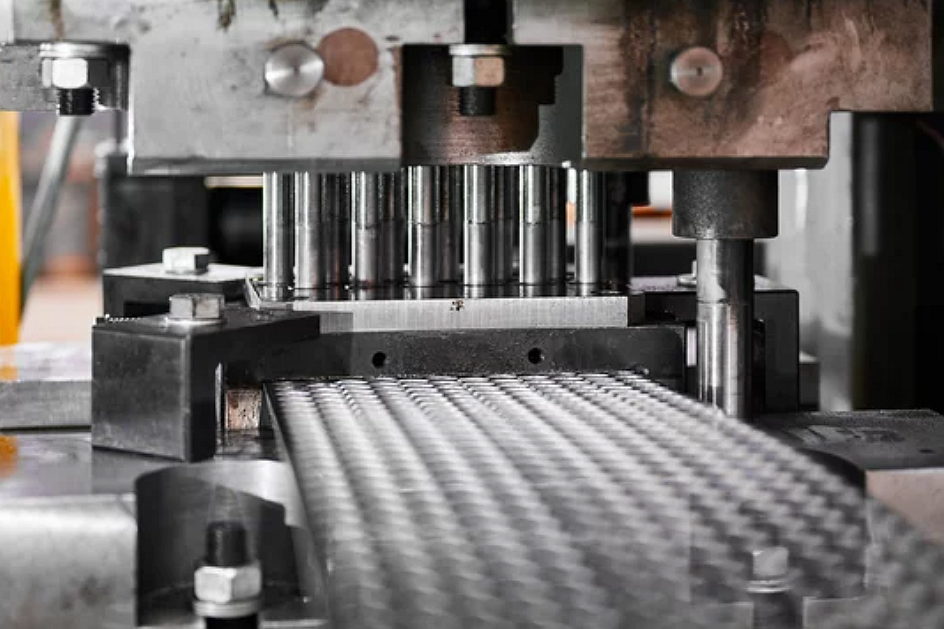

Progressive and compound dies vary significantly in cost based on their geometry, the number of forming stages, and the tolerance requirements. Parts requiring multiple bends, deep draws, or embossing increase die complexity. High-precision features must be consistently achieved throughout the tool’s lifetime, which often necessitates the use of premium die steels and secondary adjustments during commissioning. The correlation is simple: the more operations integrated into the tool, the higher the tooling cost—but the lower the unit cost at scale.

Production Volume and Machine Requirements

Large production volumes reduce unit costs because the initial die investment is amortized across a greater number of parts. Conversely, low volumes may not justify the use of complex tooling, prompting manufacturers to adopt simpler dies or validation steps before committing to full-scale stamping. Required press tonnage also affects cost. Thick or high-strength alloys demand more powerful presses, which increases operating expenses.

Surface Finishing and Post-Processing

Surface finish expectations can add significant cost. Stamped metal parts used in consumer-facing or corrosion-sensitive applications often undergo additional treatments such as anodizing or protective coatings like powder coating. These operations enhance durability and appearance, but they also increase the overall processing time and cost.