Inconel 718

Inconel 718 Similar grades

China: GH4169

Germany: W.Nr.2.4668

France: Nc19FeNb

Description

It has good comprehensive properties in the temperature range of -253 to 700°C. The yield strength below 650°C ranks first among deformed superalloys. It also has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, and good processing performance. , welding performance, and long-term structural stability. It can also manufacture various parts with complex shapes. It has been widely used in the above temperature range in the aerospace, nuclear energy, and petroleum industries.

Another feature of this alloy is that the alloy's structure is susceptible to the thermal processing process. By mastering the alloy's phase precipitation and dissolution rules and the relationship between the structure, process, and properties, reasonable and feasible process procedures can be formulated for different use requirements. Various parts are available to meet different strength levels and usage requirements.

Applications

Inconel 718 powders, with their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures, are highly sought after in several industries for various applications. These powders are particularly suited for additive manufacturing and powder metallurgy, enabling the production of complex components that benefit from the alloy's superior material properties. Here are some critical applications of Inconel 718 powders across different sectors:

Aerospace Industry

Turbine Engines: Inconel 718 is extensively used in manufacturing critical turbine engine components, such as discs, blades, and casings, which require materials that can endure high stress and temperatures exceeding 600°C.

Rocket Motors: The alloy's high-temperature strength and oxidation resistance make it ideal for rocket motors and space vehicle components that face severe thermal and mechanical stresses during launch and operation.

Airframe Parts: Its excellent fatigue resistance and durability under cyclical stress benefit airframe components, including fasteners and landing gear parts.

Power Generation

Gas Turbine Components: Inconel 718 powders are used to fabricate parts for gas turbines in power plants, such as rotors, seals, and casings, due to their ability to maintain structural integrity at high temperatures.

Nuclear Reactors: The alloy's good radiation resistance and strength at elevated temperatures support its use in manufacturing nuclear reactor components and fuel elements.

Automotive and Motorsport

High-Performance Engine Components: Inconel 718 is used in the automotive industry to manufacture high-performance engine parts, such as exhaust systems and turbocharger rotors, that require materials capable of withstanding extreme heat and corrosive conditions.

Oil & Gas Industry

Downhole Tools: The high strength and corrosion resistance of Inconel 718 make it suitable for downhole tools and completion equipment in oil and gas extraction, which encounter harsh corrosive environments and high pressures.

Valves and Piping: Components like valves, pump shafts, and piping systems exposed to sour gas and other corrosive media rely on Inconel 718 for its corrosion resistance and strength.

Medical Devices

Implants and Surgical Instruments: The biocompatibility and strength of Inconel 718 allow for its use in medical devices, including orthopedic implants and surgical instruments, where durability and resistance to body fluids are critical.

Manufacturing and Tooling

Molds and Dies: Inconel 718's resistance to wear and tear makes it suitable for molds and dies used in high-pressure and high-temperature conditions, such as plastic injection molding and metal die casting.

Composition and Properties

Inconel 718 powders are engineered from a nickel-chromium superalloy known for a unique blend of high strength, corrosion resistance, and ability to withstand extreme temperatures. This material composition and the resulting properties make Inconel 718 an ideal choice for challenging industrial applications, especially in aerospace, power generation, and oil & gas sectors.

Cr | Ni | C | Nb | P | S | Fe |

17.0-21.0 | 50.0-55.0 | 0.08 | 4.75-5.50 | ≤0.015 | Bal. | |

Powder Characteristics

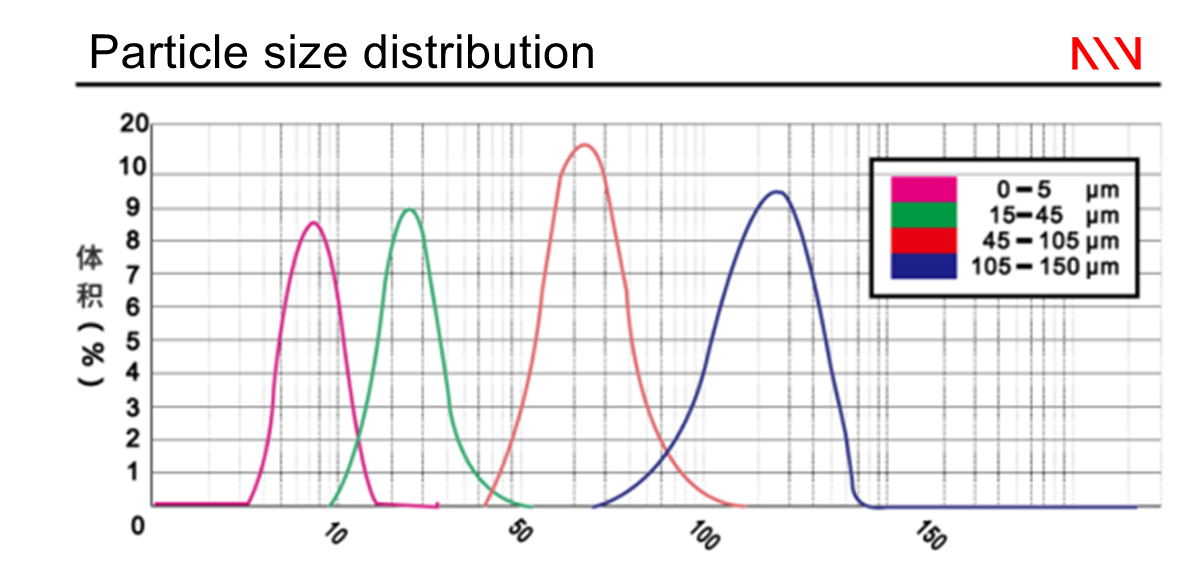

Particle Size Distribution: Tailored for specific additive manufacturing processes, typically ranging from 15 µm to 45 µm for selective laser melting (SLM) and electron beam melting (EBM).

Sphericity: High to ensure good flowability and packing density, crucial for consistent printing and sintering behavior.

Surface Morphology: Smooth surfaces with minimal satellites, optimizing the powder's flowability and packing properties.

Mechanical properties after the finished product | Powder state | ||||||||||||||||

Yield Strength | tensile strength | Elongation | size | 0- 15μm | 15-45μm | 45-75μm | 45- 150μm | ||||||||||

R p0.2/MPa | R m/MPa | δ5 /% | |||||||||||||||

Horizontal | ≥ 1030 | ≥ 1275 | ≥17 | form | spherical | spherical | spherical | spherical | |||||||||

Physical Properties of Inconel 718 Powders

Inconel 718 powders, tailored for additive manufacturing and powder metallurgy applications, exhibit specific physical properties that make them ideal for creating components that require high strength, excellent corrosion resistance, and durability at elevated temperatures. Below is a detailed overview of these properties:

Density: Approximately 8.2 g/cm³, inherent to the alloy's composition, provides an excellent strength-to-weight ratio for aerospace and automotive components.

Specific Surface Area: This varies based on particle size and morphology but is typically optimized to ensure efficient sintering and melting behavior in additive manufacturing processes.

Sphericity: High sphericity is crucial for Inconel 718 powders, promoting better flowability and packing density, essential for uniform layering and density in built parts.

Bulk Density: Ranges from 4.4 to 4.8 g/cm³, depending on the powder processing method and particle size distribution, affecting the powder's flowability and compaction.

Hall Flow Rate: The Hall flow rate of Inconel 718 powders is tailored to ensure excellent flowability, typically within the range that suits additive manufacturing equipment, ensuring consistent powder delivery and layering.

Melting Point: 1260-1335°C (2300-2435°F), which underlines the alloy's suitability for high-temperature applications, maintaining structural integrity under thermal stress.

Relative Density: Near-full density (>99.5%) is achievable in components manufactured from Inconel 718 powders, especially with optimal processing parameters in additive manufacturing, highlighting the material's capability for producing high-integrity parts.

Recommended Layer Thickness: A 20-50 μm thickness is typical for additive manufacturing applications, allowing for precise control over part geometry and microstructure.

Technical Standard: Inconel 718 powders for additive manufacturing are produced and tested according to stringent standards, such as ASTM B637 for aerospace applications, ensuring material quality and consistency.

Manufacturing Techniques

Manufacturing techniques for Inconel 718 powders leverage the unique properties of this nickel-based superalloy, enabling the production of components with exceptional strength, corrosion resistance, and high-temperature performance. The advanced manufacturing methods accommodate the complex geometries and precise specifications required in aerospace, automotive, and energy industries and offer significant advantages over traditional manufacturing processes.

Manufacturing Techniques

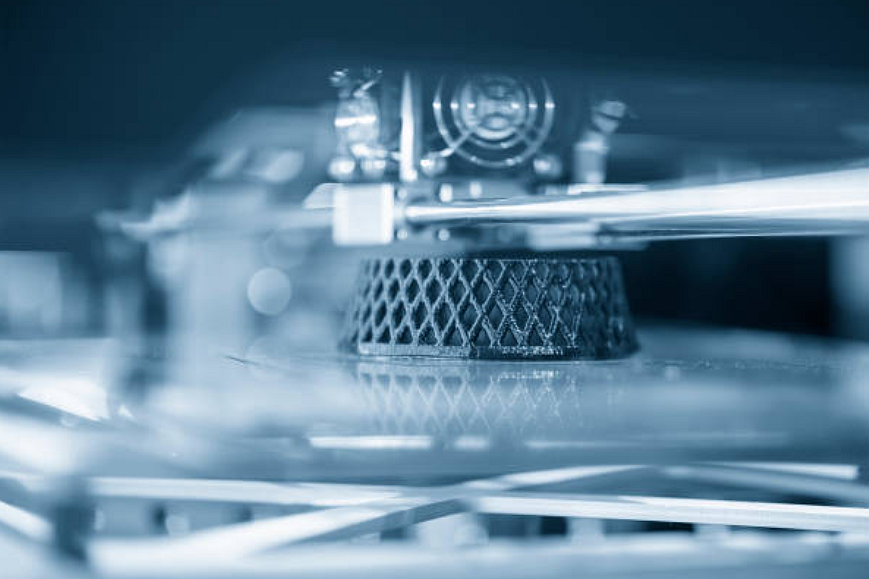

Selective Laser Melting (SLM): A form of additive manufacturing that fully melts and fuses Inconel 718 powder particles layer by layer using a high-power laser beam. This technique is ideal for creating complex, high-density components with intricate internal structures.

Electron Beam Melting (EBM): Similar to SLM, EBM uses an electron beam as the heat source to melt the metal powder. This process is conducted in a vacuum, reducing the risk of oxidation and producing parts with excellent mechanical properties.

Direct Metal Laser Sintering (DMLS): Another additive manufacturing method that sinters Inconel 718 powder without fully melting it, allowing for the fabrication of parts with complex geometries and minimal waste.

Hot Isostatic Pressing (HIP): Used to improve the properties of parts made from Inconel 718 powder by uniformly applying high pressure and temperature around a component to eliminate porosity and improve mechanical strength.

Powder Bed Fusion (PBF): Encompasses SLM and EBM techniques and produces components with reduced weight, high complexity, and minimal material waste.

Advantages in Production

Complex Geometry Fabrication: Additive manufacturing techniques allow for producing components with complex geometries that are difficult or impossible to achieve through traditional manufacturing methods, opening up new possibilities in design and functionality.

Reduced Material Waste: The layer-by-layer manufacturing process significantly reduces material waste, making it a more sustainable option than subtractive manufacturing techniques.

Enhanced Mechanical Properties: Parts produced from Inconel 718 powders can achieve superior mechanical properties, such as higher tensile strength and fatigue resistance, due to the refined microstructure achieved with these manufacturing processes.

Rapid Prototyping and Production: The ability to go directly from digital designs to physical parts reduces development and production times, allowing for faster iteration and customization of designs.

Cost-Effectiveness for Small Batches: Additive manufacturing is particularly cost-effective for small production runs and prototype development, as it does not require expensive molds or tooling.

Material Efficiency: The ability to use almost all of the powder material fed into the machine reduces the cost per part and contributes to more efficient use of high-value materials.

Manufacturing With Inconel 718 Powders