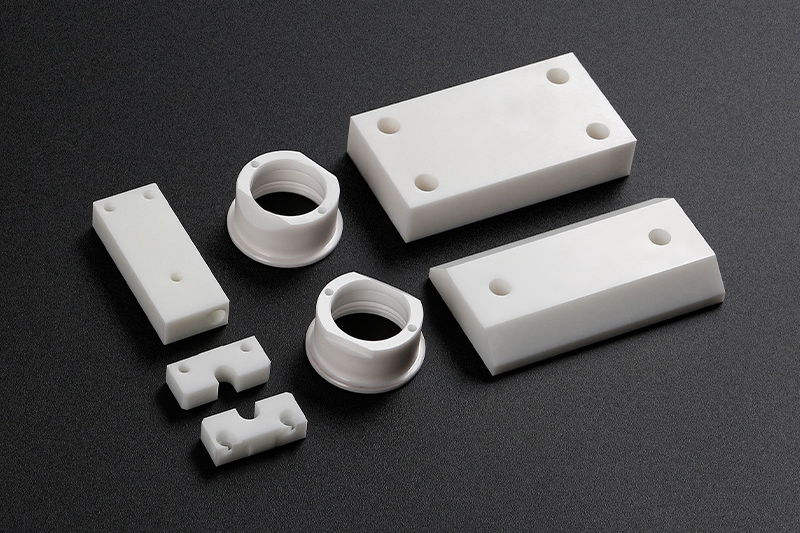

What Materials Are Used in Ceramic Injection Moulding?

Common Materials in CIM

In summary, CIM can mass-produce complex ceramic components from materials like alumina, zirconia, silicon carbide, and silicon nitride. Each material offers exceptional performance, like high hardness, strength, temperature capability, or corrosion resistance. CIM expands the design options and enables new applications using advanced structural and functional ceramics.

Ceramic injection molding (CIM) utilizes ceramic powder and binder materials as the molding compound. The composition and properties of the starting powders determine the characteristics of the final ceramic component. The most commonly used ceramic materials in CIM are:

Alumina (Al2O3)

Alumina, or aluminum oxide, is one of CIM's most versatile ceramic materials. It has excellent hardness, wear resistance, and temperature stability. Alumina powders with finely controlled particle size distribution and high purity levels are used. Some fundamental properties are:

- High hardness - Vickers hardness of 1600-1800 HV

- Compressive strength over 4000 MPa

- Flexural strength around 330 MPa

- Melting point of 2050°C

- Excellent corrosion and wear resistance

Due to its high strength and wear properties, alumina is ideal for automotive components like pistons, plungers, seal faces, and nozzle guides. It is also used for cutting tools, bearings, gears, and wear pads. Bioinert alumina is suitable for dental implants and orthopedic prosthetics.

Zirconia (ZrO2)

Zirconia offers very high fracture toughness and bending strength compared to other ceramics. Fine zirconia powders stabilized in the tetragonal phase are used in CIM. Key properties are:

- Vickers hardness over 1200 HV

- Flexural strength up to 1000 MPa

- Fracture toughness around 7-8 MPa√m

- Low thermal conductivity

- Corrosion resistant

Zirconia's strength and toughness make it worthwhile for high-stress components like valves, extrusion dies, knives, and mixer blades. It is also used for oxygen sensors, fuel cell membranes, and medical implants like hip joints.

Silicon Carbide (SiC)

Silicon carbide has excellent thermal shock and corrosion resistance. It has high hardness and strength at elevated temperatures. Reaction-bonded SiC powders are commonly used in CIM. Key properties are:

- Hardness similar to alumina

- Flexural strength around 550 MPa

- Thermal conductivity 90-120 W/mK

- Melting point 2700°C

- Retains strength at high temperatures

SiC components made by CIM are ideal for automotive applications like particulate filters, ceramic turbine blades, and exhaust gas heat exchangers. It also makes heating elements, ballistic armor plates, and aerospace components.

Silicon Nitride (Si3N4)

Silicon nitride offers high-temperature strength and creep resistance. Its properties include:

- Hardness of 1700 HV

- Strength over 650 MPa at 1000°C

- Fracture toughness around 6 MPa√m

- Melting point 1900°C

- Excellent thermal shock resistance

Si3N4 is suitable for automotive engine components, gas turbine parts, turbocharger rotors, missile nose tips, and spacecraft thruster nozzles. It is resistant to oxidation and thermal shock.

Alumina-Zirconia Composites

Composites of alumina and zirconia combine desirable properties like high hardness, strength, and toughness. Different ratios can be used depending on requirements. Some example properties include:

- Hardness of 1500 HV

- Strength around 1200 MPa

- Toughness 4-6 MPa√m

- Good wear resistance

- High-temperature stability

These composites are ideal cutting tools, extrusion dies, roller guides, and medical implants requiring a balance of strength, toughness, and bio-inertness. The properties can be tailored to specific needs.

Why Choose Neway for CIM Parts?

“We switched to Neway last year for all our injection molded parts and couldn’t be happier. The quality is outstanding, and their expertise in everything from plastics to ceramics injection is awe-inspiring. I highly recommend giving them a shot, especially with the 20% off promotion they’re running right now!” - John Smith, ACME Manufacturing