CNC Milling Service: Processes, Materials, and Applications

Introduction to CNC Milling

CNC milling is a cornerstone of modern manufacturing, harnessing the power of computer numerical control (CNC) to transform digital designs into precise physical parts. This process utilizes multi-axis milling machines equipped with cutting tools that systematically remove material from a workpiece, shaping it according to specifications programmed into the machine's computer.

What is CNC Milling?

CNC milling is a subtractive manufacturing technique where the desired form is achieved by systematically removing material from a solid block, known as the workpiece, using rotary cutting tools. As a versatile and powerful tool, CNC milling can operate along various axes, offering a significant advantage over traditional manufacturing methods. This ability allows for creating complex and intricate parts with high precision and excellent finish, essential in many high-tech industries.

Distinctive from Other CNC Processes

Unlike CNC turning, where the workpiece rotates against a fixed cutting tool, CNC milling primarily involves moving the workpiece against the milling cutter. Milling machines can operate on up to five axes, providing geometric complexity that surpasses other techniques like CNC turning, which typically works around a single axis. This fundamental difference empowers CNC milling to handle more complex projects, making it ideal for components that require intricate detailing and elaborate shapes.

The CNC Milling Process

The CNC milling process is a sophisticated and meticulously planned series of steps that turn a concept into a high-quality, precision-engineered part. Each process stage ensures that the final product meets all specified requirements. Here’s a detailed look at each step involved in CNC milling:

1. Design and CAD Model Creation

The journey of a CNC-milled part begins with design. Engineers use Computer-Aided Design (CAD) software to create a detailed 3D model of the part. This model includes all critical dimensions, tolerances, surface finish requirements, and material specifications. It serves as the blueprint from which the machine will work.

2. CAM Processing and Setup

Once the CAD model is completed, it must be converted into a machine-readable format that the CNC machine can understand. It is done using Computer-Aided Manufacturing (CAM) software, which translates the 3D model into a series of precise instructions—G-code—that guide the CNC machine on where, how, and when to move its tools.

3. Material and Tool Selection

Choosing a suitable material for the part is essential. It depends on the intended use of the final product, including factors like strength, temperature resistance, and impact tolerance. Simultaneously, the correct selection of tools (end mills, drills, threading taps) is vital for effective milling. Tools are chosen based on material hardness, cutting speed, and finish quality desired.

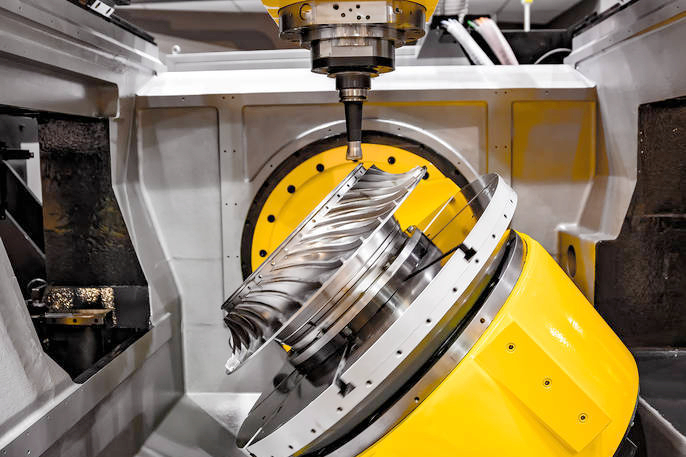

4. Milling Operation

With the design loaded and tools set, the actual milling operation begins. The raw material block is securely fixed on the machine bed, and the tools are precisely positioned. The CNC machine then executes the G-code, with the milling cutter moving along the designated axes to cut away material, shaping the workpiece as designed. The process might involve multiple tool changes and adjustments to achieve the correct depth, angles, and finishes.

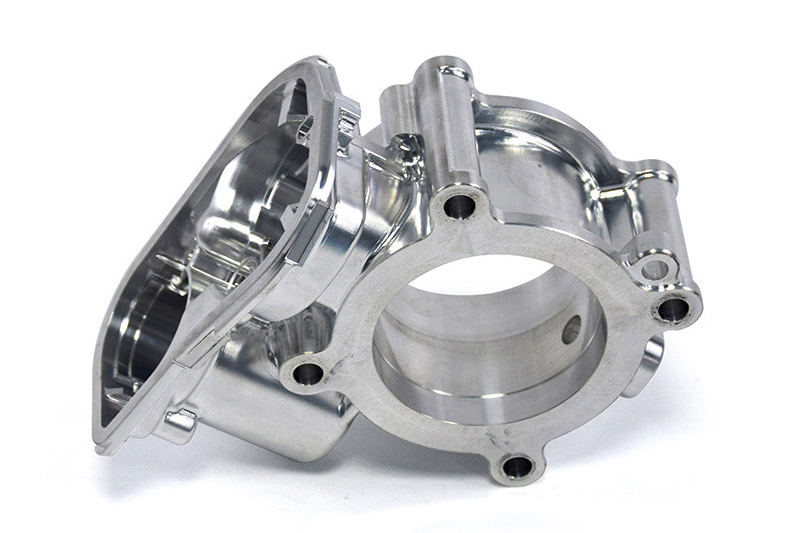

5. Finishing Processes

After the primary milling, the part may undergo additional finishing processes. These can include secondary operations like drilling, threading, or deburring to remove sharp edges. Surface finishing techniques such as sanding, bead blasting, or anodizing might improve appearance, corrosion, or wear resistance.

The CNC milling process is a perfect blend of modern technology and precision engineering, enabling the production of parts with complex shapes and high tolerances. This capability enhances functionality and broadens the scope of applications for CNC-milled components across various industries.

Materials Used in CNC Milling

Selecting the appropriate material is a critical decision in CNC milling, as it directly influences the final product's mechanical properties, durability, and application suitability. Here's a breakdown of the most commonly used materials in CNC milling, each chosen for its unique attributes and performance characteristics:

1. Metals

Aluminum: Known for its lightweight and corrosion resistance, aluminum is one of the most commonly used metals in CNC milling. It is easy to machine and provides an excellent strength-to-weight ratio, making it ideal for aerospace, automotive, and consumer electronics.

Stainless Steel: Valued for its strength and excellent corrosion resistance, it is often used in medical devices and food processing equipment. It can withstand harsh environments and is known for maintaining its integrity over various temperatures.

Titanium: This metal is strong and lightweight, with outstanding corrosion resistance and the ability to withstand extreme temperatures. Titanium is commonly used in aerospace and medical applications due to its biocompatibility.

Brass: Easy to machine and naturally corrosion-resistant, brass is often used for plumbing fixtures, electrical components, and decorative items. Its low friction coefficient makes it suitable for gears and doorknobs.

2. Plastics

ABS (Acrylonitrile Butadiene Styrene): A standard thermoplastic part that's tough and impact-resistant, ABS is frequently used in automotive components, consumer goods, and enclosures for household appliances.

Polycarbonate: This material is known for its strength, impact resistance, and transparency, making it ideal for protective gear, automotive headlights, and various medical applications.

PEEK (Polyether Ether Ketone): Offering a unique combination of high-temperature resistance, mechanical strength, and chemical resistance, PEEK is often used in aerospace, automotive, and medical implant applications.

3. Composites

Carbon Fiber-Reinforced Polymer (CFRP): Known for its exceptional strength-to-weight ratio and stiffness, CFRP is extensively used in the aerospace, automotive, racing, and sports equipment industries. It offers significant advantages where weight reduction is critical without compromising strength.

Choosing the Right Material

The selection process considers several factors:

Mechanical Properties: Includes tensile strength, elasticity, and hardness.

Physical Properties: Such as thermal stability and electrical conductivity.

Chemical Resistance: Important for parts exposed to harsh environments.

Machinability: Some materials are more accessible to machines, affecting tool wear and machining time.

Understanding the properties of these materials helps manufacturers tailor the CNC milling process to meet specific application requirements, ensuring optimal performance and durability of the milled parts. This comprehensive selection enables industries to innovate and develop products that push the boundaries of what's possible with CNC technology.

Advantages of CNC Milling

CNC milling is a highly favored manufacturing process, appreciated for its precision, versatility, and efficiency. Below are the key advantages that make CNC milling an essential tool in modern manufacturing:

1. Precision and Repeatability

One of the standout benefits of CNC milling is its ability to produce parts with high precision. Modern CNC mills can achieve tolerances as tight as ±0.001 inches or finer, depending on the machine and material used. This level of accuracy is crucial for industries where even the slightest deviation can affect the component's functionality, such as in aerospace and medical devices.

2. Complex Geometries

CNC milling machines operate on multiple axes—typically at least three (X, Y, and Z) and often more. This capability allows for creating parts with complex shapes and features that would be difficult or impossible to replicate using manual machining processes. Intricate cuts, deep holes, and fine details are all possible, providing designers with a high degree of creative freedom.

3. Efficiency and Speed

Once the CNC machine is set up and the program is loaded, it can produce parts quickly and continuously with minimal supervision. This automated aspect of CNC milling significantly reduces the lead times and increases productivity, especially for high-volume production runs. The speed and efficiency of CNC milling save time and reduce labor costs, making it a cost-effective solution for both small and large-scale productions.

4. Flexibility in Production

CNC milling is highly adaptable to changes in the production process. Suppose a modification in part design is required. In that case, it can be achieved by simply updating the software without changing the physical setup. This flexibility is precious in prototype development, where iterative design changes are expected.

5. Reduced Waste

CNC milling is a subtractive manufacturing process that produces minimal waste compared to other fabrication techniques. The precision of the process means that only the necessary material is removed, and advanced software can optimize cutting paths to maximize material usage.

6. Enhanced Safety

Operating under automated control, CNC milling machines reduce the risk of accidents commonly associated with manual machining. Operators are not required to be in close contact with the cutting tools, further increasing workplace safety.

Applications of CNC Milling

CNC milling is indispensable in many industries due to its versatility and high precision. This section explores some of the primary applications of CNC milling, showcasing its broad utility in various fields:

1. Aerospace

The aerospace industry demands components that meet incredibly high standards of accuracy and reliability. CNC milling produces parts like engine brackets, control panels, and structural components for aircraft and spacecraft. These parts must withstand extreme conditions and require lightweight, robust materials like titanium and aerospace-grade aluminum.

2. Automotive

In automotive manufacturing, CNC milling is essential for creating complex engine parts, transmission components, and custom modifications. These components must be highly durable and precise to ensure the vehicle's performance and safety. CNC milling allows for producing these complex parts at high volumes with consistent quality.

3. Medical

Precision is critical in the medical field, where CNC milling is used to manufacture surgical tools, implants, and orthotic devices. Materials like stainless steel and titanium are commonly milled to meet medical applications' stringent sterility and compatibility requirements. The ability to produce these components with high precision ensures their effectiveness and safety in medical procedures.

4. Electronics

CNC milling plays a crucial role in the electronics industry, particularly in the fabrication of enclosures, heat sinks, and other structural components of electronic devices. These parts often require precise dimensions and thermal properties to protect sensitive electronics and ensure efficient operation.

5. General Manufacturing

Beyond these specialized industries, CNC milling is also widely used in general manufacturing for creating fixtures, jigs, and machinery components. Its ability to handle a variety of materials and complex shapes makes it a versatile tool for producing custom parts and improving manufacturing processes.

6. Prototyping and R&D

CNC milling is invaluable in product design, research, and development, allowing engineers to produce and test prototypes quickly. It speeds up the innovation process, enabling designers to iterate on designs rapidly and test functionalities before going into mass production.

These diverse applications highlight the flexibility of CNC milling to adapt to different materials and design specifications, making it a fundamental technology in both traditional and cutting-edge manufacturing sectors. By leveraging the capabilities of CNC milling, industries can achieve higher efficiency, reduce time to market, and maintain competitive edges in their respective fields.

Innovations and Future Trends in CNC Milling

As a cornerstone of manufacturing, CNC milling continuously evolves through technological advancements. This section explores recent innovations and anticipates future trends to redefine this essential machining process.

Recent Advancements

Automation and Robotics: Integrating automated loading systems and robotic arms has streamlined the CNC milling process, reducing manual labor and enhancing precision. These advancements allow continuous operation, even in unsupervised settings, significantly boosting productivity.

High-Speed Machining: Modern CNC milling machines are equipped with capabilities for high-speed machining, which include faster spindle speeds, rapid feed rates, and advanced tool paths. It enables quicker material removal with finer finishes, reducing cycle times and increasing throughput.

Adaptive Control Technology: Some CNC milling machines now incorporate adaptive control systems that adjust cutting conditions in real time based on feedback from sensors monitoring the machining process. It helps optimize tool life, prevent failure, and ensure consistent quality across parts.

Conclusion

CNC milling is fundamental to modern manufacturing, offering unparalleled precision, versatility, and efficiency. Throughout this article, we have explored the essential processes involved in CNC milling, the variety of materials that can be machined, and the numerous applications across diverse industries. We've also delved into the significant advantages of CNC milling and highlighted the latest innovations and future trends shaping its evolution.

The importance of CNC milling in modern manufacturing cannot be overstated. It is critical in producing complex and precise components necessary for the aerospace, automotive, medical, and electronics industries. As technology advances, CNC milling will remain at the forefront of manufacturing innovations, driving productivity, quality, and sustainability improvements.

Whether you are involved in high-volume production or customized manufacturing, understanding and leveraging the capabilities of CNC milling is crucial for staying competitive in the fast-paced world of industrial production. It is a technology that not only supports the current demands of manufacturing but also adapts to future challenges and opportunities.

Start Your Project Today

Are you looking to enhance manufacturing processes with high-precision and efficient CNC milling services? Contact us at Neway to explore how our state-of-the-art CNC milling solutions can meet your specific needs. Our team of experts is ready to assist you in integrating the latest CNC technologies into your production lines, ensuring your products are manufactured to the highest standards. Visit our website or reach out directly to discuss your project and see how we can help you achieve your manufacturing goals.

With Neway's expertise in CNC milling, you can ensure that your projects are not just completed but are done with the utmost precision and efficiency, tailored to the demands of your industry.