What validation needs apply to high-voltage safety components?

High-voltage safety components used in e-mobility and automotive applications require stringent validation to ensure insulation strength, thermal stability, mechanical robustness, and long-term reliability under vibration, humidity, and voltage cycling. These components—such as battery connectors, busbars, HV housings, power distribution modules, and inverter enclosures—must meet both electrical safety standards and mechanical durability targets before entering production.

Electrical Insulation and Dielectric Testing

Validation begins with dielectric withstand and insulation resistance testing to prevent arc-over or short circuits under high voltage. Plastic housings produced through injection molding using materials like Ultem (PEI) and polycarbonate are assessed for breakdown voltage, tracking resistance, and creepage distance. When metal elements are included, overmolding or insert molding technology is used to achieve full insulation coverage.

Thermal and Environmental Validation

Because high-voltage components operate near heat sources, materials are tested for thermal expansion, aging, and retention of dielectric strength after prolonged exposure. Structural housings manufactured via aluminum die casting or precision casting can be coated with thermal barrier coatings to prevent electrical breakdown due to heat. Cycling tests simulate hundreds of charge-discharge cycles to ensure insulation integrity over time.

Environmental validation includes humidity, salt-spray, and dust ingress testing. Processes such as nitriding, powder coating, and passivation help prevent corrosion and failure of metallic contacts in harsh operating environments.

Mechanical Strength and Assembly Validation

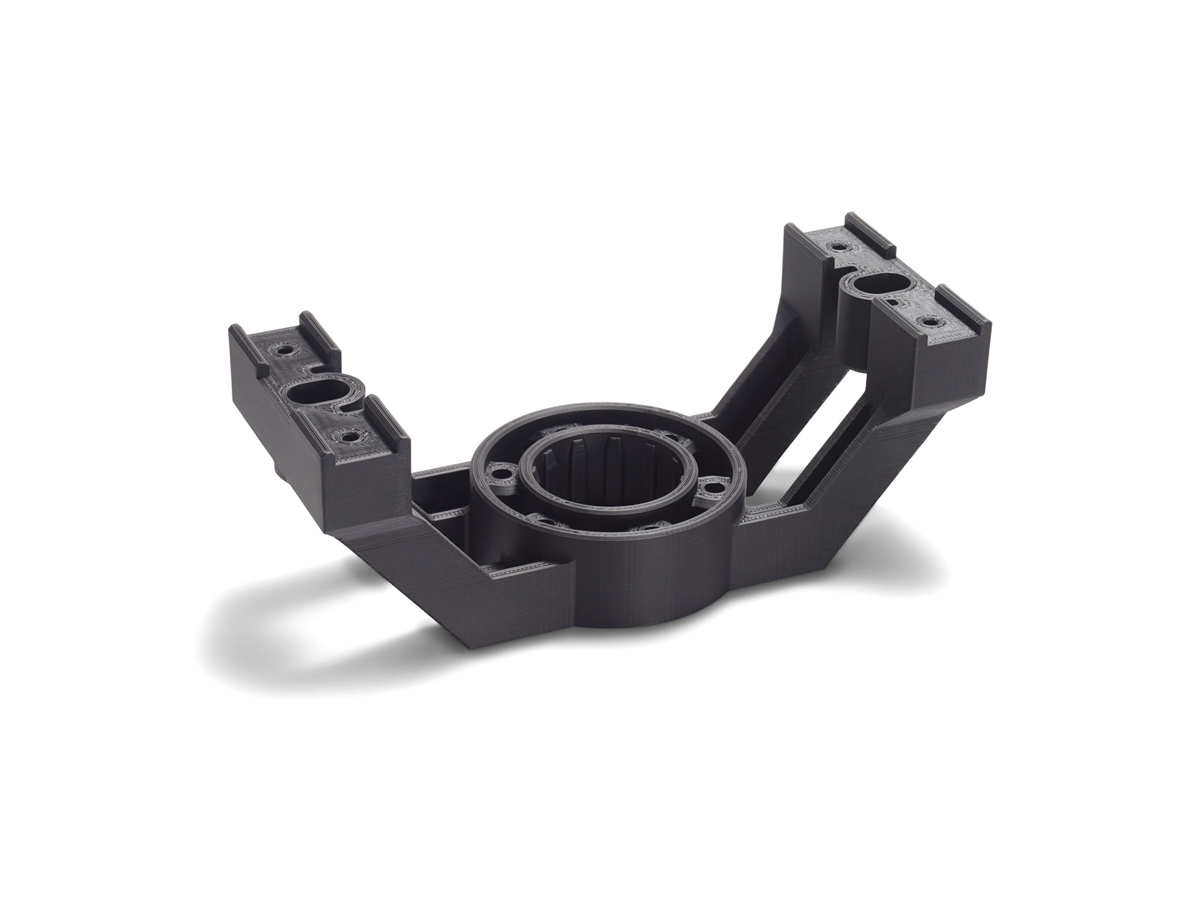

Mechanical stresses caused by vibration, vehicle motion, and assembly torque must be validated early in development. Functional prototypes are produced via CNC machining prototyping and later refined using rapid molding prototyping or injection molding to assess assembly fit, torque resistance, creep behavior, and deformation under load.

For threaded fasteners and connector interfaces, test validation includes pull-out force, socket alignment, and durability under repeated mating cycles. For reinforced plastic housings, metal inserts are used for improved torque resistance via insert molding.

Electromechanical and Functional Testing

High-voltage systems require functional validation under real EV duty cycles. Busbars, terminal boards, and HV modules are tested on rigs that simulate transient current peaks, regenerative braking events, and sudden voltage reversals. Thermal imaging of prototypes—especially those made via aluminum die casting—helps detect hot spots at interfaces or housing walls.

For complex HV safety modules, complete assemblies undergo integrated validation with hardware-in-the-loop testing to confirm coordinated performance of thermal management, electrical protection, and mechanical durability.