What are the limitations of 3D printing in industrial applications?

What Are the Limitations of 3D Printing in Industrial Applications?

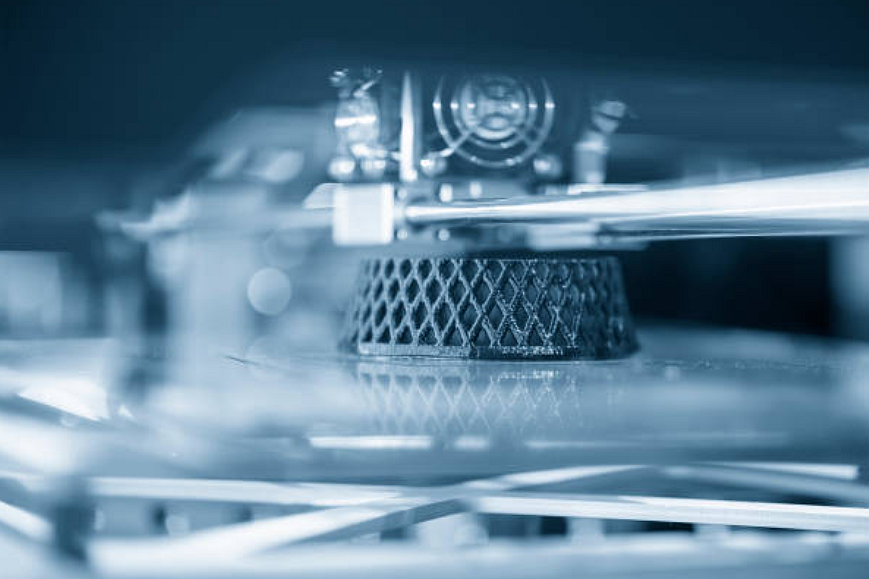

Understanding the Boundaries of Additive Manufacturing

While 3D printing offers unmatched flexibility for design complexity, low-volume production, and rapid prototyping, it still faces several constraints in industrial settings. These limitations—ranging from material properties to dimensional tolerances—affect its applicability for certain high-demand use cases when compared to traditional manufacturing methods.

1. Material Limitations

Although the range of printable materials continues to grow, it still lags behind conventional processes:

Limited availability of high-strength alloys like tool steels and superalloys in consistent, printable forms.

Most printable polymers (e.g., ABS, [PLA], PETG) lack the mechanical durability and thermal resistance required for structural load-bearing applications.

2. Surface Finish and Post-Processing

3D printed parts often require secondary processes to meet functional or aesthetic standards:

Surface roughness for SLS or DMLS parts can exceed Ra 10–20 μm, which is unacceptable for sealing surfaces or sliding contacts.

Post-processing such as CNC finishing, polishing, or heat treatment adds time and cost.

3. Dimensional Accuracy and Tolerances

While high-end machines can achieve ±0.05 mm tolerances, additive processes generally fall short of the ±0.01 mm precision typical in CNC machining:

Thermal distortion, warping, and shrinkage—especially in large prints—can affect dimensional stability.

Precision fits may require secondary machining or design adjustments.

4. Production Speed and Scalability

3D printing is not yet competitive for high-volume manufacturing:

Most industrial machines build parts layer-by-layer, making large batch runs time-consuming.

Injection molding or die casting can produce thousands of parts in the time it takes to print dozens.

5. Structural Anisotropy

Parts built through additive processes, particularly FDM or SLA, exhibit directional mechanical properties:

Layer adhesion is often weaker than intra-layer strength, resulting in anisotropic behavior under stress.

This makes them unsuitable for critical loads unless printing orientation and material are carefully selected.

6. Equipment and Operational Costs

While the per-unit cost is low at small volumes, industrial 3D printing equipment (especially DMLS or SLM) involves high capital and maintenance expenses:

Metal printers can exceed $500,000 in setup cost.

Powder handling, atmosphere control, and operator training are required for safe, consistent output.

Supporting Hybrid Manufacturing Solutions

Neway mitigates 3D printing limitations by offering:

Combined 3D Printing + CNC Finishing for dimensional accuracy

Material Selection Services to align properties with application demands

Prototyping and Bridge Manufacturing to transition from design to scaled production

With ±0.01 mm post-machining precision, industry-grade materials, and global delivery, Neway ensures your additive manufacturing projects overcome key industrial barriers.