PPS

PPS (Polyphenylene Sulfide) Injection Molding Supplier

Overview of Injection Molded PPS

Injection-molded PPS (Polyphenylene Sulfide) is a high-performance thermoplastic known for its outstanding heat resistance, chemical inertness, electrical insulating properties, and mechanical strength. It is widely used in industries requiring durable and heat-resistant components.

Neway utilizes various grades of injection molded PPS (Polyphenylene Sulfide), including:

General-Purpose PPS

Reinforced PPS

Flame-Retardant PPS

Conductive PPS

Glass-Filled PPS

Injection Molded PPS Grades Comparison

Injection-molded PPS grades vary in properties. General-purpose PPS offers high heat resistance and chemical inertness, ideal for automotive parts and electrical components. Reinforced PPS adds strength for structural uses. Flame-retardant PPS suits electronics. Conductive PPS is used for ESD protection, and glass-filled PPS enhances the mechanical strength of industrial components. PPS injection molding parts find applications in automotive, electronics, aerospace, and industrial equipment due to their exceptional heat resistance, chemical resistance, and mechanical properties.

PPS Key Features And Applications

PPS Grade | Key Properties | Common Applications |

|---|---|---|

General-Purpose PPS | - Exceptional heat resistance - Chemical inertness - High electrical resistance | Automotive parts, electrical components |

Reinforced PPS | - Enhanced mechanical strength - Improved dimensional stability - Good chemical resistance | Structural components, industrial equipment |

Flame-Retardant PPS | - Flame resistance - Low smoke emissions - Good electrical properties | Electronics, aircraft interiors, electrical enclosures |

Conductive PPS | - Electrical conductivity - Electrostatic discharge (ESD) protection - Chemical resistance | Electronic packaging, ESD-sensitive applications |

Glass-Filled PPS | - Increased stiffness and strength - Dimensional stability - Chemical resistance | Industrial machinery, automotive, structural parts |

Physical And Mechanical Properties of Injection Molded PPS

Property | Density (g/cm³) | Tensile Strength (MPa) | Tensile Elongation (%) | Flexural Modulus (GPa) | Flexural Strength (MPa) | Izod Impact Strength (J/m) | Heat Deflection Temp. (°C) | Shrinkage (%) | Hardness (HRB) |

|---|---|---|---|---|---|---|---|---|---|

General-Purpose PPS | 1.30 | 75 | 2 | 3.0 | 150 | 50 | 95 | 0.3 | 85 |

Reinforced PPS | 1.50 | 110 | 1.5 | 4.0 | 180 | 30 | 220 | 0.5 | 90 |

Flame-Retardant PPS | 1.45 | 85 | 1.8 | 3.5 | 160 | 40 | 180 | 0.4 | 88 |

Conductive PPS | 1.40 | 95 | 2.0 | 3.2 | 170 | 35 | 160 | 0.4 | 87 |

Glass-Filled PPS | 1.80 | 150 | 1.0 | 6.0 | 250 | 15 | 260 | 0.7 | 95 |

PPS Grades Injection Molding Properties And Applications

General-Purpose PPS

Key Properties: General-purpose PPS is characterized by its excellent heat resistance, with a heat deflection temperature of approximately 95°C. It has good chemical inertness and high electrical resistance. Its tensile strength is around 75 MPa and exhibits moderate impact strength.

Applications: This grade of PPS finds applications in various industries, including automotive and electrical. Typical uses include automotive parts exposed to high temperatures, electrical connectors, and insulating components.

Reinforced PPS

Key Properties: Reinforced PPS offers enhanced mechanical properties. It has a higher tensile strength of about 110 MPa and improved dimensional stability. The heat deflection temperature is elevated, typically reaching around 220°C. This grade has good chemical resistance.

Applications: Reinforced PPS is preferred for applications where strength and dimensional stability are crucial. It is used in structural components, industrial equipment, and parts that must withstand high-temperature environments.

Flame-Retardant PPS

Key Properties: Flame-retardant PPS is designed to resist combustion and emit low levels of smoke. It maintains good electrical properties and has a tensile strength of approximately 85 MPa. Its heat deflection temperature is around 180°C.

Applications: This grade is ideal for applications where fire safety is paramount, such as electronics, aircraft interiors, and electrical enclosures, ensuring that components meet stringent fire safety standards.

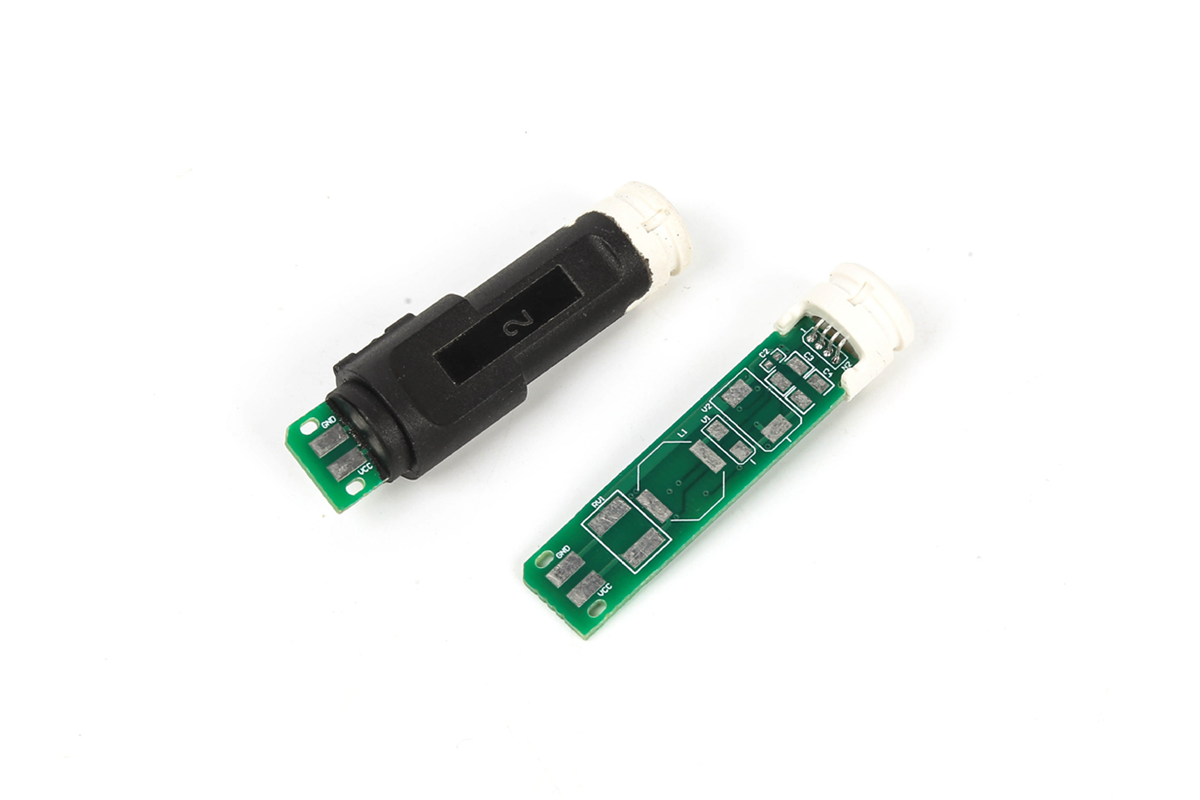

Conductive PPS

Key Properties: Conductive PPS possesses electrical conductivity, making it suitable for electrostatic discharge (ESD) protection applications. It offers good chemical resistance, a tensile strength of about 95 MPa, and a heat deflection temperature of approximately 160°C.

Applications: Conductive PPS is used in electronic packaging, where ESD protection is vital. It prevents damage to sensitive electronic components and is employed in various ESD-sensitive applications.

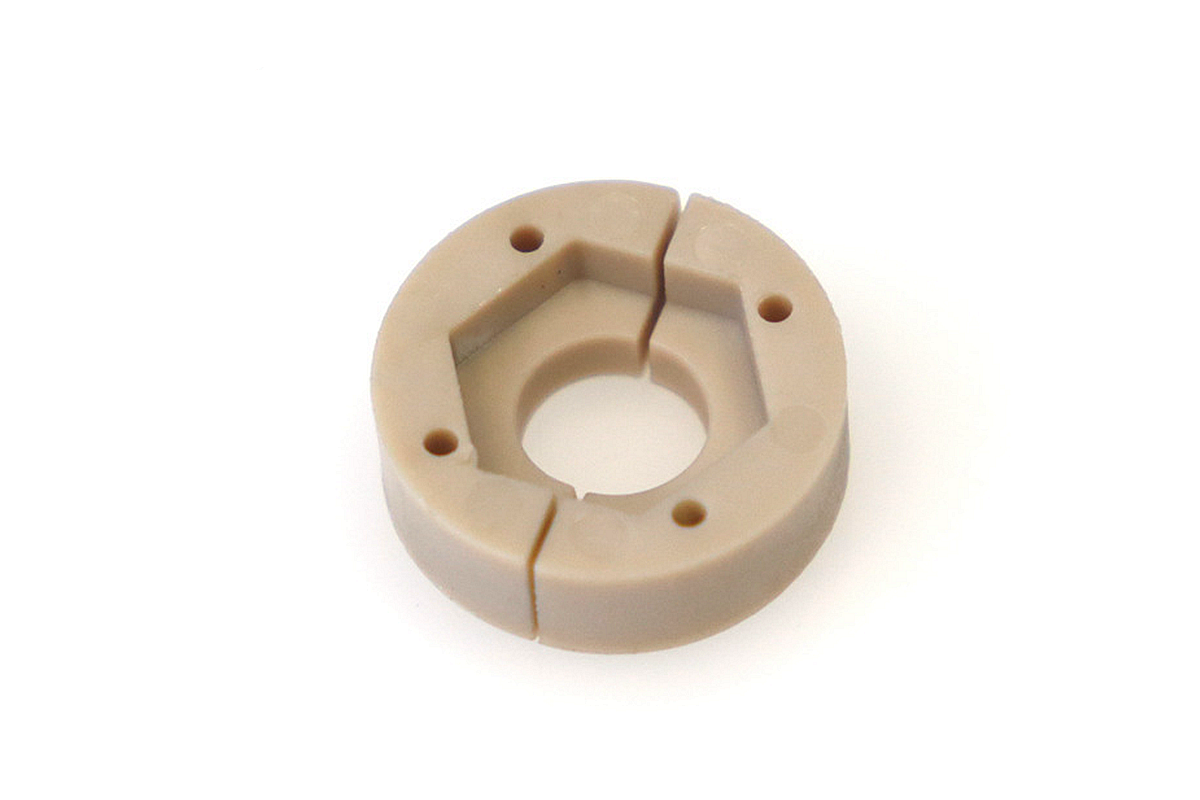

Glass-Filled PPS

Key Properties: Glass-filled PPS is reinforced with glass fibers, increasing stiffness and strength. It has a high tensile strength of around 150 MPa and a heat deflection temperature reaching 260°C. It exhibits lower shrinkage.

Applications: This grade excels in industrial machinery, automotive components, and structural parts that demand enhanced mechanical properties. Its dimensional stability and resistance to wear make it suitable for high-stress applications.

What We Can Do In Plastic Injection Molding?

We can provide a one-stop service from prototyping to mass production for your custom injection molded parts. this includes

2. Mechanical Design Service

4. On-Demand Manufacturing Service

5. Simple Assembly Service

Thermoplastics | Thermosets | |||

Medical-Grade silicone rubber | ||||

Optical silicone rubber | ||||