What are the cost benefits of rapid molding compared to traditional methods?

What Are the Cost Benefits of Rapid Molding Compared to Traditional Methods?

Cost-Efficient Manufacturing Through Rapid Molding

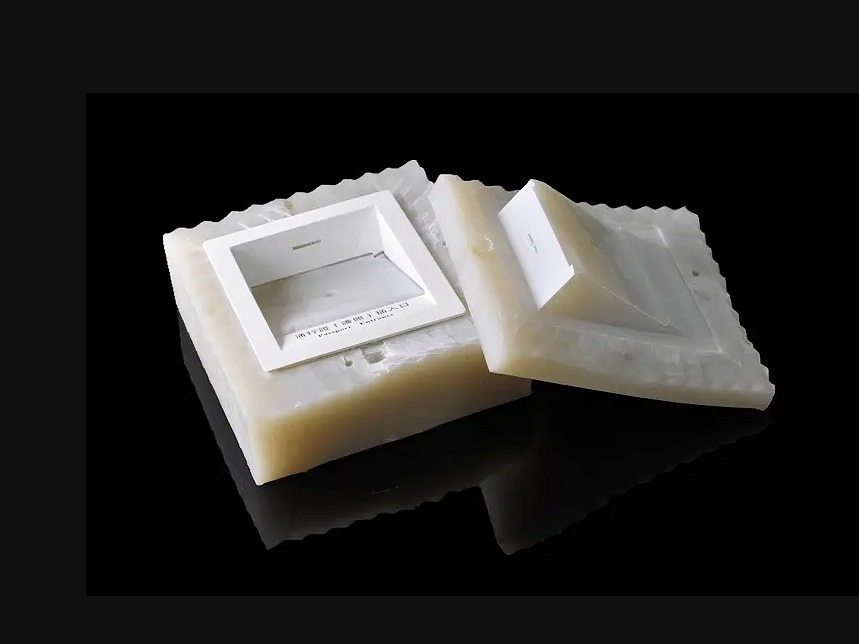

Rapid molding offers significant cost advantages over traditional injection molding when it comes to prototyping, bridge production, and low- to mid-volume manufacturing. By using aluminum or hybrid molds, manufacturers avoid the high upfront investment of hardened steel tooling while achieving production-grade part quality within a compressed timeline.

Key Cost Advantages of Rapid Molding

Lower Tooling Costs Traditional steel tooling can cost $20,000–$100,000+, depending on part complexity. In contrast, rapid aluminum tooling typically ranges from $1,500–$15,000.

Ideal for short runs and iterative design changes

Avoids sunk costs if product revisions are expected

Faster Time-to-Market = Lower Development Costs Rapid mold fabrication takes just 5–10 business days versus 4–8 weeks for steel tooling.

Reduces product development cycles

Shortens the window for return on investment

Low-Volume Efficiency For volumes under 10,000 parts, traditional molding may never amortize its tooling cost. Rapid molding delivers functional parts with lower total unit costs in small and mid-size batches.

Supports bridge production while scaling to mass manufacturing

Eliminates the need to overproduce just to justify tooling investment

Reduced Inventory and Waste With shorter lead times, manufacturers can produce parts on-demand and avoid overstocking.

Reduces warehousing costs

Increases cash flow efficiency

Cost-Effective Design Iteration Aluminum tools are easier to modify than hardened steel.

Engineers can implement design changes without scrapping an entire mold

Ideal for early-stage products and market testing

Example Cost Comparison

Method | Tooling Cost | Lead Time | Best Volume Range | Per-Part Cost (Low Volume) |

|---|---|---|---|---|

Rapid Molding | $1,500–$15,000 | 7–14 days | 50–10,000 units | Low–Medium |

Traditional Molding | $20,000–$100,000+ | 4–8 weeks | 50,000+ units | Very Low (at scale) |

Neway’s Value-Added Rapid Molding Services

Rapid Molding for cost-effective low-volume production

Injection Molding when scaling up is needed

Material Consultation to balance performance with cost

Prototyping support to minimize development risk

With ±0.05 mm accuracy, quick tooling turnaround, and global logistics, Neway enables cost-effective production at every stage of your product lifecycle.