Can rapid molding produce parts with complex geometries?

Can Rapid Molding Produce Parts with Complex Geometries?

Unlocking Design Flexibility in Rapid Molding

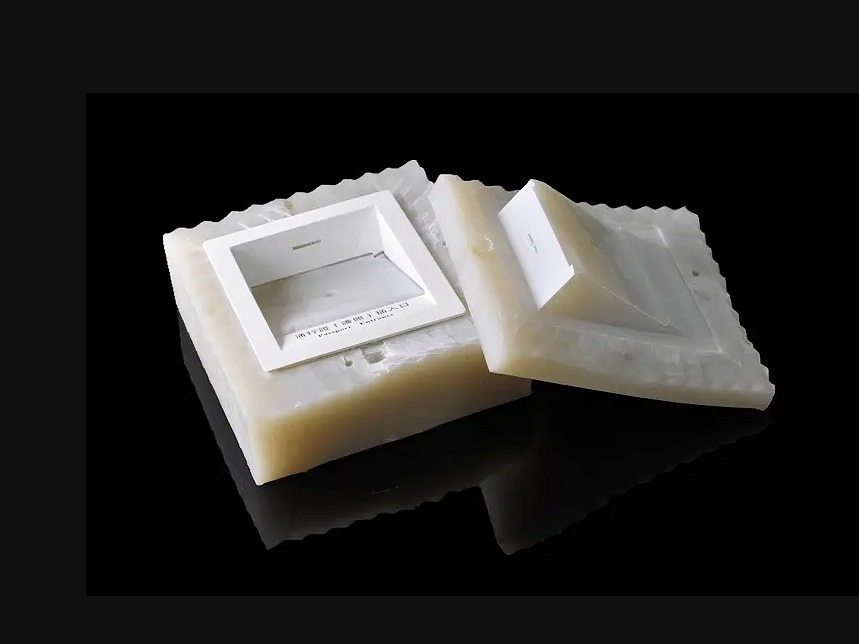

Yes—rapid molding can produce parts with complex geometries, though there are key design considerations to ensure feasibility and moldability. While traditional injection molding often requires long lead times to accommodate intricate mold features, rapid molding uses aluminum or hybrid tooling with optimized workflows to deliver geometrically complex parts in as little as 7–14 days.

Types of Complex Features Supported

Undercuts and Side Actions: Features such as snap-fits, internal lips, or latch arms can be molded using hand-loaded inserts or side-action mechanisms in aluminum tooling.

Thin Walls and Variable Thicknesses. Wall sections as thin as 0.5–0.8 mm can be molded depending on material, part size, and flow length.

Complex Surface Textures and Logos. Laser etching or EDM texturing on mold surfaces enables branding, grip textures, and decorative finishes, even in short-run production.

Multi-Cavity and Insert Molding Complex assemblies can be produced via overmolding or insert molding using pre-placed metal, plastic, or threaded components.

See Insert Molding and Overmolding capabilities

Micro-features and Fine Detail Tolerances of ±0.05 mm enable tight fits, precise snap joints, and accurate mating of parts, particularly in medical, electronic, and connector components.

Design-for-Molding Considerations

To ensure success with complex geometries:

Avoid extremely deep ribs or sharp internal corners that complicate tool release.

Maintain uniform wall thickness where possible to reduce warpage.

Collaborate with tooling engineers for mold flow analysis and gate placement optimization.

When to Transition to Traditional Molding

If part complexity requires:

Advanced cooling channels (e.g., conformal cooling)

Ultra-high-volume production

Tool life beyond 50,000 cycles. Then, traditional injection molding with hardened steel tooling is recommended.

Neway’s Capability in Complex Rapid Molded Parts

Neway supports complex part production with:

DFM review for moldability feedback

Side-action, insert, and hybrid tooling for intricate features

Material consulting to match flow, strength, and tolerance requirements

With fast lead times, ±0.05 mm accuracy, and the ability to support complex part geometry, Neway delivers high-performance results in record time.