What materials are typically used in sheet metal stamping?

What Materials Are Typically Used in Sheet Metal Stamping?

1. Carbon Steel

Carbon steel is the most widely used material in sheet metal stamping due to its strength, affordability, and formability.

Low-carbon steel (e.g., AISI 1008, 1010): Easy to stamp and weld, ideal for automotive body panels, brackets, and enclosures.

High-strength low-alloy (HSLA) steel: Used in structural components and chassis parts where durability is required without excessive weight.

2. Stainless Steel

Known for its corrosion resistance and mechanical strength, stainless steel is common in medical devices, kitchen equipment, and telecommunication hardware.

Grades 304 and 316: Offer excellent corrosion resistance.

Grade 430: More affordable with good formability for indoor applications.

3. Aluminum Alloys

Aluminum is valued for its lightweight properties and good corrosion resistance.

Series 3000 and 5000 (e.g., 5052, 3003): Common in automotive, aerospace, and lighting housings.

Easily stamped but may require lubrication to prevent galling.

4. Copper and Brass

These materials are preferred where conductivity, appearance, or antimicrobial properties are important.

Copper (C110): Used in electrical connectors, terminals, and heat sinks.

Brass (C260, C360): Found in decorative trim, plumbing hardware, and fasteners.

5. Coated and Pre-Plated Metals

For parts requiring corrosion protection without secondary finishing:

Galvanized steel: Zinc-coated for corrosion resistance in HVAC, construction, and appliance applications.

Electro-galvanized and aluminized steel: Combine good appearance with paintability.

6. Specialty Alloys

High-performance applications may require:

Titanium: Lightweight and corrosion-resistant for aerospace or medical use.

Nickel-based alloys: For heat shields, exhaust systems, and high-temperature components.

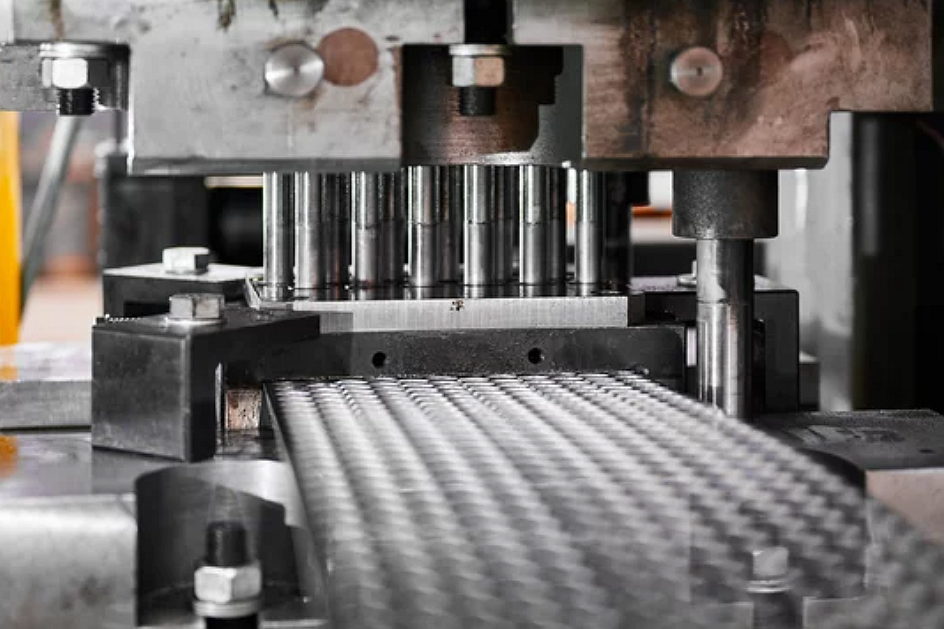

Manufacturing Services for Custom Stamped Metal Parts

Neway provides sheet metal stamping services with tooling for carbon steel, stainless steel, aluminum, and specialty alloys. With ±0.05 mm precision, 20+ years of expertise, and global delivery, we support industries from automotive to consumer electronics.