PBT

PBT (Polybutylene Terephthalate) Injection Molding Service

What Is Polybutylene Terephthalate (PBT)?

Polybutylene Terephthalate (PBT) is a high-performance thermoplastic polymer. It combines good heat resistance, dimensional stability, and low moisture absorption, making it a preferred material for manufacturing automotive parts, electrical connectors, and various consumer and industrial components.

Common grades of PBT used for injection molding at Neway include:

PBT 1000

PBT 2000

PBT 3000

PBT 4000

PBT 5000

Injection Molding PBT Grades Comparison

Comparing various PBT grades for injection molding, Neway offers a range of benefits. PBT grades vary in mechanical properties, heat resistance, and electrical insulation, making them suitable for diverse applications in industries like automotive, electronics, and consumer goods. These grades can be tailored to specific requirements, ensuring high-quality, durable parts for various applications.

Key Features And Applications

Grade | Key Features | Applications |

|---|---|---|

PBT 1000 | High strength and rigidity, good electrical properties, chemical resistance | Electrical connectors, automotive components |

PBT 2000 | Improved impact resistance, good dimensional stability, low moisture absorption | Automotive under-the-hood parts, electrical housings |

PBT 3000 | Excellent heat resistance, high creep resistance, low friction and wear | Gears, bearings, bushings, and pump components |

PBT 4000 | Enhanced flame resistance, good flowability, low outgassing | Electrical switches, connectors, and sockets |

PBT 5000 | High stiffness, good chemical resistance, low water absorption | Circuit breakers, lighting components |

Injection Molded PBT Typical Properties

Property | Density (g/cm³) | Tensile Strength (MPa) | Tensile Elongation (%) | Flexural Modulus (GPa) | Flexural Strength (MPa) | Izod Impact Strength (J/m) | Heat Deflection Temperature (°C) | Shrinkage (%) | Hardness (Rockwell R) |

|---|---|---|---|---|---|---|---|---|---|

PBT 1000 | 1.31 | 65 | 50 | 2.5 | 100 | 80 | 90 | 0.3 | 80 |

PBT 2000 | 1.32 | 70 | 60 | 2.8 | 110 | 90 | 100 | 0.2 | 85 |

PBT 3000 | 1.33 | 75 | 70 | 3.0 | 120 | 100 | 110 | 0.4 | 90 |

PBT 4000 | 1.34 | 80 | 80 | 3.2 | 130 | 110 | 120 | 0.5 | 95 |

PBT 5000 | 1.35 | 85 | 90 | 3.5 | 140 | 120 | 130 | 0.6 | 100 |

Benefits of Neway PBT Grades

PBT 1000

High Tensile Strength: PBT 1000 offers a solid tensile strength of 65 MPa, making it suitable for parts requiring robust mechanical properties.

Excellent Heat Resistance: With a heat deflection temperature of 90°C, it performs well in applications exposed to elevated temperatures.

Electrical Insulation: Its electrical insulating properties are ideal for electrical connectors, switches, and components.

PBT 2000

Enhanced Tensile Elongation: PBT 2000 boasts a tensile elongation of 60%, providing flexibility and toughness.

Improved Izod Impact Strength: This grade offers an Izod impact strength of 90 J/m, making it suitable for impact-resistant parts.

Automotive Components: It is commonly used in automotive components like bumpers, grille parts, and interior trim due to its impact resistance.

PBT 3000:

Higher Flexural Strength: PBT 3000 exhibits a flexural strength of 120 MPa, making it suitable for structural components.

Superior Heat Deflection: With a temperature of 110°C, it performs well in applications where heat resistance is crucial.

Precision Gears: Its strength and heat resistance combination makes it a preferred choice for precision gears and bearings.

PBT 4000:

Excellent Tensile Elongation: PBT 4000 offers a tensile elongation of 80%, providing strength and flexibility.

Increased Hardness: With a hardness of 95 Rockwell R, it's well-suited for parts requiring hardness and toughness.

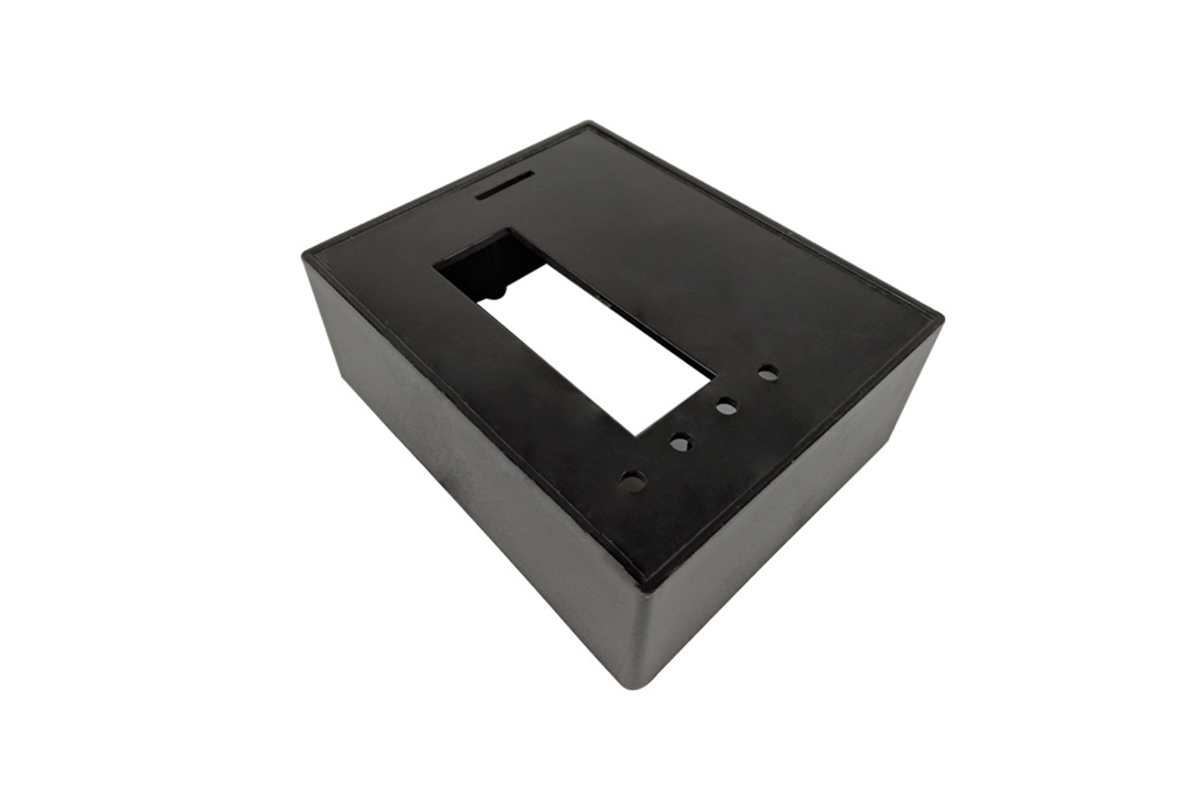

Electrical Housings: Its balance of properties makes it suitable for electrical housings and enclosures in various industries.

PBT 5000:

High Tensile Strength: PBT 5000 boasts a tensile strength of 85 MPa, ensuring durability in demanding applications.

Superior Chemical Resistance: It resists chemicals, making it a good choice for parts exposed to corrosive environments.

Medical Devices: PBT 5000 is commonly used in medical device components due to its chemical resistance and strength.

What We Can Offer?

Neway offers a variety of injection molding process options, including:

1. Plastic Injection Molding Service

4. Multi Shoot Injection Molding Service

And various standard and custom materials for injection molding, including:

Thermoplastics | Thermosets | |||

Medical-Grade silicone rubber | ||||

Optical silicone rubber | ||||