How cost-effective is sheet metal stamping compared to other fabrication methods?

How Cost-Effective Is Sheet Metal Stamping Compared to Other Fabrication Methods?

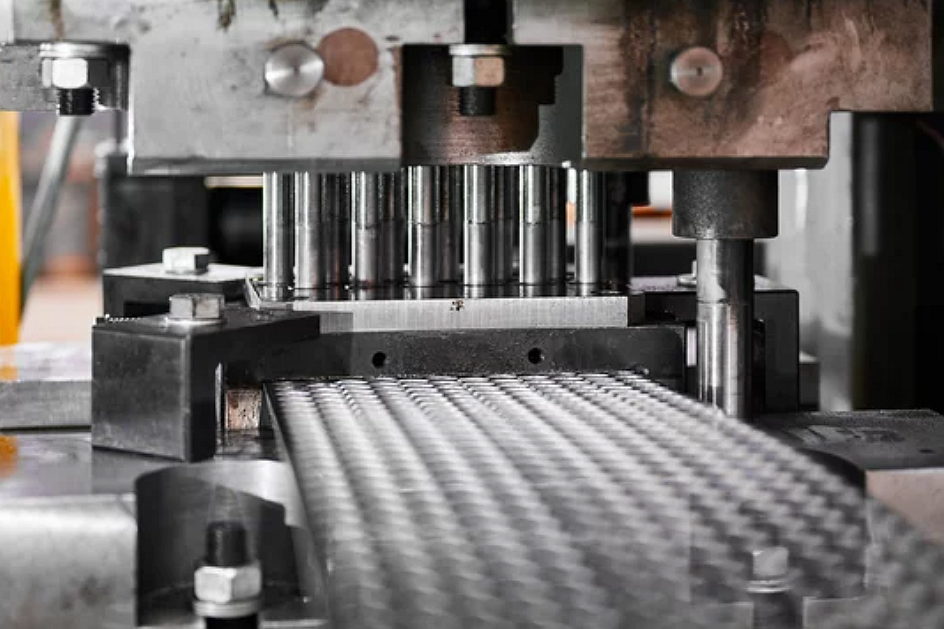

Sheet Metal Stamping: A High-Efficiency Mass Production Method

Sheet metal stamping offers significant cost advantages when producing high volumes of metal components. Once stamping dies are developed—typically requiring an upfront investment of $5,000–$50,000, depending on part complexity—per-part costs can drop to under $0.50 for simple geometries. The high-speed cycle times (up to 1,000 strokes per minute in progressive stamping) dramatically reduce labor and machine time compared to CNC machining, welding, or additive manufacturing.

Comparative Cost Metrics by Fabrication Method

Fabrication Method | Ideal Volume Range | Avg. Setup Cost | Avg. Unit Cost (Low-Mid Volume) | Efficiency Notes |

|---|---|---|---|---|

High (10,000+) | High (Tooling) | Very Low ($0.3–$1.5) | Best for scalable production | |

Low–Medium | Low–Medium | High ($5–$50) | High accuracy, low setup | |

Low–Medium | Low | Medium ($2–$10) | Good for prototyping | |

Medium–High | Very High (Tooling) | Low ($1–$5) | Excellent for complex small parts | |

Prototyping–Low | None–Low | Very High ($15–$100+) | Ideal for complex geometry, slow speed |

Sheet metal stamping becomes exponentially more cost-effective at higher volumes due to amortization of tooling and automation. For example, automotive OEMs save 20–30% in unit cost using progressive stamping vs. CNC machining for structural brackets, according to a 2023 PwC manufacturing cost study.

Operational Cost Advantages

Material Utilization: Up to 85–95% yield with optimized nesting, especially using carbon steel and stainless steel.

Labor Efficiency: One operator can oversee multiple press lines.

Speed: Cycle times as low as 0.06 seconds per part.

Consistency: Low reject rates (<2%) with automated stamping systems.

When Other Methods Make More Sense

For low-volume production, prototyping, or parts with complex internal geometries, processes like laser cutting, 3D printing, or CNC machining are often more economical due to minimal setup and no tooling investment.

Supporting Fabrication Services for Optimized Cost and Quality

To maximize ROI, Neway offers end-to-end support, including:

Sheet Metal Fabrication for high-volume production

CNC Machining for finishing stamped parts

Prototyping Services to evaluate design-for-manufacturing (DFM) upfront

Materials Library for selecting appropriate alloys and metals tailored to cost and performance

With 20+ years of experience, ±0.01mm accuracy, and global supply capabilities, we help you balance cost, precision, and scalability.