Metal Mastery: Leveraging Material Versatility in Sand Casting for Superior Performance

Introduction

Sand casting is one of the oldest and most versatile metal casting processes, highly valued for its adaptability in producing a diverse range of metal components. By mastering the versatility of available casting materials, manufacturers can optimize product performance, enhance durability, and achieve cost-effectiveness. In this blog, we'll explore the advantages of material versatility in sand casting, its performance impact, and practical applications across various industries.

Understanding Sand Casting and Material Versatility

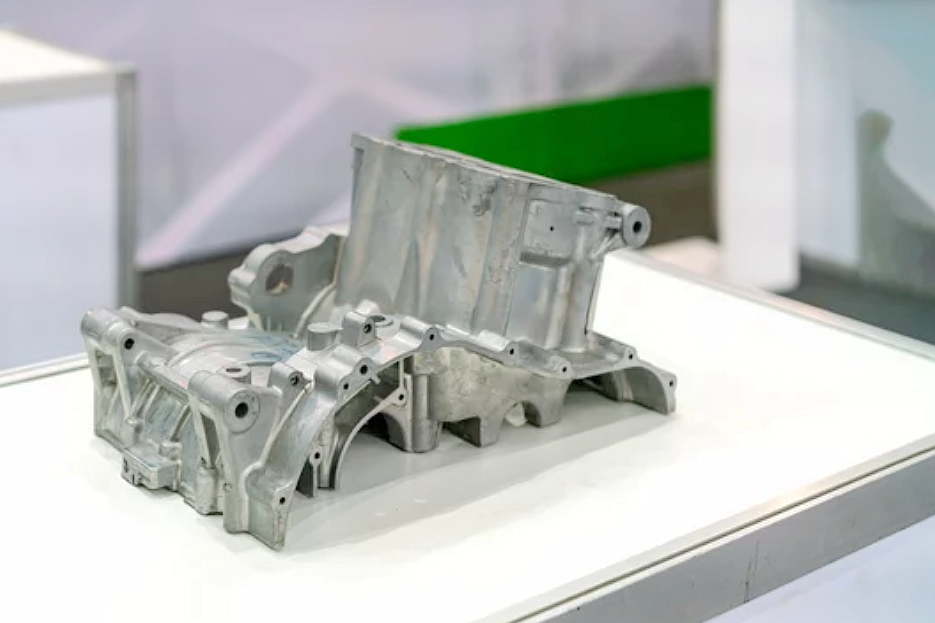

Sand casting involves pouring molten metal into a precisely shaped sand mold, where it solidifies to form complex parts. Its flexibility allows for the use of diverse metals, including robust materials like cast aluminum and strong, corrosion-resistant cast stainless steel. Compared to methods like die casting or investment casting, sand casting uniquely accommodates a wider range of metals and alloys tailored to specific industrial needs.

Advantages of Material Versatility in Sand Casting

Flexibility in Metal Selection

Sand casting offers unmatched flexibility in metal choice, allowing manufacturers to select metals that precisely match their performance requirements. Whether prioritizing strength, durability, or corrosion resistance, options such as carbon steel or bronze alloys ensure ideal outcomes.

Customization of Mechanical Properties

Manufacturers can experiment with alloy compositions easily, optimizing mechanical properties such as tensile strength, ductility, and conductivity. This customization capability is crucial for achieving targeted performance metrics in sectors such as automotive and aerospace.

Cost-Effectiveness and Adaptability

Selecting appropriate and economical metals significantly reduces production costs without sacrificing quality. Sand casting’s adaptability makes it especially advantageous for prototyping and low-volume manufacturing, allowing cost-effective experimentation and iterative improvement.

Ease of Experimentation

The sand casting process facilitates the rapid prototyping and testing of new alloy combinations, thereby accelerating innovation and enhancing product development efficiency. Companies, such as those in the energy and heavy machinery sectors, utilize this ease of experimentation to enhance reliability and performance.

Real-World Applications Highlighting Material Versatility

Automotive Industry

Sand casting is widely used in the automotive sector for critical parts, such as engine blocks and transmission housings. Metals such as iron and cast aluminum are chosen for their strength, durability, and weight efficiency, significantly enhancing vehicle performance and fuel economy.

Industrial Machinery and Heavy Equipment

Components for heavy machinery, including gears, pump housings, and structural frameworks, often rely on sand casting. Robust materials like low-alloy steel and iron ensure these parts withstand heavy-duty operational stresses, maximizing equipment reliability and longevity.

Construction and Infrastructure

Sand casting produces essential components for infrastructure, including valves and structural fittings. Utilizing strong, corrosion-resistant materials, such as cast stainless steel and carbon steel, enhances the safety, stability, and longevity of infrastructure projects.

Marine and Aerospace

The marine and aerospace sectors rely heavily on sand casting for producing high-performance parts that require corrosion resistance and structural integrity. Selecting specialized alloys, such as bronze and aluminum, ensures exceptional performance in marine environments and reduces weight in aerospace components, thereby boosting fuel efficiency.

Enhancing Product Performance through Material Selection

Choosing the optimal material directly influences product performance and lifespan. A detailed analysis of metal properties enables manufacturers to tailor products precisely to their operating conditions and consumer expectations. For instance, high-strength alloys like steel are ideal for equipment subjected to heavy loads, while lighter aluminum alloys offer superior solutions for mobility-focused sectors, such as the automotive or e-mobility industries.

Overcoming Material-Related Challenges in Sand Casting

Common Challenges

Different metals present specific casting challenges, including variable melting temperatures, fluidity, shrinkage rates, and cooling behavior, which can potentially lead to defects such as porosity or dimensional inaccuracies.

Best Practices

Effective strategies include precise process control, detailed mold designs, and stringent temperature regulation. Employing rigorous quality control measures and frequent testing helps manufacturers maintain consistent and defect-free casting outcomes.

Importance of Metallurgical Expertise

Working closely with metallurgical specialists significantly enhances casting results. Expert knowledge guides alloy selection, addresses metallurgical complexities, and proactively manages defects, ensuring superior product quality and reliable performance.

Future Trends in Material Versatility and Sand Casting

Innovations in Alloy Development

Continuous advances in alloy technology are expanding the capabilities of sand casting. New alloys offering increased strength, corrosion resistance, and lighter weights are emerging, empowering manufacturers to meet evolving industry-specific demands.

Impact of Advanced Technology

Integrating advanced simulation software, robotics, and automation technology further enhances the precision of sand casting. These advancements accurately predict metal behavior, optimize mold design, and reduce production defects, thereby significantly improving manufacturing efficiency.

Emerging Market Opportunities

The versatility of sand-casting materials creates substantial opportunities in new sectors, including renewable energy, electric vehicles, and advanced aerospace. Manufacturers who effectively leverage a diverse range of metal choices will secure competitive advantages in these rapidly growing markets.

Conclusion

Sand casting's exceptional material versatility significantly elevates product performance, durability, and cost-effectiveness across numerous industries. Mastering the selection and use of appropriate metals empowers manufacturers to precisely meet diverse performance requirements. Companies embracing material versatility in sand casting are well-positioned for sustainable growth, ongoing innovation, and market leadership.