What Complex Geometries Can Ceramic Injection Molding Parts Achieve?

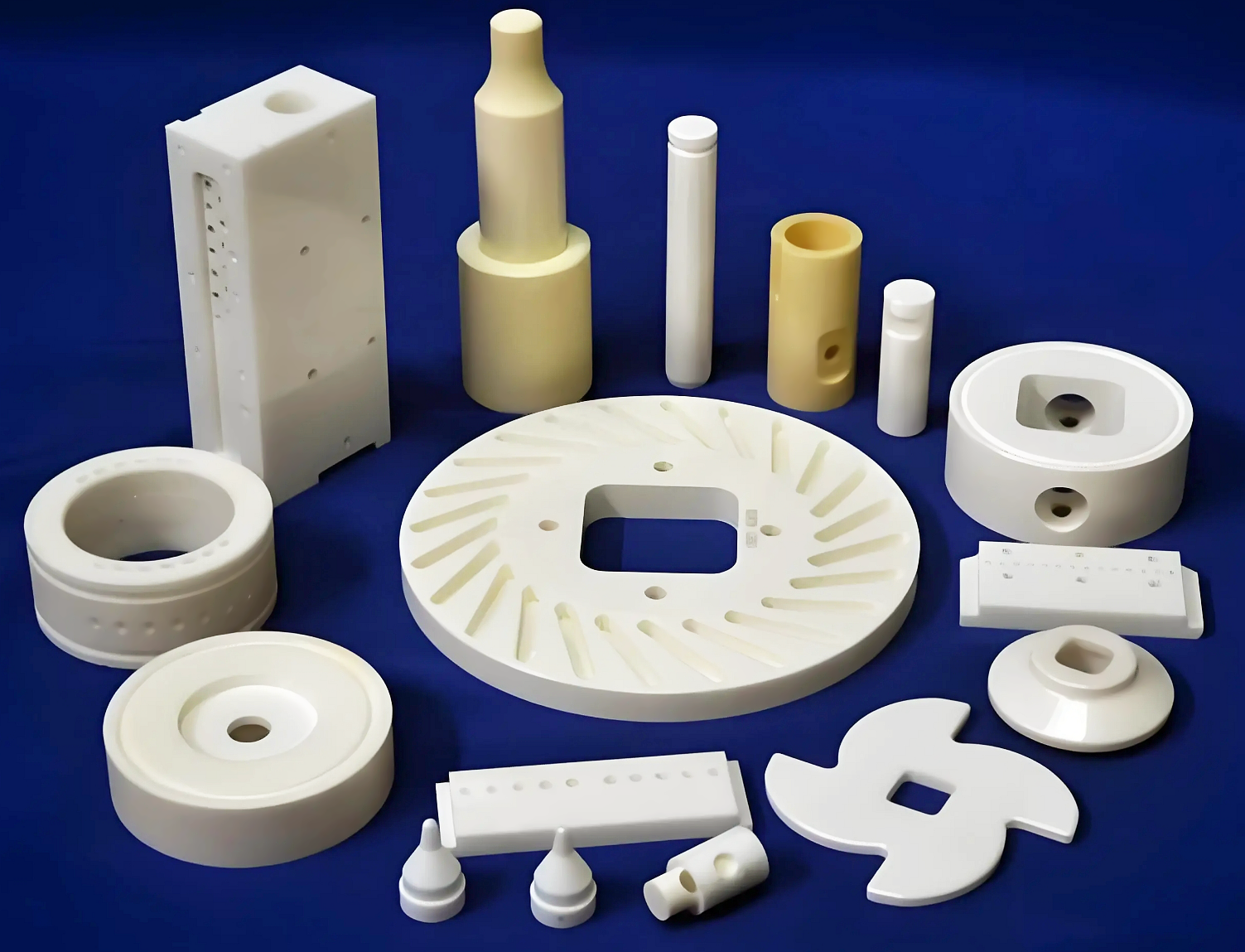

Ceramic Injection Molding (CIM) offers unmatched precision in manufacturing intricate ceramic parts. This advanced technique allows engineers and manufacturers to develop components with geometries that are difficult or impossible to achieve through traditional methods. This post explores the complex shapes that can be achieved with CIM, enabling industries to leverage ceramic manufacturing for exceptional performance.

Ceramic Injection Molding (CIM) offers unmatched precision in manufacturing intricate ceramic parts. This advanced technique allows engineers and manufacturers to develop components with geometries that are difficult or impossible to achieve through traditional methods. This post explores the complex shapes that can be achieved with CIM, enabling industries to leverage ceramic manufacturing for exceptional performance.

Understanding Ceramic Injection Molding (CIM)

Ceramic Injection Molding is an innovative manufacturing process that involves mixing ceramic powders with binders, molding under pressure, removing the binders (debinding), and sintering the component to achieve the final, high-density part. CIM combines the best attributes of injection molding and powder metallurgy, making it ideal for the mass production of highly complex ceramic parts and setting it apart from traditional manufacturing techniques, such as ceramic hot pressing molding.

Intricate Internal Channels and Fine Detail

Complex internal channels and fine details that are difficult or impossible to achieve through traditional ceramic forming processes are achievable with CIM. Industries such as medical, automotive, and aerospace frequently utilize CIM's capability to produce intricate internal channels and microstructures. Advanced applications of Ceramic Injection Molding in various industries vividly showcase these capabilities.

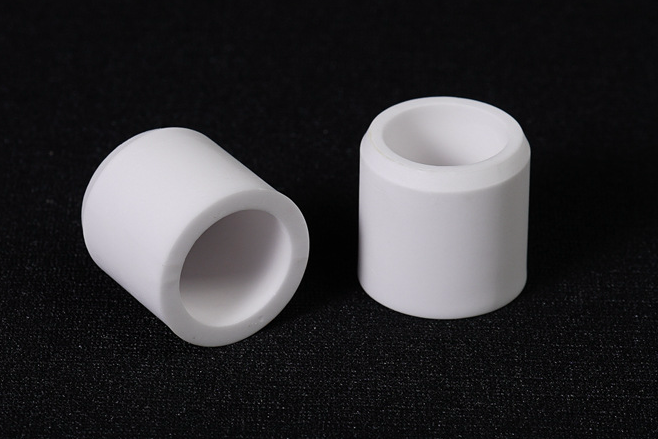

Thin-Walled and High Aspect Ratio Structures

CIM excels in manufacturing thin-walled and high-aspect-ratio ceramic parts. Thin ceramic walls, widely used in electronics and microfluidics, provide lightweight yet robust solutions. For instance, electronic components and microfluidic devices frequently benefit from CIM’s precise fabrication capabilities. Detailed insights on Alumina (Al2O3) Ceramic Injection Molding demonstrate the significance of these features.

Threads and Undercuts

Precision threads and undercuts, challenging for conventional ceramic processes, are achievable with CIM due to its flexibility and molding accuracy. Products like ceramic fasteners or specialized connectors significantly benefit from this precision, improving functionality and assembly reliability. The advantages and applications of ceramic injection molding illustrate why this technology is chosen for complex detailing.

Complex Surface Textures and Patterns

CIM uniquely enables the creation of intricate surface textures and patterns directly in molded ceramic components. These patterns can be both functional, improving grip or heat transfer, and aesthetic, enhancing product design. The diversity of ceramic materials and applications through injection molding further amplifies these benefits.

Factors Affecting Geometry Achievement

Several critical factors influence CIM’s success in achieving complex geometries, including:

Material Selection: Ceramic powders such as Zirconia (ZrO2) and Silicon Carbide (SiC) affect precision and shrinkage behavior.

Mold Design: The complexity and precision of the mold directly impact the accuracy of the final component.

Process Control: Injection parameters, such as pressure and temperature, and the accuracy of the sintering cycle, define the final tolerances and part properties.

These factors underscore the importance of precise process control for achieving optimal geometric outcomes in Ceramic Injection Molding.

Real-World Applications

CIM parts find significant use in various industries:

Medical Applications

CIM-produced ceramics are ideal for medical implants and surgical instruments thanks to their biocompatibility and precision. Complex dental implants and bio-compatible Zirconia components are examples of CIM's critical role in healthcare innovation.

Aerospace and Automotive

High-performance ceramic components produced by CIM are utilized extensively in the aerospace industry for their thermal and corrosion resistance, which is crucial in engine and sensor applications. Similarly, automotive sensor housings benefit significantly from the precise geometry that can be achieved through CIM.

Electronics

CIM produces highly precise insulating substrates and complex-shaped casings critical for device performance and reliability in electronics. Explore advanced ceramics injection molding services for more on electronic applications.

Challenges and Solutions

Despite CIM's advantages, achieving complex geometries presents some challenges, including shrinkage during sintering, high tooling costs, and fragile components in their unsintered (green) state. Manufacturers can overcome these issues through careful mold design, precise control of sintering conditions, and robust handling practices. Understanding the comprehensive ceramic injection molding process enables effective addressing of these challenges.

Maximizing CIM Capabilities Through Design

To fully utilize CIM's capabilities, designers should:

Engage manufacturers early in the design phase to understand process limitations and capabilities.

Optimize geometries to account for shrinkage and deformation during sintering.

Utilize simulation software to anticipate manufacturing challenges, enhance product quality, and reduce development cycles.

Such best practices are essential to the successful implementation of CIM.

Future Innovations

The future of CIM is promising, particularly with the integration of additive manufacturing techniques like 3D printing. These innovations will further expand the geometric capabilities, allowing for even greater design freedom and precision. 3D Printing's role in manufacturing provides insights into future manufacturing integration.

Conclusion

Ceramic Injection Molding empowers designers and manufacturers to create complex ceramic components with remarkable precision. Industries can maximize CIM's innovative potential by understanding the achievable geometries, leveraging precise design practices, and addressing process challenges. Embracing this technology positions industries at the forefront of ceramic manufacturing advancements, enabling new applications and breakthroughs.