How important is tooling maintenance in reducing long-term stamping costs?

Introduction

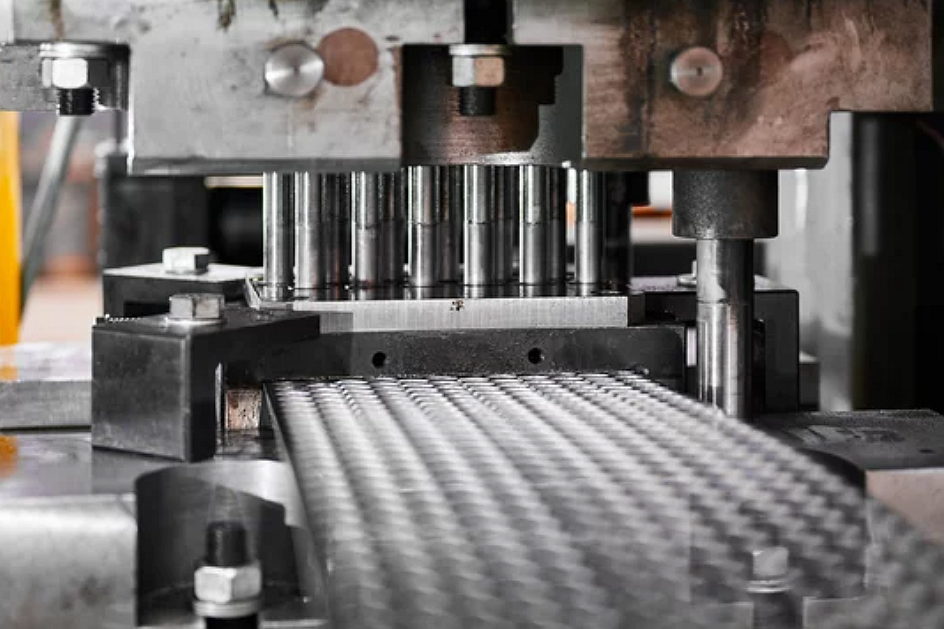

Tooling maintenance is one of the most influential factors in controlling long-term metal stamping costs. A well-maintained die ensures consistent forming accuracy, reduces scrap, minimizes downtime, and extends the usable life of the tooling investment. Because tooling is often the single largest upfront cost in a stamping program, the efficiency with which it is maintained directly shapes overall production economics. Upstream fabrication operations, such as sheet metal fabrication and high-accuracy cutting methods like laser cutting, help reduce tool stress by preparing uniform blanks. Complementary forming processes, including metal bending and efficient sheet metal stamping, also benefit from well-maintained dies. Early prototyping helps validate geometries and reduce future tooling strain.

Why Tooling Maintenance Is Critical for Cost Control

Extending Die Life

Tooling is engineered to withstand high forces, but without routine maintenance, wear accumulates rapidly. Micro-cracks, chipped cutting edges, and worn radii cause dimensional drift or part defects. Using harder alloys, such as stainless steel, or spring-back-prone materials like carbon steel, accelerates wear. Metals such as copper alloy deform easily but still require die surface conditioning to maintain accuracy. Lightweight, softer materials, including cast aluminum and corrosion-resistant zinc alloy, reduce wear but still demand stable lubrication and alignment.

Consistent maintenance helps avoid premature replacement, protecting the tooling investment.

Reducing Scrap and Improving Dimensional Stability

Worn dies produce inconsistent parts that fail dimensional checks or require rework. Scrap is one of the largest hidden costs in stamping—especially in high-value alloys or high-volume applications. Industries such as automotive require extremely tight tolerances, making tool condition crucial. Telecommunication applications rely on stamped metal for electrical accuracy, and even minor variations can lead to functional failure. Consumer electronics also rely on precise micro-features that degrade quickly without proper die upkeep.

Enhancing Press Efficiency and Reducing Downtime

Tool damage often leads to unplanned stoppages. Repairs during production halts elevate labor cost, disrupt delivery schedules, and reduce press utilization. A structured maintenance schedule minimizes downtime and keeps cycle times predictable.

Supporting High-Quality Finishing

Poorly maintained tools generate burrs, scratches, and surface defects, increasing reliance on downstream finishing operations. If post-processes such as anodizing or protective powder coating are required, maintaining smooth forming surfaces reduces secondary processing time and improves cosmetic quality.

Conclusion

Tooling maintenance is not simply an operational task—it is a strategic cost-control mechanism. Properly maintained dies extend service life, stabilize part quality, protect expensive materials from waste, and prevent costly downtime. For manufacturers seeking to optimize long-term production efficiency, tooling maintenance is one of the most crucial investments they can make.