Compare the Material Density and Mechanical Properties of MIM and Forged Parts

Introduction

Introduction

Manufacturing processes play a pivotal role in determining the properties and performance of metal components. Two prominent methods, Metal Injection Molding (MIM) and forging, are frequently used in various industries. Understanding the distinctions between these two processes, particularly in terms of material density and mechanical properties, is crucial for engineers and product designers seeking to optimize component performance, durability, and cost efficiency.

Section 1: Understanding Metal Injection Molding (MIM)

1.1 What is Metal Injection Molding?

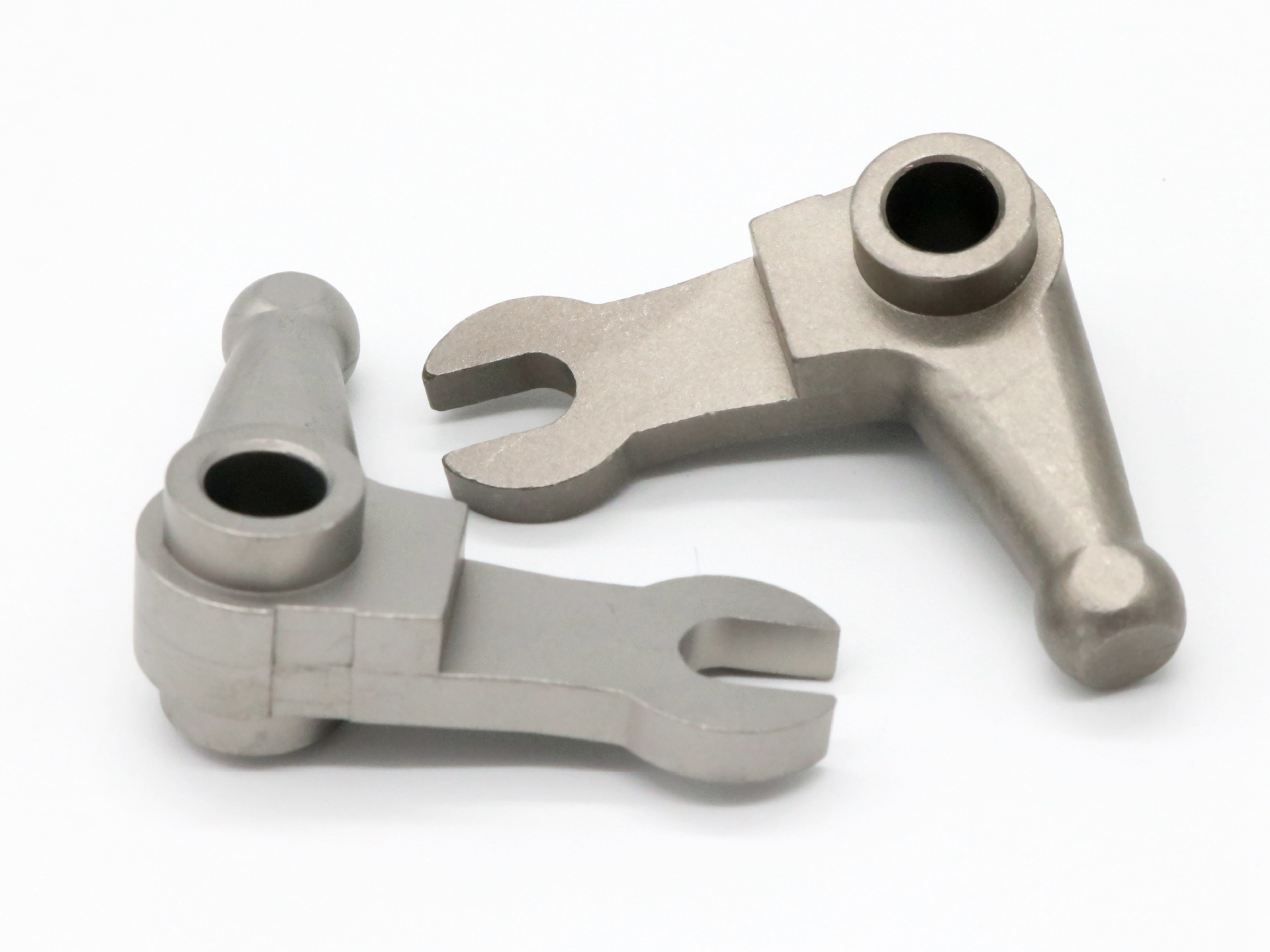

Metal Injection Molding (MIM) is a manufacturing technique that merges powder metallurgy with plastic injection molding. This innovative method combines fine metal powders and polymer binders, which are injected into molds and subsequently sintered to achieve the desired properties. Typical materials include stainless steel, titanium, and tungsten alloys, making MIM especially valuable in producing intricate, precision components widely used in electronics, medical devices, and automotive sectors.

1.2 Advantages and Limitations

MIM excels at producing highly complex geometries with tight tolerances, enabling the creation of precise, detailed parts without requiring extensive post-processing. It is particularly advantageous for high-volume production runs due to automated processes and minimal waste. Nevertheless, inherent porosity due to the sintering stage can reduce the density and mechanical performance of MIM-produced parts, potentially limiting their application in scenarios involving extreme stress or impact conditions.

Section 2: Understanding Forging

2.1 What is Forging?

Forging involves shaping metal through compressive force, performed at various temperatures (hot, warm, or cold forging). The forging process reshapes metal billets into strong, robust components with minimal internal defects. Commonly forged metals include alloy steels, aluminum, and titanium. Forging is frequently employed in high-performance industries, including automotive, aerospace, and heavy machinery manufacturing.

2.2 Advantages and Limitations

Forging significantly enhances mechanical properties, such as strength, durability, and fatigue resistance, through grain refinement and alignment. Forged components exhibit near-perfect density, greatly reducing porosity and enhancing reliability under high stress. However, forging is less economically viable for intricate or smaller-scale components due to higher initial tooling expenses and additional machining operations.

Section 3: Comparative Analysis of Material Density

3.1 Density Characteristics of MIM Parts

Due to residual porosity, MIM components typically have densities ranging from 95% to 99% of their theoretical values. This moderate porosity can negatively influence component strength, especially under cyclic stresses or impact loads, thereby restricting MIM's suitability for high-demand scenarios such as critical aerospace applications.

3.2 Density Characteristics of Forged Parts

Forged components attain densities approaching nearly 100%, thanks to extensive compressive forces applied during processing. This near-complete density drastically reduces internal porosity, significantly improving component strength and durability.

3.3 Direct Comparison of Density

Property | MIM Parts | Forged Parts |

|---|---|---|

Density | 95%-99% theoretical | Nearly 100% theoretical |

Porosity | Moderate, affecting performance | Minimal, enhancing performance |

Performance implications | Suitable for less critical applications | Ideal for demanding applications |

Density is directly linked to performance; forging clearly surpasses MIM by offering fewer internal defects and superior structural integrity.

Section 4: Comparative Analysis of Mechanical Properties

4.1 Mechanical Properties of MIM Parts

Parts produced through MIM generally exhibit moderate levels of tensile strength, hardness, and ductility. Their mechanical performance is sufficient for many applications; however, porosity inherent to the sintering process may compromise fatigue resistance and impact toughness. Despite these limitations, MIM remains a viable choice for parts where intricate geometry and precision are prioritized over maximum strength.

4.2 Mechanical Properties of Forged Parts

Forging provides exceptional mechanical properties, including high tensile strength, excellent hardness, superior ductility, and outstanding fatigue and impact resistance. These properties result from the grain refinement and alignment achieved during the forging process, making forged components highly suitable for stress-critical applications.

4.3 Direct Comparison of Mechanical Properties

Property | MIM Parts | Forged Parts |

|---|---|---|

Tensile Strength | Moderate | High |

Hardness & Ductility | Moderate | Excellent |

Fatigue Resistance | Moderate | Excellent |

The mechanical advantages of forging are evident, particularly in applications that require stringent mechanical performance standards.

Section 5: Selecting Between MIM and Forging

5.1 Production Volume and Economic Considerations

MIM is cost-effective for producing complex shapes in high volumes due to automation and minimal waste generation. Conversely, forging is preferable for lower volumes where the higher tooling cost can be offset by the demand for superior mechanical properties and durability.

5.2 Complexity and Design Freedom

MIM offers significant advantages in achieving complex geometries without extensive machining, thus streamlining production and reducing costs. On the other hand, forging is typically constrained to simpler shapes due to the inherent limitations of the compressive shaping process.

5.3 Performance Requirements

For components with stringent strength and durability requirements, such as automotive or aerospace parts, forging is typically the best choice. MIM offers a practical and cost-effective alternative for smaller, intricate components with moderate mechanical requirements.

Section 6: Industry Applications and Case Studies

6.1 Medical Device Industry

MIM effectively produces intricate, precise components for surgical instruments and implantable devices in medical device manufacturing. In contrast, forging is used for robust, high-load-bearing components, such as orthopedic implants, which demonstrate superior mechanical properties.

6.2 Automotive Industry

Forged components, such as connecting rods and crankshafts, showcase superior durability and fatigue resistance. MIM complements forging by producing smaller, intricate parts, such as sensors, valves, and precision-engineered internal components.

Conclusion

Metal Injection Molding and forging each have unique advantages and limitations. Choosing the right manufacturing process depends on several factors, including production volume, design complexity, mechanical property requirements, and cost-efficiency. By thoroughly understanding these factors and their implications on component quality and performance, manufacturers can make informed decisions to optimize product performance, longevity, and overall value.