How precise can sheet metal stamping processes be?

How Precise Can Sheet Metal Stamping Processes Be?

Standard Tolerances in Sheet Metal Stamping

Modern sheet metal stamping processes—when performed with high-quality tooling and CNC-controlled presses—can achieve:

Dimensional tolerances: ±0.05 mm for blanking and forming

Flatness tolerances: within ±0.1 mm depending on material thickness

Hole-to-hole accuracy: ±0.05 mm with compound or progressive dies

These tolerances meet the demands of industries such as automotive, medical devices, electronics, and telecommunication.

Key Factors Influencing Stamping Precision

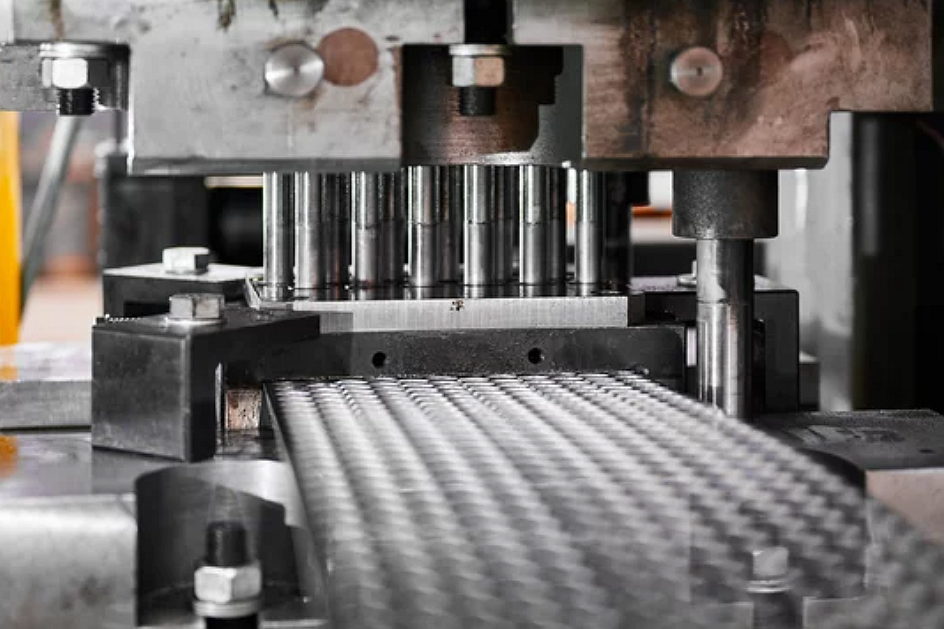

1. Tooling Quality and Die Design

Tight-tolerance dies with minimal clearance (typically 5–10% of material thickness) ensure accurate cuts and bends.

Progressive dies allow multi-stage operations with consistent alignment and reduced cumulative error.

2. Material Characteristics

Softer materials like aluminum and copper stamp cleanly and consistently.

Springback in high-strength steels or thick stainless steel may require compensation in die geometry.

3. Press Accuracy and Repeatability

High-end stamping presses offer repeatability within ±0.01–0.02 mm.

Servo-controlled presses improve precision by adjusting stroke depth and velocity based on real-time feedback.

4. Part Complexity and Bend Radii

Simple blanking operations maintain tighter tolerances than deep-drawn or multi-bend parts.

Internal features, embossing, and compound curves can introduce slight dimensional variation.

5. Lubrication and Material Feed Control

Proper lubrication reduces die wear and scoring, improving surface quality and dimensional repeatability.

CNC coil feeding systems minimize pitch error and misalignment during high-speed production.

Typical Stamping Precision by Operation Type

Operation Type | Typical Tolerance | Notes |

|---|---|---|

Blanking | ±0.05 mm | Best accuracy with tight-clearance dies |

Forming (bending) | ±0.1 mm | Influenced by springback and thickness |

Coining/Embossing | ±0.03–0.05 mm | High local accuracy in shallow features |

Piercing/Holes | ±0.05 mm | Can be improved with compound dies |

Manufacturing Services for High-Precision Stamped Parts

Neway delivers precision stamping services with ±0.05 mm tolerances using progressive and compound dies. With 20+ years of experience, in-house toolmaking, and CNC-controlled systems, we serve clients in automotive, energy, medical, and electronics industries.