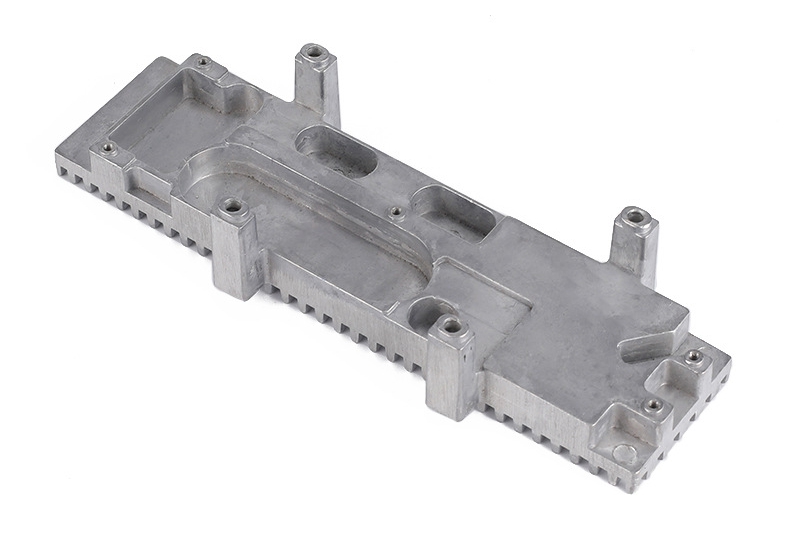

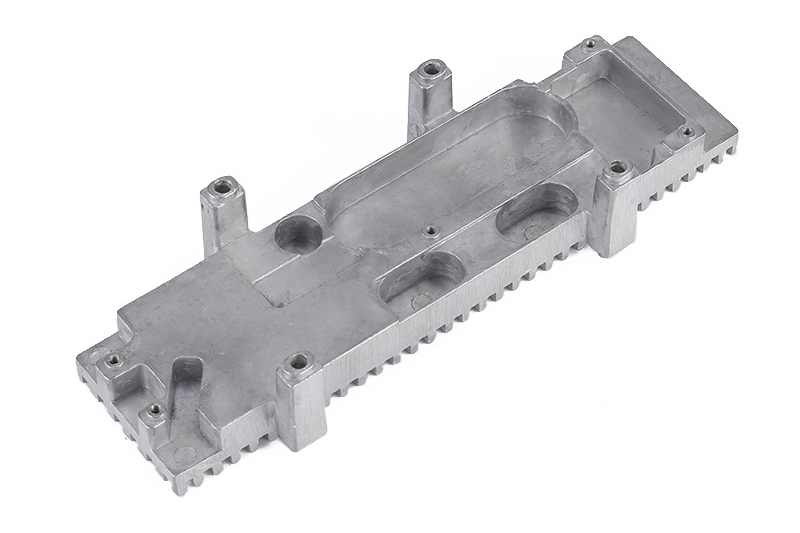

Aluminum A380 Die Casting: Lightweight and Durable Auto Components

The demand for lightweight, durable, and high-performance components is ever-increasing in the automotive industry. Advanced manufacturing techniques, such as high-pressure die casting, are employed to meet these stringent requirements. This blog delves into the process and advantages of using an 800-ton high-pressure die-casting machine to produce large automobile parts from Aluminum A380 alloy.

Aluminum A380 is renowned for its excellent mechanical properties, high strength-to-weight ratio, good thermal and electrical conductivity, and excellent corrosion resistance. These properties make it an ideal choice for manufacturing large, complex automobile parts that can withstand the rigors of automotive use while contributing to overall vehicle weight reduction.

Using an 800-ton press in the die-casting process ensures that the parts produced are of the highest quality, with precise dimensions and smooth finishes. This high-pressure capability creates intricate designs and thin-walled sections critical for modern automotive applications.

In this blog, we will explore the technology behind A380 die casting, the detailed steps involved in achieving the desired surface finish, and the challenges faced during the manufacturing process, such as cold shrink deform. Additionally, we will discuss the solutions implemented, including hot shaping and CNC machining, to ensure the production of top-quality large automobile parts.

A380 Die Casting

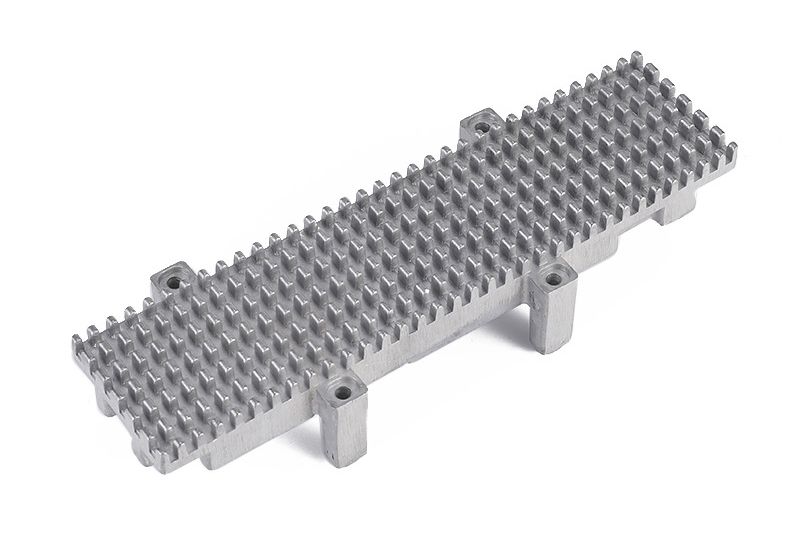

Die casting is a versatile and efficient manufacturing process that produces high-precision metal parts and excellent surface finishes. The A380 die-casting process begins with injecting molten aluminum A380 alloy into a steel mold under high pressure. The 800-ton press capability is crucial in this step, ensuring that the molten metal fills every mold cavity, resulting in highly detailed and accurate parts.

The A380 aluminum alloy is particularly suited for die casting due to its excellent fluidity, allowing it to fill complex molds quickly. Its superior mechanical properties, such as high strength, good thermal and electrical conductivity, and excellent corrosion resistance, make it ideal for producing durable automotive components.

Surface Finish For Aluminum Diecastings

Aluminum Die Casting

The aluminum die-cast parts' surface finish is crucial for aesthetic and functional purposes. The die-casting process typically results in a smooth surface finish. However, additional steps are often required to meet specific quality standards. The molten aluminum A380 alloy is initially injected into a steel mold under high pressure, creating a detailed and precise part. This process inherently reduces surface imperfections compared to other casting methods. However, fine-tuning is necessary for high-end automotive applications.

CNC Machining

Once the part is cast, CNC (Computer Numerical Control) machining is employed to achieve the desired surface finish and precise dimensions. CNC machining involves using automated tools to remove material from the cast part, enhancing its accuracy and smoothness. This step is essential for:

Precision Finishing: CNC machining ensures that critical dimensions and tolerances are met, which is vital for parts that must fit together with other components seamlessly.

Complex Geometries: It allows for creating complex shapes and intricate features that are impossible with die casting alone.

Drilling and Threading: Holes, threads, and other intricate features are added to the part through CNC machining, preparing it for assembly and further processing.

Drilling and Threading

After the initial CNC machining, additional processes like drilling and threading are performed to prepare the part for assembly. These processes ensure that:

Holes are accurately placed for bolts and screws.

Threads are precisely cut to match the corresponding parts, ensuring secure and reliable connections in the final assembly.

Powder Coating

The final step in achieving the desired surface finish is powder coating. This process involves applying a dry powder, typically thermoplastic or thermoset polymer, to the part's surface. The powder is then cured under heat, forming a hard, protective layer. Benefits of powder coating include:

Durability: The coating provides excellent resistance to impact, scratches, and wear, extending the part's lifespan.

Corrosion Protection: It enhances the part's resistance to corrosion, which is crucial for automotive components exposed to harsh environmental conditions.

Aesthetic Appeal: Powder coating offers a uniform and attractive finish and is available in various colors and textures to meet specific design requirements.

The combination of aluminum die casting, CNC machining, drilling and threading, and powder coating ensures that the final product meets stringent quality standards and performs reliably in demanding automotive environments. This comprehensive approach to surface finishing is essential for producing high-quality large automobile parts that are functional and visually appealing.

Automotive Aluminum Diecasting Applications

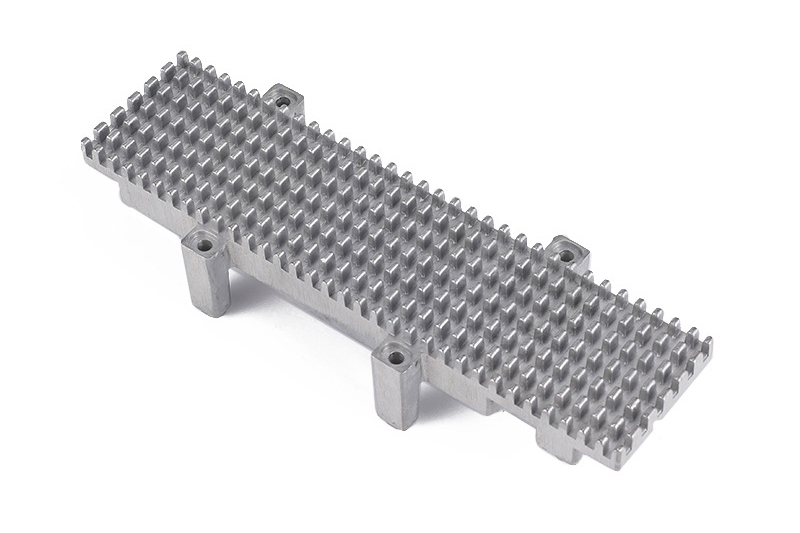

Engine Components

Aluminum A380 die-cast parts are extensively used in engine components due to their excellent strength-to-weight ratio and thermal conductivity. Key applications include:

Engine Blocks: The lightweight nature of aluminum reduces the engine's overall weight, enhancing fuel efficiency and performance.

Cylinder Heads: Aluminum's good thermal conductivity helps dissipate heat effectively, maintaining optimal engine temperatures.

Transmission Housings: The robustness of aluminum A380 ensures that transmission housings can withstand significant mechanical stresses while contributing to the vehicle's overall weight reduction.

Structural Frames

Structural frames and subframes benefit greatly from aluminum A380 die casting. These components are critical for the vehicle's integrity and safety. Applications include:

Front and Rear Subframes: These components provide mounting points for the suspension and help absorb impact in the event of a collision, enhancing safety and stability.

Cross Members and Support Beams: To strengthen the vehicle's chassis, these parts must be lightweight and strong to improve handling and performance.

Transmission Housings

The transmission housing is another critical application of aluminum A380 die casting. These housings must be strong enough to protect the transmission components and lightweight to aid overall vehicle efficiency. Benefits include:

Weight Reduction: Helps improve the vehicle's fuel efficiency and performance.

Durability: Offers excellent resistance to wear and tear, ensuring the transmission operates smoothly over a long period.

Thermal Management: The good thermal properties of aluminum help dissipate heat generated by the transmission components, enhancing their longevity.

Other Applications

Beyond engine components and structural frames, aluminum A380 die casting is used in various other automotive parts:

Suspension Components: Lightweight suspension parts improve vehicle dynamics and ride quality.

Brake System Components: Aluminum brake calipers and other parts help reduce unsprung weight, enhancing handling and performance.

Body Panels and Trim: Aluminum's corrosion resistance and excellent surface finish are ideal for exterior body panels and decorative trim pieces.

Die-Cast Aluminum Parts Industry Applications

Role of Die-Cast Aluminum Parts in Modern Automotive Design

Die-cast aluminum parts are critical in modern automotive design, contributing to vehicle performance, safety, and efficiency advancements. The use of aluminum A380 in die casting offers several key advantages:

Lightweight Construction: The automotive industry constantly seeks to reduce vehicle weight to improve fuel efficiency and reduce emissions. Aluminum A380, with its high strength-to-weight ratio, allows for creating lightweight yet strong components. This weight reduction translates into better fuel economy and lower carbon emissions, aligning with global trends towards more environmentally friendly transportation solutions.

Enhanced Performance: Lightweight aluminum components contribute to better vehicle handling and acceleration. Reduced weight improves the power-to-weight ratio, enhancing overall vehicle performance without compromising safety or durability.

Improved Safety: Aluminum's excellent energy absorption properties enhance vehicle safety. In a collision, aluminum parts can absorb and dissipate impact energy more effectively, protecting passengers and reducing the risk of injury.

Durability and Longevity: Aluminum A380's resistance to corrosion and wear extends the lifespan of automotive components. This durability is essential for parts exposed to harsh operating conditions, such as engine and suspension components.

Trends in the Automotive Industry Favoring Lightweight, Durable Materials

The automotive industry is undergoing significant changes driven by several key trends that favor the use of lightweight, durable materials like aluminum A380:

Electric and Hybrid Vehicles: The shift towards electric and hybrid vehicles (EVs and HEVs) emphasizes the need for lightweight materials to offset the weight of batteries and electric drivetrains. Aluminum A380's lightweight properties are ideal for structural components, battery housings, and other critical parts in EVs and HEVs.

Fuel Efficiency Regulations: Stringent fuel efficiency and emission regulations push automakers to adopt lightweight materials. Reducing vehicle weight is one of the most effective ways to meet these regulations, making aluminum die-cast parts increasingly popular.

Advanced Manufacturing Techniques: Adopting advanced manufacturing techniques, such as high-pressure die casting, enables the production of complex and precise aluminum parts. These techniques enhance automotive components' performance and reliability, driving further industry adoption.

Sustainability: Aluminum is highly recyclable, making it a sustainable choice for automotive manufacturing. The industry's focus on sustainability and reducing the environmental impact of vehicles further drives the use of recyclable materials like aluminum A380.

Challenges And Solutions In HPDC

Cold Shrink Deform

One of the significant challenges in the die casting process, particularly with high-pressure die casting of aluminum A380, is cold shrink deform. This phenomenon occurs during the cooling phase when the molten aluminum solidifies and cools to room temperature. As the metal cools, it contracts. If not appropriately managed, this contraction can lead to dimensional inaccuracies and deformities in the final part, which can compromise the part's integrity and functionality.

Causes of Cold Shrink Deform

Thermal Contraction: Different sections may cool at different rates as the cast part cools, leading to uneven contraction. This can result in internal stresses that cause the part to warp or deform.

Complex Geometries: Parts with intricate designs or varying wall thicknesses are more prone to uneven cooling and, thus, more susceptible to cold shrink deformations.

Inadequate Mold Design: Improper mold design can exacerbate cooling issues. For instance, the risk of deformity increases if the mold does not allow for uniform cooling or lacks adequate cooling channels.

Impact on Automotive Parts

Dimensional Inaccuracies: Parts that do not conform to the specified dimensions can lead to assembly issues, where components do not fit together correctly, resulting in potential failure of the vehicle system.

Structural Integrity: Deformations can weaken the part, making it less capable of withstanding mechanical stresses, which is critical for safety-related components.

Aesthetic Issues: Visible deformities can affect the appearance of exterior parts, which is undesirable in automotive applications where aesthetics are essential.

Managing Cold Shrink Deform

Addressing cold shrink deformations requires advanced techniques and careful process control. Here are some solutions implemented in the manufacturing process:

Hot Shaping

Aluminum die-casting hot shaping is used to counteract the effects of cold shrink deform. It involves reheating the part after initial cooling and applying controlled deformation to return it to the desired shape. The process includes:

Reheating: The part is uniformly reheated to a specific temperature that allows for plastic deformation without affecting the microstructure of the aluminum.

Controlled Deformation: Mechanical forces are applied to reshape the part accurately. This step must be precisely controlled to avoid over-correcting or introducing new stresses.

CNC Machining

CNC machining is critical in ensuring the part's final dimensions and surface quality. After hot shaping, CNC machining achieves precise tolerances and removes any remaining deformities. The benefits include:

Precision and Accuracy: CNC machining can correct minor dimensional inaccuracies by removing excess material and achieving the exact specifications.

Consistency: Automated CNC machines ensure consistent quality across large production runs, essential for maintaining the integrity and performance of automotive parts.

Enhanced Surface Finish: Besides correcting deformities, CNC machining improves the surface finish, preparing the part for subsequent finishing processes like powder coating.

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.