If a test fails, can Neway support quick redesign and re-prototyping?

Yes. When a test fails during validation, Neway can rapidly support redesign and re-prototyping by leveraging simulation feedback, agile process routing, and in-house prototyping capabilities. Our development workflow is designed to handle rapid iterations—especially for components used in automotive, e-mobility, and aerospace systems—where test results often drive geometric refinement, material upgrades, or process adjustments.

Simulation Feedback and Design Adjustment

Failed tests are treated as data-driven feedback. Strain, temperature, or deformation readings are fed back into digital models to update boundary conditions and optimize load paths. Using topology optimization and FEA tools, engineers can modify section geometry, local reinforcement, or heat dissipation features before proceeding to the next prototype iteration.

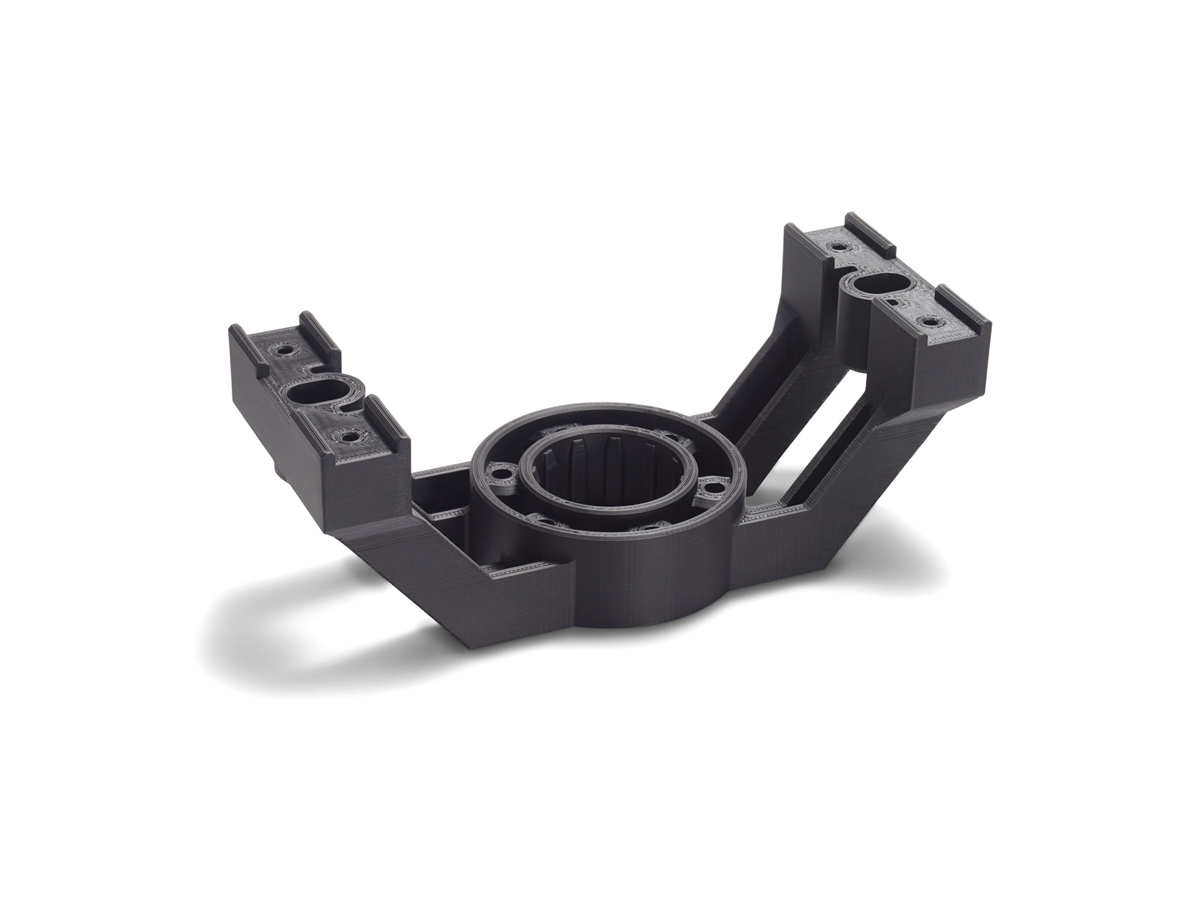

Once the design revision is ready, production-intent prototypes are quickly built using CNC machining prototyping or 3D printing prototyping. These methods enable rapid changes to geometry, including stiffening ribs, joining features, cooling channels, or tolerance-critical areas, without waiting for final tooling.

Process Flexibility for Fast Re-Prototyping

For cast or molded parts, Neway offers flexible routing between precision casting, aluminum die casting, injection molding, and sheet metal fabrication, depending on the required lead time and complexity. If the redesign is local—such as a single area reinforcement—prototype tooling or inserts can be modified rather than replaced entirely, saving significant time.

Compact high-strength elements, such as gears, brackets, or locking mechanisms, can be manufactured using metal injection molding (MIM) with alloys like MIM-4140 or MIM 17-4 PH to achieve higher fatigue or impact resistance that earlier test samples could not withstand.

Validation of Changes and Surface Optimization

Once the new prototype is built, surface treatments such as heat treatment, sandblasting, or anodizing are applied to ensure that strength, corrosion resistance, or fatigue life are preserved. Assembly issues or NVH concerns may also be addressed through insert molding or overmolding to enhance joint performance.

Rapid Iteration Capability

Because multiple prototyping technologies are available under one roof, Neway can complete redesign cycles—digital revision, prototype build, and validation testing—in a matter of days or weeks depending on complexity. This rapid iteration capability reduces project risk and supports customer timelines, particularly in EV and aerospace programs where validation cycles are time critical.