How are advancements in alloy technology enhancing sand casting capabilities?

Introduction

Modern sand casting continues to evolve in tandem with innovations in alloy development. The integration of advanced aluminum, steel, and nickel-based materials has expanded what’s possible in precision, strength, and thermal performance. These technological breakthroughs have transformed sand casting from a cost-efficient traditional process into a solution capable of producing high-performance components for demanding industries such as aerospace, automotive, and energy.

Improved Mechanical Strength and Durability

Advancements in carbon steel and stainless steel formulations have led to superior tensile strength and fatigue resistance. These alloys minimize internal porosity and enhance dimensional stability under stress, enabling the production of structural and load-bearing components with tighter tolerances. Modern alloying elements such as molybdenum, vanadium, and chromium enhance high-temperature strength, ensuring consistent performance in turbines, engines, and heavy machinery.

Enhanced Corrosion and Oxidation Resistance

New generations of nickel-based alloys and copper alloys offer exceptional resistance to corrosion and oxidation. These improvements allow sand-cast components to operate reliably in harsh chemical, marine, and high-temperature environments. Combined with anodizing, passivation, or plating treatments, these alloys significantly extend the product's lifespan and maintain surface integrity.

Lightweight High-Performance Aluminum and Magnesium Alloys

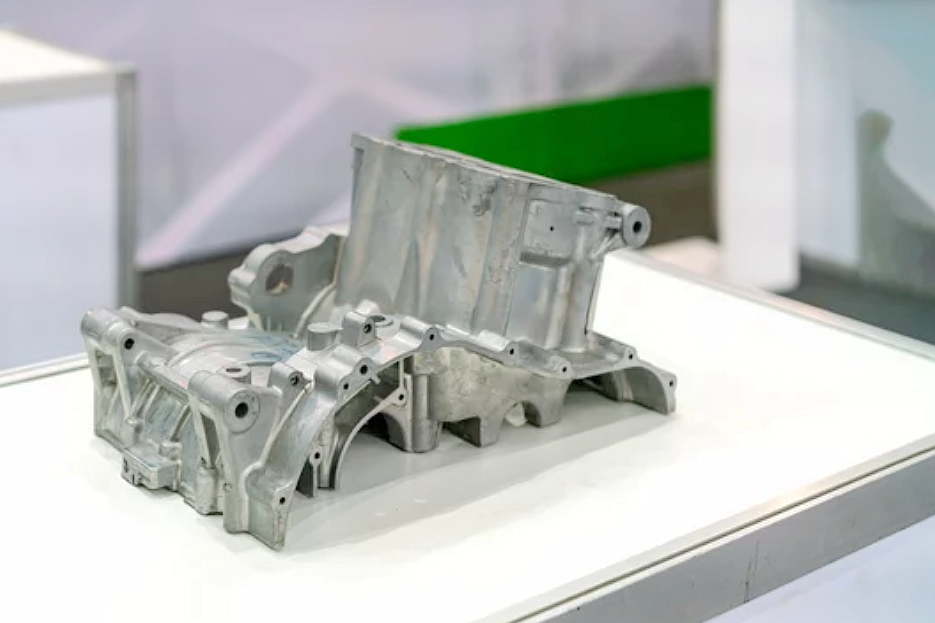

The development of advanced aluminum alloys, such as A356, and magnesium alloys has enabled the production of lightweight, high-strength parts ideal for e-mobility and aerospace structures. These alloys combine excellent castability with reduced density, resulting in improved fuel efficiency and load capacity. Alloy refinements have also mitigated problems such as hot cracking and gas porosity, enabling more consistent casting outcomes.

Better Heat and Wear Resistance

Modern high-temperature alloys, particularly nickel-chromium and tool steel formulations, offer exceptional wear and creep resistance. When paired with heat treatment and nitriding, these materials can maintain their hardness and dimensional accuracy in extreme service conditions, such as those encountered in turbines, valves, or molds exposed to cyclic loading.

Improved Castability and Surface Quality

New alloy compositions with refined grain structures have improved fluidity, reducing misruns and cold shuts. Enhanced metallurgical control allows smoother surfaces even before finishing. When followed by polishing or electropolishing, sand-cast parts now achieve finishes approaching those of precision-cast or machined components. This advancement minimizes post-processing costs and enhances overall production efficiency.

Sustainable Alloy Development

Emerging alloy systems are also designed for recyclability and lower environmental impact. Aluminum and iron alloys with improved melt recovery rates and reduced oxidation losses align with sustainable manufacturing goals. These developments help industries meet environmental regulations without compromising part performance or quality.

Conclusion

Innovations in alloy technology are redefining the limits of sand casting. Stronger, lighter, and more corrosion-resistant metals, combined with optimized heat treatments and finishing, enable engineers to produce complex, high-precision parts across industries that were previously limited to more expensive processes. The result is a casting method that now combines traditional versatility with cutting-edge material science.