What are common CNC machining methods used for precision parts?

What Are Common CNC Machining Methods Used for Precision Parts?

Precision CNC Machining: Core Techniques and Their Functions

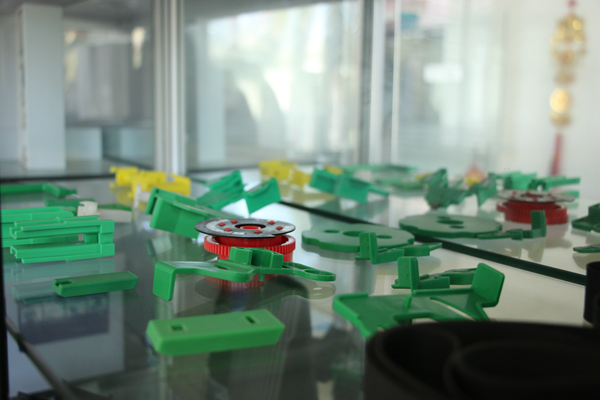

Precision CNC machining involves subtractive manufacturing processes that shape raw materials into complex, high-tolerance components. The most commonly used CNC machining methods offer various advantages in accuracy, surface finish, and scalability. These processes are often combined to meet strict tolerances (±0.01 mm or tighter) required in aerospace, medical, and semiconductor industries.

CNC Milling

CNC milling is the most versatile method, using rotating cutters to remove material along multiple axes. It supports 3-, 4-, and 5-axis operations, enabling the creation of parts with intricate contours, cavities, and tight geometries.

Typical Tolerance: ±0.01–0.05 mm

Applications: Housings, manifolds, engine components

Materials: Aluminum 6061/7075, stainless steel, titanium

CNC Turning

CNC turning uses a rotating workpiece and a stationary cutting tool to form cylindrical components. It's ideal for concentric shapes and offers exceptional dimensional control along the radial and axial axes.

Typical Tolerance: ±0.01–0.025 mm

Applications: Shafts, bushings, threaded parts

Materials: Tool steel, copper alloys, Inconel

5-Axis CNC Machining

5-axis machining allows simultaneous movement along X, Y, Z, and two rotary axes. This reduces setups, increases precision, and enables fabrication of complex 3D geometries.

Typical Tolerance: ±0.005–0.01 mm

Applications: Aerospace turbine components, surgical implants

Benefits: Eliminates alignment errors across setups, enables undercuts and compound angles

Wire EDM (Electrical Discharge Machining)

Wire EDM uses a high-voltage electrical spark to erode material from conductive workpieces. It’s ideal for producing sharp internal corners, narrow slots, and intricate profiles.

Typical Tolerance: ±0.002–0.005 mm

Applications: Mold inserts, gear dies, precision tooling

Materials: Hardened tool steels, titanium, superalloys

CNC Grinding

CNC surface and cylindrical grinding are used as finishing operations to achieve sub-micron flatness, roundness, and surface finishes down to Ra 0.2 µm.

Typical Tolerance: ±0.001–0.003 mm

Applications: Valve seats, bearing races, high-precision tools

Supporting Services to Optimize Precision

Neway’s capabilities include:

CNC Prototyping to validate part design before volume production

Multi-axis CNC Machining for geometrically complex precision parts

Material Selection Support for matching alloys with tolerance and stability requirements

With ±0.01 mm accuracy, automated inspection, and advanced toolpath control, Neway ensures high-repeatability production for all precision CNC parts.