Beyond Basics: Adding Functional Sophistication Through Over Molding

Introduction

Overmolding technology represents a substantial leap beyond traditional manufacturing, significantly enhancing product functionality and aesthetics. This advanced form of plastic injection molding enables manufacturers to produce products with superior ergonomics, durability, and multi-functional integration. As market competition intensifies and user expectations rise, overmolding is indispensable for elevating product design and performance in industries such as automotive, healthcare, and consumer electronics.

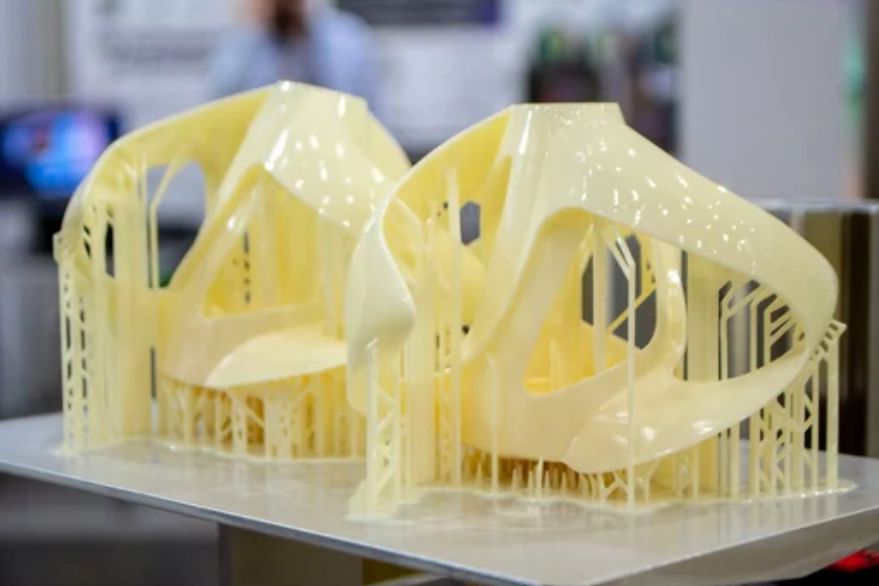

Exploring Overmolding

Overmolding involves encapsulating a rigid substrate, such as metal or hard plastic, with a softer elastomer or thermoplastic elastomer (TPE). This method enhances the physical attributes of products, enabling sophisticated designs that significantly boost both form and function beyond traditional single-material approaches.

How Overmolding Enhances Product Design

Aesthetic Enhancement: Facilitates unique textures, multi-color designs, and visually appealing finishes.

Functional Improvement: Provides layers of protection, improved ergonomics, and advanced features such as shock absorption and enhanced grip.

Introducing advanced materials, such as TPU, silicone, and bio-based elastomers, allows designers to push the boundaries of product capabilities and market appeal.

Key Functional Advantages of Overmolding

Enhanced Ergonomics and User Comfort

Overmolding significantly enhances ergonomics, particularly in handheld and wearable products. Soft-touch materials, such as thermoplastic elastomers (TPE) or silicone, provide excellent grip and tactile feedback, significantly enhancing user comfort and safety while reducing fatigue during extended use.

Integration of Multiple Functions

Overmolding seamlessly integrates multiple functions into single components, such as sealing, vibration damping, and ergonomic gripping surfaces. This integration simplifies assembly, reduces manufacturing complexity, and lowers production costs while enhancing functionality, which is crucial in applications such as power tools.

Increased Durability

Products fortified with over-molding exhibit superior resilience against daily wear, environmental stresses, and accidental impacts. The protective layer of durable materials like TPU or silicone effectively mitigates damage from abrasions, drops, and harsh environmental exposure, significantly extending product lifespan and reliability.

Selecting the Right Materials for Overmolding

Optimal material selection is crucial for achieving successful overmolding. Proper pairing of the substrate and overmold material ensures robust adhesion, enhanced product durability, and functional integrity.

Importance of Material Compatibility

Ensuring chemical compatibility between substrates and overmolding materials, such as TPU or silicone, is fundamental. Proper compatibility ensures adhesion and significantly improves product longevity, durability, and reliability in demanding applications, such as medical devices.

Popular Overmolding Materials and Their Benefits

Thermoplastic Elastomers (TPE): Offer superior flexibility, chemical resistance, and ergonomic grip, ideal for consumer and automotive products.

Thermoplastic Polyurethane (TPU): Known for durability, abrasion resistance, and exceptional performance in harsh conditions.

Silicone: Highly biocompatible, temperature-resistant, and flexible, essential for medical and food-grade applications.

Factors Influencing Material Selection

Selecting suitable overmolding materials involves considering application-specific performance demands, cost constraints, and desired aesthetics. A balanced selection ensures products meet both functional requirements and consumer expectations for quality and reliability.

Real-World Examples and Industry Applications

High-Performance Automotive Components

In automotive applications, overmolding significantly enhances interior components, including gear shift knobs, steering wheels, and control panels. Materials like TPU and TPE offer improved ergonomics, reduced vibration, and enhanced durability, which are essential for automotive safety and user comfort.

Precision Medical Devices

Medical devices extensively leverage silicone and TPE overmolds for improved durability, precision, and ergonomics. Surgical instruments, diagnostic tools, and wearable medical monitors greatly benefit from these biocompatible materials, ensuring reliability even after undergoing repetitive sterilization processes.

Advanced Consumer Electronics

Overmolding technology is widely used in consumer electronics, resulting in aesthetically pleasing, robust, and comfortable-to-use devices. Smartphones, gaming controllers, and wearables often utilize TPU and TPE materials, which significantly enhance impact resistance, ergonomics, and user experience.

Industrial Tools and Rugged Equipment

Industrial tools such as power drills, handheld scanners, and ruggedized electronics greatly benefit from overmolding. The protective, ergonomic layers enhance comfort, reduce user fatigue, and resist vibration, moisture, and harsh chemical environments, thereby improving durability and reliability.

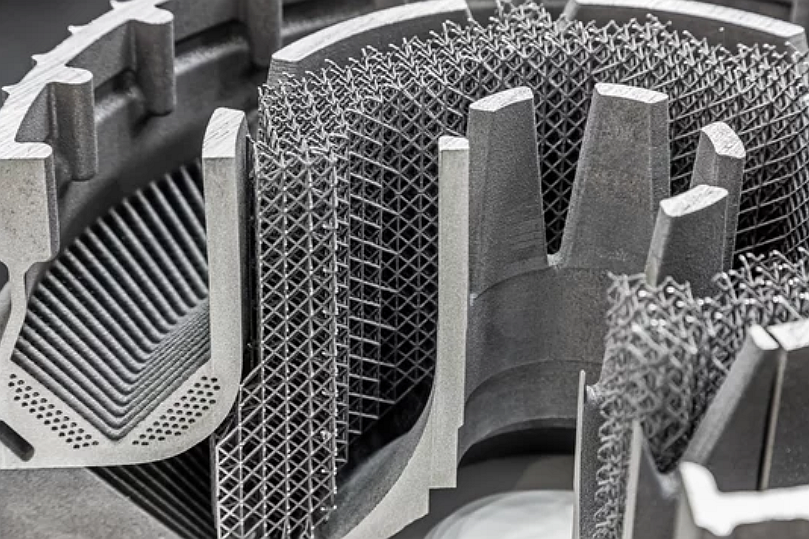

Designing for Success: Optimizing Overmolding Processes

Designing for Optimal Adhesion

Achieving strong bonds in overmolding involves carefully selecting compatible materials, meticulously engineering molds, and precisely controlling injection molding parameters. Properly optimized processes significantly enhance product durability and the reliability of adhesion.

Challenges and Common Pitfalls

Common pitfalls include the use of incompatible materials, poor bonding, adhesion defects, delamination, and increased production costs. Manufacturers may encounter inefficiencies and inconsistencies, which can negatively impact product quality and profitability.

Solutions and Best Practices

Thoroughly test material compatibility before manufacturing.

Precisely adjust injection parameters, including mold temperature, pressure, and flow rate.

Employ adhesion-promoting surface treatments or specialized mold designs to ensure consistent quality and robust adhesion in production.

Future Trends in Overmolding

Innovations in Filler Materials

Emerging filler technologies, including bio-based elastomers and nanocomposites, provide sustainable and performance-enhancing alternatives. These innovations enable manufacturers to meet environmental targets without compromising durability or reliability, which is particularly beneficial for the consumer electronics and healthcare sectors.

Technological Innovations

Advancements in automation, robotics, and real-time monitoring enhance overmolding precision and efficiency. These technologies allow greater consistency, quality control, and lower manufacturing costs, expanding opportunities for sophisticated, high-performance products.

Industry Impact

Technological advancements and material innovations in overmolding will continue to revolutionize product capabilities, durability, and aesthetics. Companies that proactively embrace these technologies will secure competitive advantages in performance-critical industries such as automotive, medical, and electronics manufacturing.

Conclusion

Overmolding represents a significant advancement in manufacturing, enabling the creation of superior products that seamlessly blend functionality, durability, and aesthetic sophistication. Manufacturers can achieve enhanced product performance, longevity, and consumer satisfaction by strategically selecting compatible materials, optimizing processes, and adopting cutting-edge technologies.

To excel in competitive markets, businesses must adopt advanced overmolding practices to meet the evolving expectations of consumers and industry standards. Embracing this sophisticated technique ensures continued innovation, market differentiation, and long-term success.