How are future innovations enhancing the sustainability of sand casting?

Advanced Sand Reclamation Technologies

Next-generation sand casting facilities are adopting high-efficiency sand reclamation systems that enable nearly complete recycling of molding materials. Mechanical, thermal, and wet reclamation methods remove binders, fines, and contaminants from used sand, restoring it for repeated cycles without quality degradation. This reduces virgin sand consumption by up to 95%, significantly lowering waste and energy costs while supporting circular manufacturing principles in the energy sector and automotive industry.

Bio-Based and Low-Emission Binder Systems

Traditional chemical binders are being replaced with eco-friendly alternatives made from biopolymers, starches, and lignin derivatives. These materials produce fewer volatile organic compounds (VOCs) during pouring and eliminate toxic residues in waste sand. Foundries implementing such sustainable binder technologies meet stricter environmental standards while maintaining casting strength and mold cohesion comparable to conventional bentonite systems.

Energy-Efficient Melting and Heat Recovery

Modern foundries now integrate induction furnaces and regenerative burners to improve melting efficiency. These systems recycle thermal energy from exhaust gases, reducing overall fuel consumption. When combined with intelligent heat treatment control, they enable consistent alloy properties while minimizing CO₂ emissions for materials such as cast aluminum and cast iron.

Digital Simulation and AI Optimization

The integration of digital twin and artificial intelligence tools allows precise modeling of mold filling, cooling, and solidification. This predictive control reduces defects, eliminates trial-and-error runs, and decreases the need for remelting scrap. AI-driven process tuning also optimizes sand composition, moisture content, and compaction levels, creating a closed-loop feedback system that maintains consistent casting quality with minimal resource use.

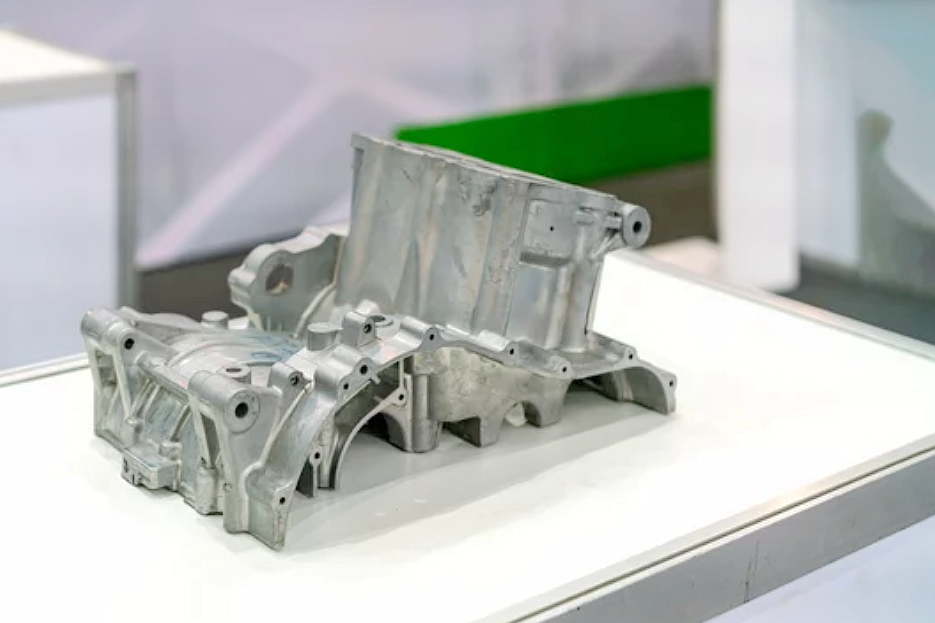

Additive Manufacturing for Mold and Core Production

Hybrid manufacturing, which combines 3D printing and prototyping with sand casting, is revolutionizing mold making. 3D-printed sand cores eliminate traditional tooling waste, reduce lead time, and improve design complexity without additional material loss. This technology enables more efficient production of complex geometries for aerospace and e-mobility applications, promoting sustainability through digital manufacturing flexibility.

Sustainable Surface Treatments and Coatings

Eco-friendly finishing techniques, including powder coating, anodizing, and PVD coating, have replaced solvent-based methods that generate hazardous waste. These coatings extend part lifespan and enhance corrosion resistance, reducing the frequency of replacement and conserving raw materials.

Smart Environmental Monitoring Systems

Modern foundries utilize IoT-based environmental sensors to monitor temperature, emissions, and dust levels in real-time. Data analytics allow for proactive control of air filtration and binder usage, ensuring compliance with ISO 14001 environmental management standards. This integration of smart monitoring enhances both worker safety and ecological performance.

Circular Economy Integration and Life-Cycle Design

Sustainability innovations in sand casting are increasingly focused on life-cycle assessment (LCA). Manufacturers now design castings for disassembly, reuse, and recycling at the end of product life. Combined with localized production and the adoption of renewable energy, these approaches close the resource loop and reinforce sand casting’s role in global sustainable manufacturing initiatives.