POM

POM (Acetal/Delrin) Injection Molding Manufacturing

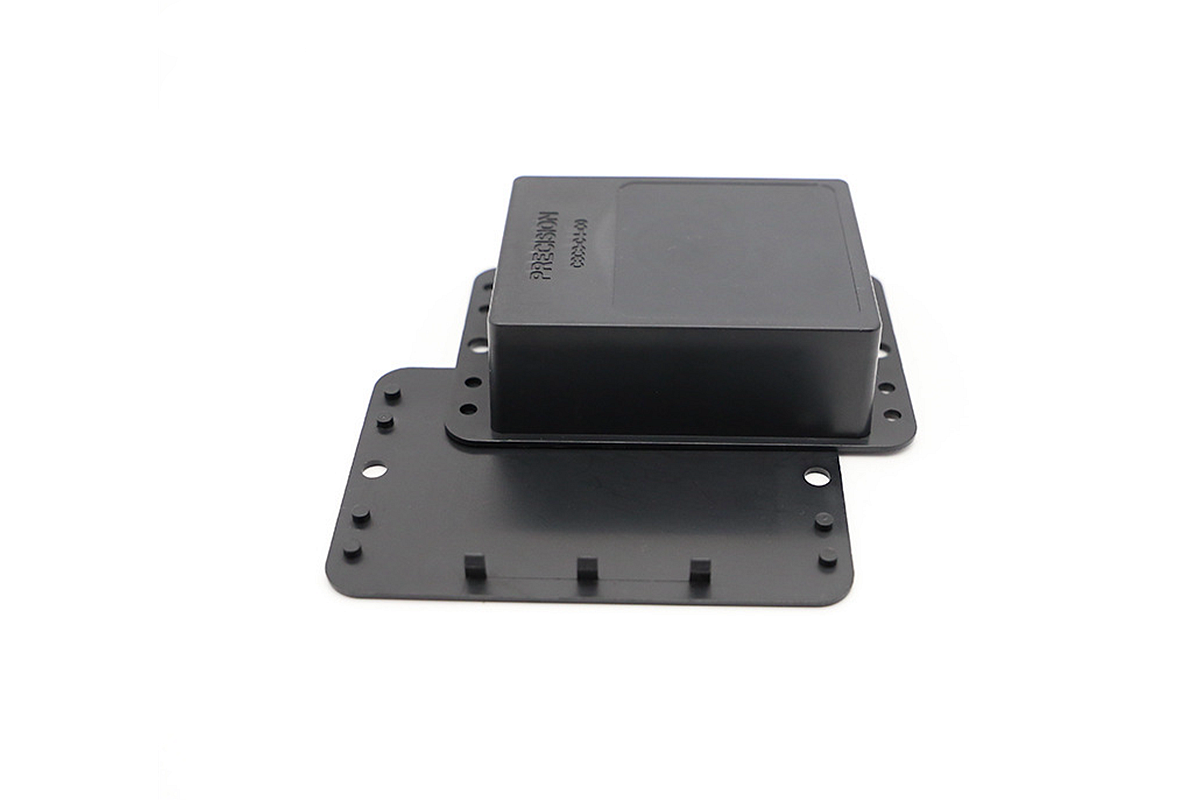

Overview of Injection Molded POM

Injection-molded POM grades differ in properties. Delrin® offers general versatility, Delrin® AF combines POM with PTFE for reduced friction, Delrin® 570 is FDA-compliant, Hostaform® emphasizes engineering properties, and Celcon® specializes in low-friction applications, catering to various industrial needs.

Neway utilizes various grades of injection molded POM (Polyoxymethylene), including:

Delrin® (General-Purpose POM)

Delrin® AF (Filled POM with PTFE)

Delrin® 570 (FDA-Compliant POM)

Hostaform® (Engineering POM)

Celcon® (Low-Friction POM)

Injection Molded POM Grades Comparison

Comparing injection molded POM grades allows for precise material selection. Delrin® offers versatility, Delrin® AF reduces friction, Delrin® 570 ensures FDA compliance, Hostaform® caters to engineering needs, and Celcon® addresses low-friction applications, optimizing performance for specific plastic injection molding parts.

Key Features And Applications

POM Grade | Key Properties | Applications |

|---|---|---|

Delrin® | - Versatility - High stiffness - Excellent dimensional stability | Gears, bushings, fasteners, automotive components |

Delrin® AF | - Low friction - Wear resistance - PTFE-filled | Bearings, bushings, conveyor systems, moving parts |

Delrin® 570 | - FDA-compliant - Good chemical resistance | Food processing equipment, medical devices, conveyor belts |

Hostaform® | - Engineering properties - High strength | Automotive parts, precision gears, electrical components |

Celcon® | - Low friction - High wear resistance | Low-friction bearings, conveyor components, pump parts |

Physical And Mechanical Properties of Injection Molded POM

Property | Density (g/cm³) | Tensile Strength (MPa) | Tensile Elongation (%) | Flexural Modulus (GPa) | Flexural Strength (MPa) | Izod Impact Strength (J/m) | Heat Deflection Temp. (°C) | Shrinkage (%) | Hardness (HRB) |

|---|---|---|---|---|---|---|---|---|---|

Delrin® | 1.42 | 85 | 50 | 3.2 | 135 | 105 | 150 | 2.5 | 120 |

Delrin® AF | 1.47 | 78 | 20 | 3.1 | 125 | 43 | 130 | 2.0 | 110 |

Delrin® 570 | 1.41 | 75 | 60 | 2.8 | 103 | 80 | 90 | 3.0 | 110 |

Hostaform® | 1.42 | 75 | 50 | 3.2 | 128 | 160 | 120 | 2.5 | 120 |

Celcon® | 1.42 | 77 | 50 | 3.2 | 124 | 83 | 120 | 3.0 | 120 |

POM Grades Injection Molding Properties And Applications

Delrin® (General-Purpose POM)

Delrin® is a versatile general-purpose POM known for its high stiffness, excellent dimensional stability, and ease of machining. With a 1.42 g/cm³ density, it boasts a tensile strength of up to 85 MPa and a flexural modulus of 3.2 GPa. This makes it ideal for gears, bushings, fasteners, and various automotive components. Its resistance to wear, chemicals, and moisture ensures durable performance.

Delrin® AF (Filled POM with PTFE)

Delrin® AF combines POM with PTFE to create a low-friction material that offers wear resistance and a coefficient of friction as low as 0.12. With a density of 1.47 g/cm³, it maintains a tensile strength of up to 78 MPa and a flexural modulus of 3.1 GPa. Bearings, bushings, conveyor systems, and moving parts benefit from reduced friction.

Delrin® 570 (FDA-Compliant POM)

Delrin® 570 is an FDA-compliant POM with a 1.41 g/cm³ density. It offers a tensile strength of up to 75 MPa and a flexural modulus of 2.8 GPa. Its suitability for food processing equipment, medical devices, and conveyor belts arises from its good chemical resistance and compliance with stringent FDA regulations.

Hostaform® (Engineering POM)

Hostaform® is an engineering-grade POM valued for its high strength, even at elevated temperatures. With a density of 1.42 g/cm³, it boasts a tensile strength of up to 75 MPa and a flexural modulus of 3.2 GPa. Automotive parts, precision gears, and electrical components benefit from their exceptional mechanical properties, including resistance to wear and fatigue.

Celcon® (Low-Friction POM)

Celcon® is a low-friction POM designed for applications requiring minimal wear and reduced friction. With a 1.42 g/cm³ density, it maintains a tensile strength of up to 77 MPa and a flexural modulus of 3.2 GPa. Its unique combination of low friction, high wear resistance, and dimensional stability makes it ideal for low-friction bearings, conveyor components, and pump parts.

Try Design, Quotation, and Prototyping Works For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.

Thermoplastics | Thermosets | |||

Medical-Grade silicone rubber | ||||

Optical silicone rubber | ||||