What materials are commonly used in industrial 3D printing?

What Materials Are Commonly Used in Industrial 3D Printing?

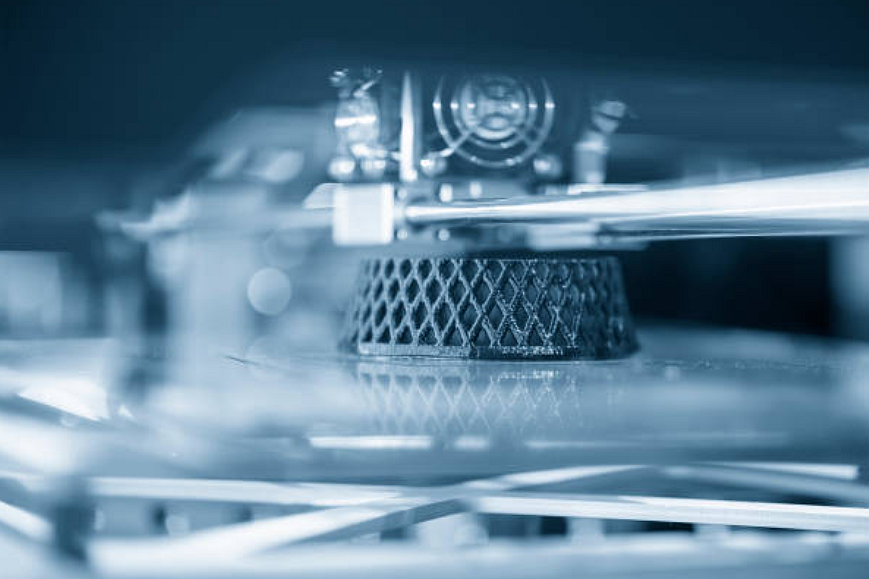

Overview of Industrial-Grade 3D Printing Materials

Industrial 3D printing uses a broad range of engineering polymers, high-performance metals, and ceramics to meet the performance demands of aerospace, automotive, medical, and energy sectors. Each material is selected based on mechanical strength, thermal resistance, chemical stability, and process compatibility. Neway's 3D printing services support these materials through advanced processes like SLS, DMLS, SLA, and FDM.

Common Metal Materials

Aluminum Alloys

AlSi10Mg: Lightweight and strong, suitable for structural components and heat exchangers

Use Cases: Automotive brackets, aerospace housings

Learn More

Titanium Alloys

Ti-6Al-4V (Grade 5): Exceptional strength-to-weight ratio and biocompatibility

Use Cases: Medical implants, turbine blades, aerospace fasteners

Nickel-Based Superalloys

Inconel 625, 718: High-temperature resistance and corrosion performance

Use Cases: Jet engine parts, chemical processing components

Tool Steels

H13, M2: High hardness and wear resistance for tooling and mold inserts

Common Plastic and Composite Materials

Nylon (PA12, PA6)

Excellent wear resistance and flexibility

Used in SLS for enclosures, jigs, and functional parts

PEEK (Polyether Ether Ketone)

High strength, thermal stability (up to 250°C), and chemical resistance

Preferred in medical, aerospace, and oil & gas

Ultem (PEI)

Flame-retardant, stable up to 200°C, and ideal for electrical applications

ABS and PC

Carbon-Fiber Filled Filaments

Reinforced thermoplastics (e.g., Nylon + CF) for added stiffness and strength

Ideal for structural and lightweight applications

High-Performance Resin Materials

Standard Resins: Used in SLA for prototyping

Engineering Resins: High-temperature, flexible, or tough resins for functional parts

Biocompatible Resins: Used for surgical guides, dental applications

Supporting Material Selection Services

Neway provides tailored consultation for:

Material Selection based on application, geometry, and environment

Hybrid Manufacturing with CNC finishing for optimal strength and precision

Rapid Prototyping to validate material behavior and form-fit function

With ±0.01 mm accuracy, certified raw materials, and global delivery, Neway ensures industrial-grade reliability across a full range of 3D printing materials.