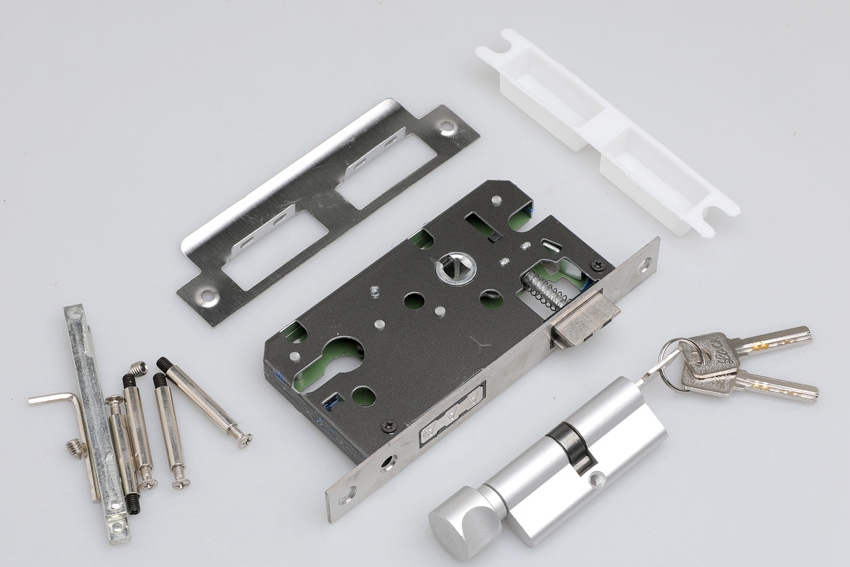

高精度ロック機構製造ソリューション

現代のセキュリティシステムにおいて、ロックの信頼性は製造時の内部機構の精度に直接依存します。ミクロンレベルの寸法偏差であっても、テクニカルな解錠手法に対する耐性低下、操作感の粗さ、さらには早期故障につながる可能性があります。Neway のエンジニアリングチームとして、私たちは「精度」と「セキュリティ」の本質的な結びつきを深く理解しています。先進的な製造技術と厳格な品質管理を通じて、世界中のロックメーカーに向けて信頼できる高精度ソリューションを提供します。すべての精密ロック部品にはセキュリティへのコミットメントが宿っており、その実現には製造卓越性を徹底的に追求し続ける姿勢が不可欠です。

ミクロンレベル精度を実現する中核製造技術

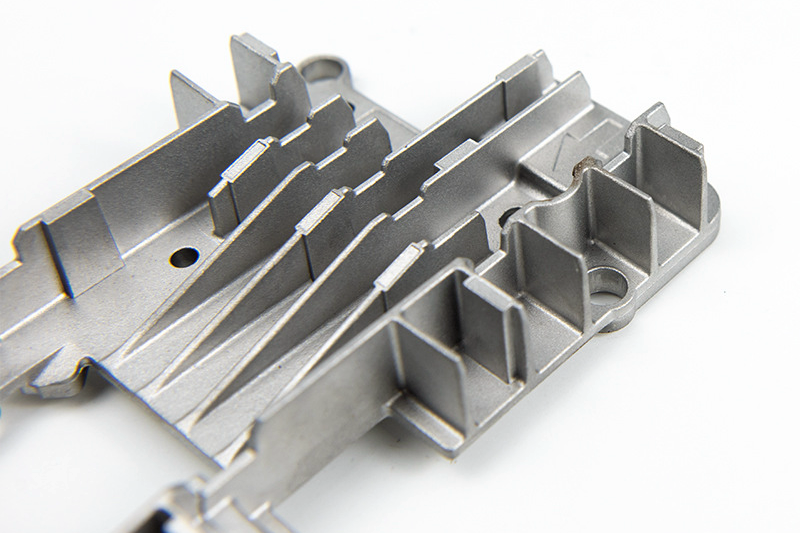

多軸精密 CNC 加工:複雑形状と極限公差を保証

多軸精密加工の分野において、CNC 試作加工は高精度ロック機構に対して比類のない能力を提供します。5軸加工センタは、複雑な輪郭の多面加工を1回の段取りで完了でき、ロックシリンダー、ウェハー、伝達部品間の最適な嵌合を確保します。当社の精密加工設備は、寸法公差 ±0.005mm、表面粗さは Ra0.4 まで達成可能です。この精度により、可動部は滑らかに作動しつつ、内部構造へのテクニカルな探り(プロービング)を効果的に抑制できます。高セキュリティロックに用いられる精密部品にとって、CNC 加工は代替不可能な精度保証となります。

金属射出成形(MIM):量産・複雑小型部品における精度と効率

複雑な微小部品の量産に直面する場合、金属射出成形(MIM)サービスは卓越した技術的優位性を示します。本プロセスは、複雑な三次元構造を持つロックピン、マイクロギア、ラチェットの製造に特に適しており、従来の機械加工では困難な形状を実現できます。MIM は成形公差を最大 ±0.3% まで実現でき、製品密度は 96% 以上、機械特性は鍛造部品に近いレベルです。大規模生産において、MIM は各部品の高い一貫性を確保し、ロックシステムにおける互換性と信頼性にとって極めて重要です。

精密プレス・成形:薄肉かつ高強度構造部品の高効率生産

ロック内部のばね、止め輪、接点板などの薄肉部品には、専用の製造プロセスが必要です。板金プレスは、精密金型と自動化設備を用いて、高精度な薄肉部品を高速で生産します。当社の多段順送金型は、毎分数百個の生産速度を実現しながら、寸法精度を ±0.05mm 以内に維持できます。精密プレス部品は優れた弾性と疲労強度を提供し、ロック機構が長期使用でも安定した性能を維持することを可能にします。

粉末圧縮成形(PCM):耐摩耗・特殊機能部品のソリューション

特殊な性能要件を持つロック部品に対して、粉末圧縮成形(PCM)サービスは独自のソリューションを提供します。PCM は気孔率を制御した部品を製造でき、微細孔に潤滑油を保持させて自己潤滑性能を実現し、可動部の摩耗を大幅に低減できます。材料配合を精密に制御することで、高耐摩耗性、特定の磁性、あるいは狙いを定めた電気特性を持つロック部品の製造が可能です。本プロセスは、ロック機構内で特殊特性が求められる軸受スリーブ、ガイド、その他機能要素に特に適しています。

性能と耐久性を保証する精密後処理技術

精密成形された部品は、最適性能を得るために専門的な後処理が必要です。熱処理プロセスは、加熱・冷却を制御して材料の結晶構造を調整し、ロック部品に必要な硬さ、強度、靭性を付与します。材料と用途に応じて、焼入れ、焼戻し、浸炭などを適用し、脆性破壊を防ぎつつ十分な硬度と適切な靭性を両立させます。超平滑な表面が求められる精密部品には、電解研磨により微細なバリを除去し、表面粗さを低減して可動部の摩擦と摩耗を抑えます。バレル研磨は小型部品のバッチ処理に適しており、穏やかにバリ取りしながら均一な表面光沢を形成します。

高精度ロック部品における主要材料選定

高寸法安定性ステンレス鋼および合金鋼

材料選定は、ロック部品の寸法安定性と寿命に直接影響します。ステンレス鋼は優れた耐食性と強度により、高精度ロックの第一選択となります。420 や 440C などのマルテンサイト系ステンレス鋼は、適切な熱処理により HRc 50〜55 の硬度を達成しつつ、十分な靭性を維持できます。さらに高い強度が必要な用途では、低合金鋼である 4140 や 4340 を焼入れ・焼戻しして、優れた機械特性を得られます。これら材料は高い寸法安定性を示し、長期使用にわたって精度を維持します。

耐摩耗性銅合金および特殊材料

低摩擦と高耐摩耗性が求められる用途には、銅合金が理想的なソリューションを提供します。青銅、黄銅などの銅系合金は自己潤滑的特性を持ち、摩擦係数を低減して可動部のかじりや固着を防ぎます。また、優れた熱伝導性と耐食性を備えており、ロックシリンダー、キーなど摩耗の大きい部位に特に適しています。銅合金は被削性にも優れるため、高精度ロック製造に求められる複雑形状と厳しい公差を実現できます。

高性能エンジニアリングプラスチックおよびセラミックス

材料科学の進歩により、低摩擦、高耐摩耗性、良好な寸法安定性を備えるPOMは、ロック製造において一部金属部品を置き換える例が増えています。このエンジニアリングプラスチックは、ギア、スライダー、ブッシュに適しており、作動音を低減しながら滑らかさを向上させます。極限の耐摩耗・耐食性が必要な特殊用途では、ジルコニアセラミック部品が従来材料を上回る性能を提供します。セラミックスの卓越した硬度と化学的不活性は、高セキュリティロック、とりわけ過酷環境での長期使用において理想的な選択肢となります。

各種ロックソリューションにおける高精度機構の適用

機械式ロックシリンダーおよびキーシステムの精密中核

機械式ロックの防犯性能は、精密機構の加工品質に完全に依存します。当社のロックシステムソリューションは、従来のピンタンブラー錠から高度なウェハー錠まで幅広く対応します。シリンダー内の各ピン穴、ウェハースロット、プロファイルは、適合するキーのみが滑らかに操作できるよう、ミクロンレベルの加工精度が必要です。精密に管理されたクリアランスは、振動やプロービングなどのテクニカルな開錠手法を抑制しつつ、上質な操作感を提供します。高セキュリティロックでは、専用の加工プロセスと公差管理を採用し、テクニカルアタックに対する最高レベルの耐性を実現します。

スマートロック/メカトロニクスロックの駆動機構

現代のスマートロックは、機械的精密性と電子制御を統合しており、駆動機構に対してさらに高い精度要求が課されます。モーター駆動ギアボックス、ねじ駆動機構、電磁クラッチなどの主要部品では、厳格な寸法管理と適切な材料選定が不可欠です。精密製造により、これら部品が 45 dB 未満の低騒音で動作し、100,000 サイクルを超える寿命を達成することを保証します。高精度の伝達機構はラッチの伸縮を正確に制御し、位置ずれに起因する不具合を防止します。スマートロックの機械—電子インターフェース部品には、長期安定性能を確保するための特別な精度配慮が必要です。

高セキュリティ特殊ロック向け精密構造

銀行金庫やセーフなどの高セキュリティ環境で使用される特殊ロックは、製造精度に対して極めて厳しい要求を課します。これらのロックは一般に、機械式の組合せ、電子認証、物理的保護など、多要素防護を統合しています。当社が供給する精密部品には、正確に位置決めされたダイヤル、0.01mm 以内の公差を持つロックボルト、特殊合金製の安全機構などが含まれます。すべての部品は 100% 寸法検査と機能試験を実施し、極限条件下でも確実に動作することを保証します。こうした特殊ロックの製造では複数プロセス技術の統合が求められるため、プロセス革新と厳格な品質管理により、重要用途の要求を満たします。

高精度ロック機構開発を成功させる4つのエンジニアリング支柱

高精度ロック機構の開発成功は、4つの主要なエンジニアリング支柱に基づきます。製造容易性設計(DFM)は、製品設計段階からプロセス実現性とコスト効率を考慮し、構造最適化によって製造難易度とコストを低減します。公差解析と嵌合設計は、組立後にすべての部品が意図通り機能することを保証し、統計的公差解析により製品歩留まりを予測します。材料とプロセスの協調選定では、性能要件、生産量、経済性を踏まえて最適解を特定します。エンドツーエンドの品質監視と計測は、先進的な検査設備と堅牢な品質システムによって各工程を管理下に置きます。これらの原則が一体となり、高精度ロック製品成功の強固な基盤を形成します。

結論:精密製造の専門家と協業し、完璧なセキュリティ性能を実現する

高精度ロック機構の製造は、複数の加工技術の統合適用と厳格な品質管理を要する体系的なエンジニアリング活動です。材料選定とプロセス定義から、加工、後処理、最終検証に至るまで、すべての段階で専門知識と豊富な経験が求められます。多材料成形と精密製造における技術優位性を活かし、Neway はコンセプト設計から量産まで、ロックメーカーに対して包括的なソリューションを提供します。私たちは技術革新と妥協なき品質にコミットし、お客様とともに、より安全で、より信頼性が高く、より耐久性に優れたロック製品を創出し、人々の生命と財産を守る堅牢な防護を実現します。