Durable & Aesthetic Covers for Consumer Electronic Products

Durability and Aesthetics: The Dual Pursuit for Consumer Electronic Enclosures

In today’s highly competitive consumer electronics market, product enclosures have long surpassed a purely protective role and become a core element of brand identity and user experience. As the engineering team at Neway, we deeply understand that a great enclosure design must strike the perfect balance between durability and visual appeal. From smartphones to wearables, from smart home devices to audio products, the enclosure of every successful product is a seamless integration of engineering excellence and design aesthetics.

Core Manufacturing Technologies for Durable Enclosures

Reinforced Structural Design: Enhancing Durability from Within

At Neway, we firmly believe that outstanding durability begins with thoughtful structural design. Through our professional custom parts manufacturing services, our engineering team uses advanced CAE analysis tools to fully evaluate mechanical performance under various real-world conditions at the early design stage. By strategically placing ribs, optimizing fillet transitions, and precisely controlling the distribution of wall thickness, we significantly enhance both impact resistance and deformation resistance. This data-driven design approach ensures that every product maintains excellent structural integrity during daily use.

High-Precision Injection Molding: Ensuring Structural Integrity and Consistency

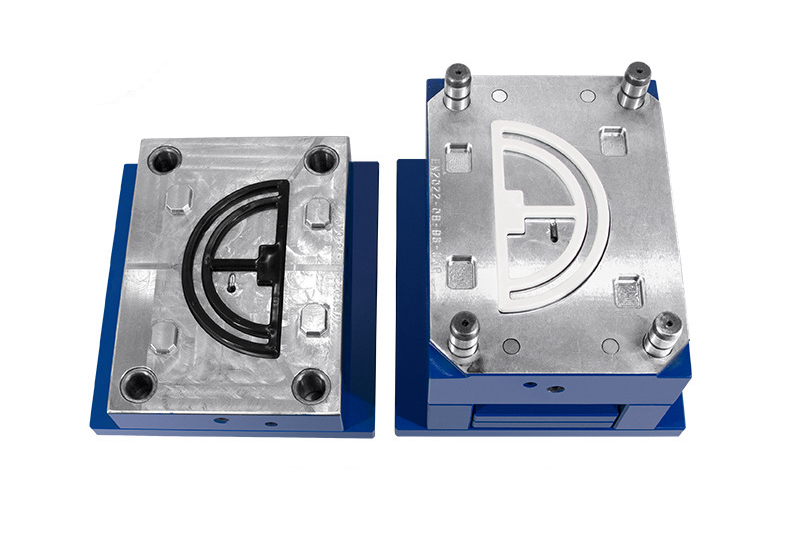

Our plastic injection molding services utilize world-class molding equipment and precision tooling to ensure that each enclosure component delivers outstanding dimensional stability and mechanical performance. By precisely controlling temperature, pressure, and cooling parameters throughout the molding process, we effectively prevent defects such as stress concentration, sink marks, and flash. This rigorous process control not only guarantees consistency in mass production but also ensures that every enclosure meets the demanding durability standards defined at the design stage.

Metal Forming Technologies: Providing Superior Protection

For applications requiring higher strength and durability, we offer advanced metal forming solutions. The aluminum die casting process enables the production of robust housings with complex internal structures, delivering excellent protection while maintaining a lightweight design. Additionally, our Metal Injection Molding (MIM) services are particularly well-suited for manufacturing small, precision metal enclosures that offer superior wear resistance and overall strength, making them ideal for high-end wearables and portable electronic devices.

Surface Treatment Processes That Realize Aesthetic Expression

Premium Metal Finish Solutions

For metal enclosures, we offer a range of premium surface treatment options. Anodizing not only provides rich and long-lasting color options but also forms a hard, wear-resistant protective layer on aluminum surfaces. For products seeking the ultimate metallic texture, Physical Vapor Deposition (PVD) technology provides authentic metallic luster and color, along with excellent wear and corrosion resistance.

Refined Plastic Surface Appearances

The aesthetic quality of plastic enclosures is equally important. Our In-Mold Decoration (IMD) technology enables the integration of complex patterns, textures, and color effects directly during the injection molding process, resulting in a seamless visual experience. For applications that require a metallic appearance while controlling costs, electroplating provides a realistic, metal-like finish with excellent economic efficiency.

Material Science Behind Balancing Durability and Aesthetics

High-Performance Engineering Plastics

Material selection is a crucial factor in striking a balance between robustness and appearance. Polycarbonate (PC), with its excellent impact strength and transparency, is an ideal choice for applications that require both durability and visual appeal. For applications demanding higher mechanical strength and wear resistance, Nylon (PA) provides a reliable solution, and its good compatibility with various surface treatments supports refined aesthetic finishes.

Metal Material Selection

In terms of metal materials, stainless steel, with its exceptional strength and corrosion resistance, is a preferred choice for premium electronic products. For aluminum alloys requiring good formability and surface finishing performance, we recommend A380, which offers an optimal balance among strength, weight, and cost.

Practical Applications of Durable and Aesthetic Enclosures in Consumer Electronics

Mobile Device Enclosures: Slim Yet Strong

In the consumer electronics sector, we collaborate with many leading brands to develop enclosure solutions that are both visually attractive and highly durable for their mobile devices. By optimizing material selection and structural design, we successfully achieve a perfect combination of thinness and robustness. These enclosures perform reliably in daily use and withstand accidental drops and scratches.

Successful Case Studies

Our technical strength has been validated in multiple flagship projects. Our metal injection molding services for Huawei mobile phone accessories demonstrate our expertise in precision metal enclosure manufacturing. At the same time, as an approved metal and plastic injection molding supplier for Apple, we have a profound understanding of top-tier brands’ pursuit of perfection in both quality and aesthetics.

Neway’s One-Stop Solutions: From Concept to Mass Production

At Neway, we offer comprehensive services, spanning from concept design to full-scale production. Our engineering team is involved in the early stages of product development to optimize designs for both aesthetics and manufacturability. With our stringent quality management system and advanced production equipment, we ensure that every enclosure delivered meets the highest quality standards. This end-to-end involvement allows us to provide customers with enclosure solutions that deliver maximum value.

Conclusion: Choose Neway to Create Beautiful Enclosures That Stand the Test of Time

In an era where consumer electronics are increasingly homogeneous, exceptional enclosure design has become a critical means of product differentiation. With deep technical capabilities and extensive industry experience, Neway is committed to helping customers develop enclosures that are both visually stunning and highly durable. We believe that through our professional support, every product can achieve a perfect balance of appearance and performance, standing out in a fiercely competitive market.