Are there any limitations or challenges associated with green sand casting?

Surface Finish and Dimensional Accuracy

While green sand casting offers sustainability and cost-effectiveness, it can present limitations in surface finish and dimensional precision. The texture of the molding sand can result in a slightly rough surface, compared to smoother methods such as investment casting or die casting. Post-processing techniques, such as polishing or electropolishing, are often required to achieve tight surface requirements or achieve aesthetic finishes.

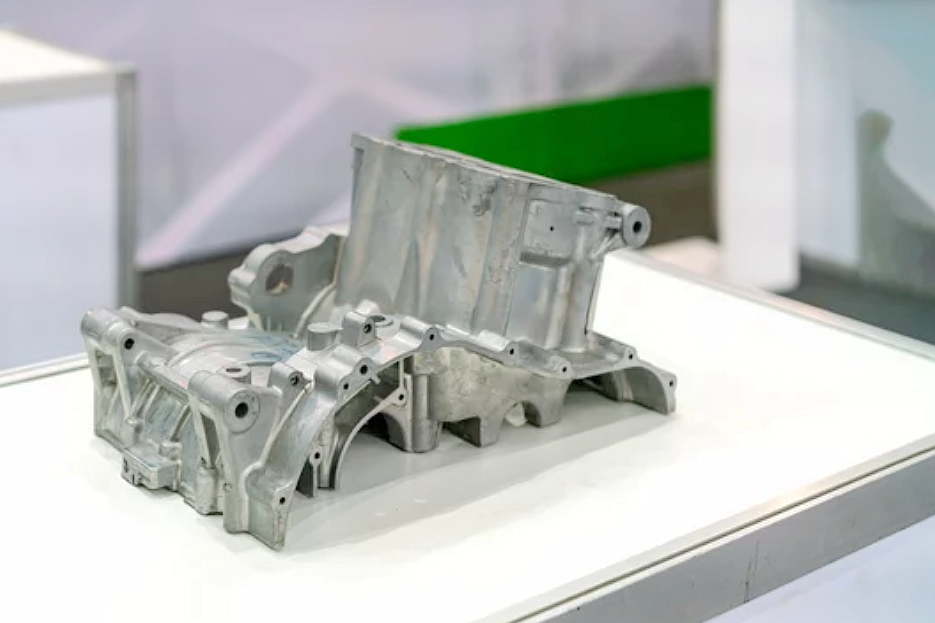

Limited Suitability for Thin-Walled or Complex Parts

Green sand molds are less ideal for components with thin walls or intricate internal passages. The sand’s mechanical strength and permeability restrict how finely details can be cast without distortion or collapse. For high-precision parts, processes such as metal injection molding (MIM) or ceramic injection molding (CIM) offer superior dimensional control and repeatability.

Moisture-Related Defects

Because green sand relies on water and clay as binders, improper moisture control can cause gas porosity, blowholes, or rough surfaces. Excess moisture leads to steam generation during pouring, while dryness reduces mold cohesiveness. Consistent sand conditioning and moisture monitoring systems are critical to maintaining process stability.

Strength and Mold Erosion Issues

At high pouring temperatures—especially for alloys such as cast steel or nickel-based alloys—the mold may erode or lose dimensional integrity. This can result in sand inclusions or metal penetration defects. Foundries counter this by optimizing sand grain distribution, using chemical additives, or developing stronger hybrid sand formulations.

Size and Weight Constraints

Although green sand casting handles a wide range of sizes, extremely large or heavy components may require specialized equipment for compaction, handling, and shakeout. For high-volume production or heavy-duty alloys, complementary techniques like gravity casting or precision casting may be more efficient.

Process Variability and Control

Variations in sand composition, grain size, and moisture can introduce dimensional drift between batches. Modern foundries address this challenge using automated sand preparation and real-time monitoring systems. Additionally, simulation tools help predict mold filling and solidification, minimizing scrap and ensuring uniform quality.

Post-Processing Requirements

Due to the nature of green sand molds, additional machining or surface treatment is often necessary to achieve final tolerance and finish. Processes such as anodizing or powder coating enhance both corrosion resistance and appearance, but add cost and processing time.

Environmental and Emission Controls

Although inherently more sustainable than resin-bonded processes, green sand casting still produces dust and binder emissions that require capture and filtration. Installing dust collection and ventilation systems ensures compliance with environmental regulations and promotes a safe workplace.