Innovative Lightweight Enclosures for Electronic Devices

Innovative Lightweight Enclosures: Leading a New Trend in Electronic Device Design

In today’s rapidly evolving electronics industry, lightweight enclosures have become a key factor in enhancing product competitiveness. As the engineering team at Neway, we understand that superior enclosure design must achieve the perfect balance between weight, strength, heat dissipation, and aesthetics. From portable devices to fixed installations, lightweight enclosures not only improve user experience but also provide more effective protection for internal components.

Advanced Manufacturing Processes Enabling Lightweight Innovation

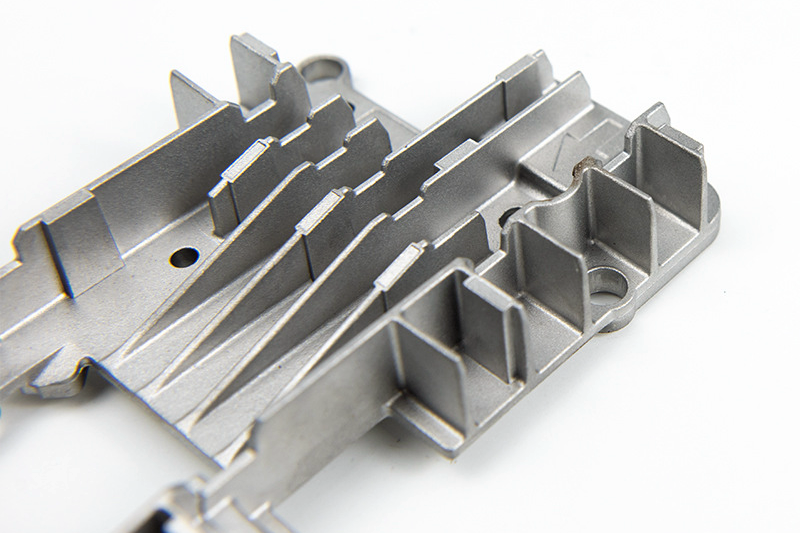

Aluminum Die Casting: An Excellent Balance of Strength and Lightweight

The aluminum die casting process delivers outstanding structural strength while pursuing lightweight design. It is particularly suitable for manufacturing enclosures with complex geometries, ensuring overall rigidity while maintaining minimal wall thickness. With our advanced die casting technology, we can achieve thin-wall structures of less than 1.2 mm, resulting in a weight reduction of more than 30% compared to traditional machining methods. For devices requiring efficient heat dissipation, aluminum’s thermal conductivity makes it an ideal choice, enabling both weight reduction and effective heat transfer.

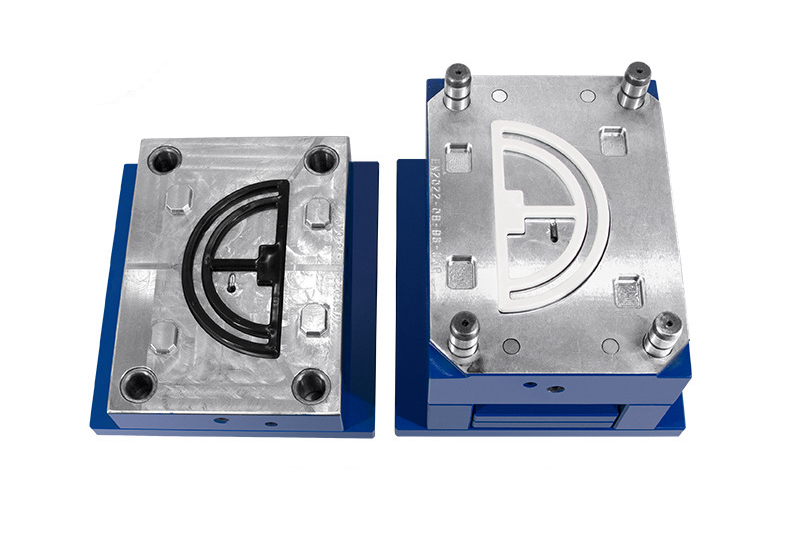

Precision Injection Molding: The Art of Complex Design and Mass Production

In the field of plastic enclosure manufacturing, our plastic injection molding services offer limitless design possibilities. By leveraging advanced technologies such as gas-assisted molding, we can optimize wall thickness to further reduce weight while maintaining structural integrity. For consumer electronics, we can produce precision housings with wall thicknesses as low as 0.6 mm, achieving Class A surface quality. This process is particularly suitable for applications that require high consistency in large-scale production, ensuring every product meets the same high-quality standards.

Metal Injection Molding: Unlocking Complex Micro Metal Enclosures

For compact electronic devices, our Metal Injection Molding (MIM) services provide a unique solution. This technology is particularly well-suited for producing micro metal enclosures and structural parts with complex features, performing exceptionally in products such as wearables and portable medical instruments. MIM enables highly intricate internal structures that are difficult to achieve via conventional machining, delivering significant lightweight benefits while maintaining precision.

Sheet Metal Forming and Fabrication: A Perfect Combination of Cost Efficiency and Strength

For applications that require a balance between cost and performance, sheet metal fabrication provides an economical and efficient solution. Using advanced laser cutting and precision bending technologies, we produce lightweight yet robust enclosure components. This process is particularly suitable for network equipment and industrial control cabinets that require excellent electromagnetic shielding, delivering weight reduction without compromising structural integrity.

Beyond the Basics: Surface Treatment Technologies That Add Functionality to Enclosures

Enclosure surface treatments are not only about appearance but also an extension of functionality. Anodizing offers a wide range of color options, forming a hard, protective layer on aluminum enclosures that significantly improves wear and corrosion resistance. For applications requiring extra protection, powder coating delivers a uniform and durable surface finish suitable for harsh environments. For plastic enclosures, In-Mold Decoration (IMD) technology enables the creation of complex patterns and textures while preventing wear issues associated with traditional printing methods.

Core Material Selection for Lightweight Enclosures

Aluminum and Magnesium Alloys: Benchmarks for Metal Lightweighting

In metal material selection, A380 aluminum alloy is a preferred choice for die casting due to its excellent fluidity and mechanical properties. It offers a strong strength-to-weight ratio, ideal for thin-wall and complex structures. For applications requiring even greater weight reduction, magnesium alloys offer a lighter alternative, with a density approximately one-third lower than that of aluminum, along with superior damping and electromagnetic shielding performance.

High-Performance Engineering Plastics and Composites

On the plastics side, polycarbonate is widely used for enclosures thanks to its outstanding impact strength and transparency. For applications with higher requirements in thermal resistance and mechanical performance, PEEK offers exceptional performance, with continuous service temperatures up to 250°C and excellent flame-retardant properties. With proper structural design, these high-performance engineering plastics can achieve metal-like mechanical performance while significantly reducing weight.

Innovative Applications of Lightweight Enclosures Across Electronic Devices

Consumer Electronics and Mobile Devices

In the consumer electronics sector, lightweight enclosures directly influence product portability and user experience. Through material optimization and structural innovation, we help customers achieve lighter, thinner, and more robust designs. From smartphone mid-frames to laptop housings, every detail is carefully engineered and validated to ensure reduced weight without compromising perceived quality or durability.

Telecommunications and Networking Equipment

With the advent of 5G, higher demands are placed on telecommunication equipment enclosures. Our enclosure solutions focus not only on lightweighting but also on enhancing thermal management and electromagnetic shielding performance. Through optimized structural design and material selection, we ensure stable operation under harsh conditions while maintaining ease of installation and maintenance.

E-Mobility and Energy Sectors

In the e-mobility and energy sectors, lightweight enclosures play a vital role in improving energy efficiency. Our solutions for lightweight enclosures used in battery management systems, charging equipment, and energy storage systems not only meet stringent protection ratings but also contribute to overall system efficiency by reducing weight.

Industrial and Medical Equipment

For medical equipment, lightweight enclosures significantly enhance portability and usability. We strictly follow industry standards and regulatory requirements to deliver enclosure solutions that are both lightweight and compliant with hygiene and safety demands. From handheld diagnostic tools to portable monitoring devices, we help manufacturers create products that are more ergonomic and user-friendly.

Choose Neway to Build Exceptional Lightweight Enclosures for Your Products

At Neway, we not only offer advanced manufacturing processes but, more importantly, deliver comprehensive solutions. From material selection and structural optimization to every step of the production process, our engineering team collaborates closely with customers to ensure the final product strikes an optimal balance between weight, performance, cost, and lead time. With our extensive industry experience and rigorous quality control system, we provide full support from prototyping to mass production.

Conclusion: Using Lightweight Innovation to Lead the Future of Electronic Device Design

Lightweight enclosures are not only a reflection of technological progress but also a testament to a deep understanding of user needs. As electronics continue to advance toward greater portability and performance, choosing the right lightweight solution becomes increasingly critical. With comprehensive manufacturing capabilities, in-depth material knowledge, and strong technical expertise, Neway is committed to helping customers develop the next generation of leading electronic devices. Let us work together to push the boundaries of electronic device design.