Precision Manufacturing for RF & Microwave Components

In the RF and microwave domain, manufacturing precision directly determines signal integrity and overall system performance. As the engineering team at Neway, we fully understand the extreme process requirements of high-frequency electronic components. From 5G base stations and satellite communications to radar systems and test instruments, the manufacturing quality of every RF component has a direct impact on system performance and long-term reliability.

Key Manufacturing Processes for RF and Microwave Components

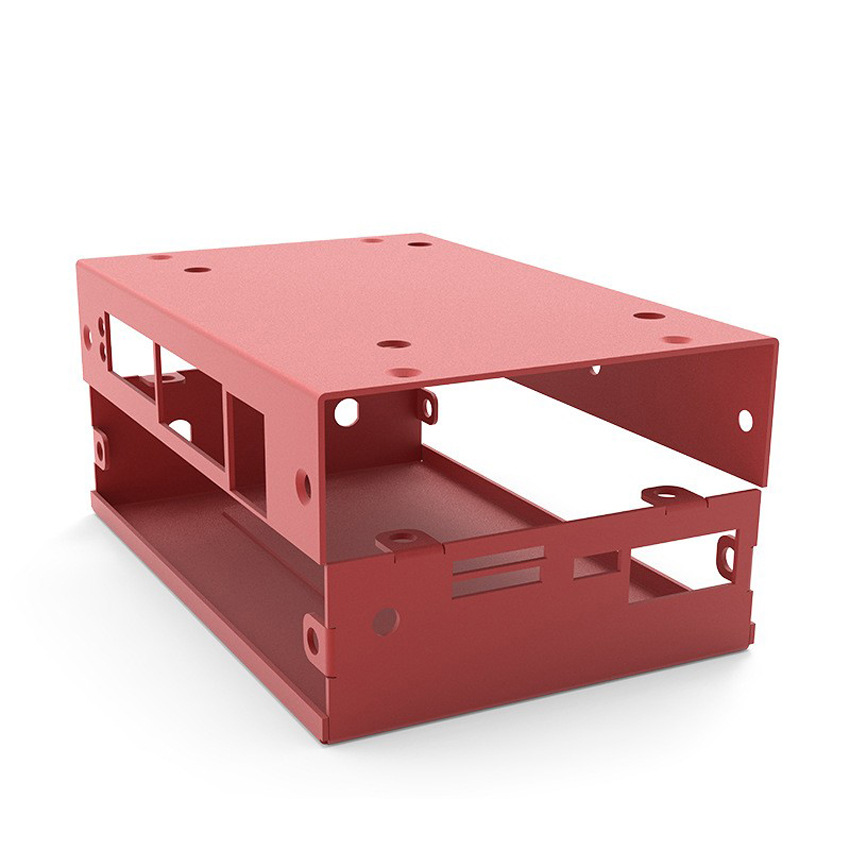

Precision Metal Forming and Machining

In RF component manufacturing, the dimensional stability of structural parts is critical to electrical performance. Our aluminum die casting technology is utilized to produce shielding housings and waveguide components, where precise mold design and process control ensure key dimensional tolerances are maintained within ±0.05 mm. This level of precision is essential for maintaining characteristic impedance and minimizing signal reflections. For more complex geometries, our sheet metal fabrication services offer flexible solutions. Through precision laser cutting and bending, we manufacture RF enclosures with excellent flatness and perpendicularity. These processes not only ensure mechanical robustness but, more importantly, guarantee stable high-frequency signal transmission.

High-Precision Connector and Contact Manufacturing

The performance of RF connectors directly affects overall signal quality. Using our metal injection molding services, we manufacture precision coaxial connector center contacts, achieving complex geometries with tight dimensional control. For higher-end connector assemblies, our CNC machining prototyping services provide ultra-smooth surfaces and accurate geometries to ensure perfect mating interfaces. We place particular emphasis on connector interface accuracy, using precision turning and grinding processes to achieve VSWR values below 1.2, thereby minimizing signal reflection and insertion loss.

Ceramic and Composite Dielectric Component Forming

In high-frequency applications, dielectric material properties are crucial. Our ceramic injection molding services enable the production of alumina and aluminum nitride components with precisely controlled dielectric constants. Through strict formulation management and optimized sintering processes, we ensure uniform microstructures and stable electrical characteristics. These ceramic components are widely used as insulators, radomes, and circuit substrates in RF systems, delivering excellent dielectric performance and thermal management capabilities—making them especially suited for high-frequency and high-power environments.

Surface Treatments for Optimized High-Frequency Electrical Performance

In RF component manufacturing, surface finishing processes have a significant impact on electrical behavior. Our electroplating technologies form uniform metallic coatings on connector contact surfaces, effectively reducing contact resistance and insertion loss. With selective silver or gold plating, we can strike a balance between premium electrical performance and cost efficiency. For components requiring extremely low surface roughness, we apply electropolishing to achieve a Ra value of ≤ 0.2 μm, which significantly reduces skin-effect-related losses at high frequencies. These precise surface treatment solutions ensure RF components maintain stable electrical characteristics over long-term operation.

Key Material Selection for RF and Microwave Components

Low-Loss Metals and Alloys

Material selection has a direct impact on RF performance. We recommend copper alloys for components requiring high conductivity, achieving an optimal balance between electrical performance and manufacturability. Through specialized heat treatment, we refine grain structure to further improve conductivity and mechanical strength. For applications requiring even lower resistive losses, we utilize high-purity copper, combined with tailored surface protection processes, to prevent oxidation, ensuring long-term stable electrical performance.

High-Performance Dielectric Materials and Ceramics

For dielectric applications, we primarily use alumina (Al₂O₃) ceramics to produce high-frequency circuit substrates and insulating components. With a stable dielectric constant (εr ≈ 9.8) and ultra-low loss tangent (tanδ ≤ 0.0002), alumina is particularly suitable for millimeter-wave applications. By precisely controlling formulations and sintering profiles, we manufacture complex three-dimensional ceramic parts that maintain excellent electrical performance and mechanical integrity under high-frequency, high-temperature conditions.

Applications of Neway Solutions in RF and Microwave Systems

Communication Infrastructure

In the telecommunication equipment sector, we provide complete RF component solutions for 5G base stations. From radiating elements in massive MIMO antenna arrays and resonant cavities in filters, to heat spreaders in power amplifiers and structural housings in transceiver modules, every component is carefully engineered and manufactured to ensure optimal performance. We focus on thermal stability, impedance control, and long-term reliability to ensure that base station systems maintain high performance across a wide range of diverse environmental conditions. Through precise electromagnetic and structural optimization, we help customers achieve higher spectral efficiency and broader, more stable coverage.

Aerospace and Defense Electronics

In the aerospace and defense sectors, RF and microwave components face even stricter reliability and environmental requirements. We manufacture precision waveguides, antenna components, and microwave modules that must perform reliably in extreme temperatures, vibration, and shock environments. Through specialized material selection and robust process design, we ensure components can withstand high-altitude environments, thermal cycling, and harsh operational conditions. For electronic warfare and advanced radar systems, our microwave components are engineered for wider bandwidths, higher power handling, and superior stability, providing dependable hardware support in complex electromagnetic environments.

Choose Neway as the Foundation of Your RF System Performance

At Neway, we have established a comprehensive RF component manufacturing system that spans electromagnetic design support, precision machining, performance validation, and volume production. Our engineering team possesses strong expertise in RF and microwave technologies, enabling close collaboration with customers from early design optimization through to manufacturability engineering. With advanced production equipment and high-frequency test capabilities, we ensure every RF component meets stringent performance specifications. We place great emphasis on process consistency, using statistical process control and real-time monitoring to maintain uniform performance across large production runs.

Conclusion: Defining the Boundaries of High-Frequency Performance with Precision Manufacturing

The precision manufacturing of RF and microwave components is an interdisciplinary challenge that integrates electromagnetics, materials science, and advanced engineering. Leveraging our deep technical foundation and extensive experience in manufacturing, Neway is committed to delivering high-performance RF component solutions to customers worldwide. We believe that through continuous technological innovation and rigorous quality control, we can help our customers push the limits of high-frequency performance and jointly drive the evolution of wireless communication technologies.

FAQ

How to design and control RF cavities to ensure resonance and shielding?

Which surface treatments best ensure long-term stability for RF connectors?

How to balance conductivity, heat, weight, and cost when selecting RF materials?

How does Neway ensure precision of RF dimensions in mass production?

What steps take RF components from prototype to full-scale production?