Why is CNC machining preferred over traditional machining methods for critical applications?

Why Is CNC Machining Preferred Over Traditional Machining Methods for Critical Applications?

The Strategic Advantage of CNC Machining in High-Precision Industries

CNC (Computer Numerical Control) machining is widely preferred over traditional manual methods in critical industries such as aerospace, medical devices, energy, and defense. The core advantages lie in its precision, consistency, automation, and ability to produce complex geometries with minimal human error. These capabilities are essential for applications where tolerances as tight as ±0.01 mm or better are non-negotiable.

1. Superior Precision and Repeatability

CNC machines execute digitally programmed toolpaths that ensure identical results across thousands of units. In contrast, manual machining often varies based on operator skill.

CNC Tolerances: Typically ±0.01 mm, and even ±0.002 mm in high-end setups.

Applications: Jet engine components, surgical implants, semiconductor tooling.

2. Complex Geometry and Multi-Axis Capabilities

With 3-, 4-, and 5-axis machining, CNC systems can create intricate features, undercuts, and compound angles in a single setup—impossible or inefficient using manual techniques.

Example: 5-axis CNC is essential for parts like turbine impellers or spinal fusion cages.

3. Automation and Consistency

CNC machining integrates real-time feedback systems, tool wear compensation, and automatic tool changers. These features reduce downtime, eliminate manual variation, and improve throughput.

Result: Higher yield rates and lower defect percentages—typically under 1%.

4. Material Versatility

CNC machining supports a wide range of high-performance materials, including:

Titanium for aerospace and biomedical components

Inconel and other superalloys for heat and corrosion resistance

Tool steel for hardened molds and dies

These materials are often too hard or complex for efficient manual machining.

5. Integrated Quality Control

CNC systems can incorporate in-process measurement tools such as laser scanners or touch probes. Combined with post-process CMM inspection, this ensures that each part meets ISO 2768 or tighter specifications.

6. Reduced Human Error and Labor Dependency

Manual machining relies heavily on operator experience, increasing the risk of inconsistency. CNC automation reduces these risks, especially in industries requiring traceability and process validation, such as medical device manufacturing under ISO 13485.

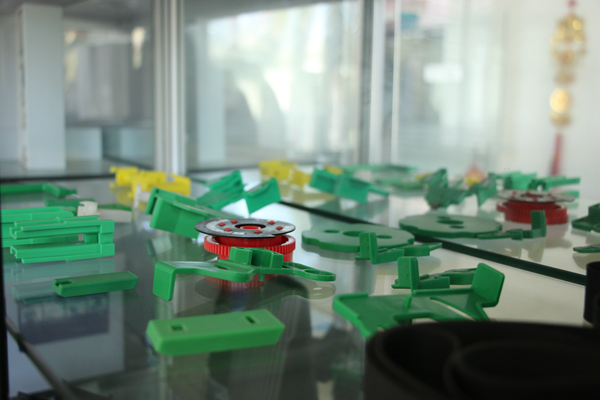

Manufacturing Support for Critical Applications

Neway delivers precision machining solutions with:

CNC Prototyping to validate geometry and tolerance

Superalloy CNC Machining for high-temperature and high-load environments

Material Consultation to select alloys that support durability, machinability, and compliance

With ±0.01 mm repeatability, automated quality control, and 20+ years of manufacturing experience, Neway is trusted by engineers and buyers in the most demanding sectors.