What design features should be avoided in rapid injection molding?

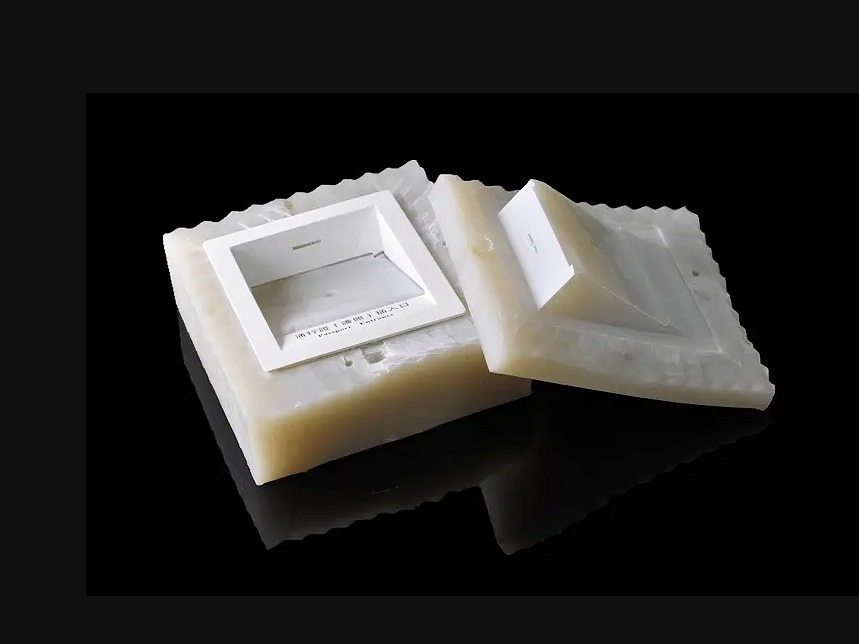

In rapid injection molding, avoiding certain design features is essential to ensure part quality, reduce tooling cost, and maintain fast turnaround times. Since rapid molds are often made from aluminum or soft steels and built for speed, not longevity, complex or tolerance-critical features can compromise performance and lead times.

Common Design Pitfalls in Rapid Injection Molding

1. Undercuts Without Adequate Justification

Undercuts require slides or lifters, which complicate mold structure and extend lead time. If unavoidable, consider parting line optimization or converting to a simpler mold design.

2. Unnecessary Tight Tolerances

Avoid calling for tolerances tighter than ±0.05 mm unless functionally critical. Tighter tolerances raise costs and extend lead times in plastic injection molding.

3. Sharp Internal Corners

Sharp corners create stress risers and are difficult to machine in aluminum tooling. Add internal radii of 0.5 mm or greater to improve mold durability and plastic flow.

4. Deep, Narrow Ribs

Excessive rib depth can cause sink marks or short shots. Maintain rib thickness at 50–60% of the wall thickness and avoid depth-to-width ratios beyond 3:1.

5. Non-Uniform Wall Thickness

Varying wall thickness causes cooling inconsistencies, warping, and shrinkage. Maintain consistent wall thickness (typically 1.5–3.0 mm) throughout the part.

6. Thin Walls in Large Surface Areas

Thin sections under 1 mm in broad areas can lead to weak or incomplete parts. Choose wall thickness based on material—for example, ABS tolerates thinner sections better than PP.

7. Textured Surfaces in Deep Cavities

Deep features with texture increase drag during ejection and can damage the mold. Increase draft angle to 2° or more if texture is required.

8. Insufficient Draft Angles

Use at least 1° per side; increase for textured or tall vertical walls. Lack of draft causes part sticking and premature tool wear.

9. Threads Without Inserts

Molded-in threads can wear out soft molds quickly. Use insert molding or secondary machining for threaded features.

10. Designs Requiring Complex Slides

Complex slide mechanisms increase cost and lead time. Optimize the design for two-part mold construction to enable faster and more economical production.

Optimize Design with Professional Support

For best results, Neway Precision offers consultative design support to ensure your parts are optimized for manufacturability. Our integrated services—from prototyping to plastic injection molding—help minimize design risks and accelerate product launch.