Incoloy 909

Incoloy 909 Similar grades

China: GH2909

United States: N19909

Description

Incoloy 909 is a nickel-iron-cobalt alloy known for its high strength and low thermal expansion coefficient. This nickel-based superalloy powder is specially formulated to maintain tight dimensional tolerances, which are essential for high-tech applications where precision is paramount. Incoloy 909's unique composition, which includes additions of titanium and aluminum, enhances its mechanical properties and stability across a wide temperature range, making it an ideal material for critical components in the aerospace, automotive, and energy industries.

The alloy combines high strength with thermal stability, preventing distortions in materials with higher expansion rates under thermal stress. It makes Incoloy 909 particularly useful in manufacturing parts that operate in environments subject to temperature fluctuations and require strict adherence to dimensional specifications.

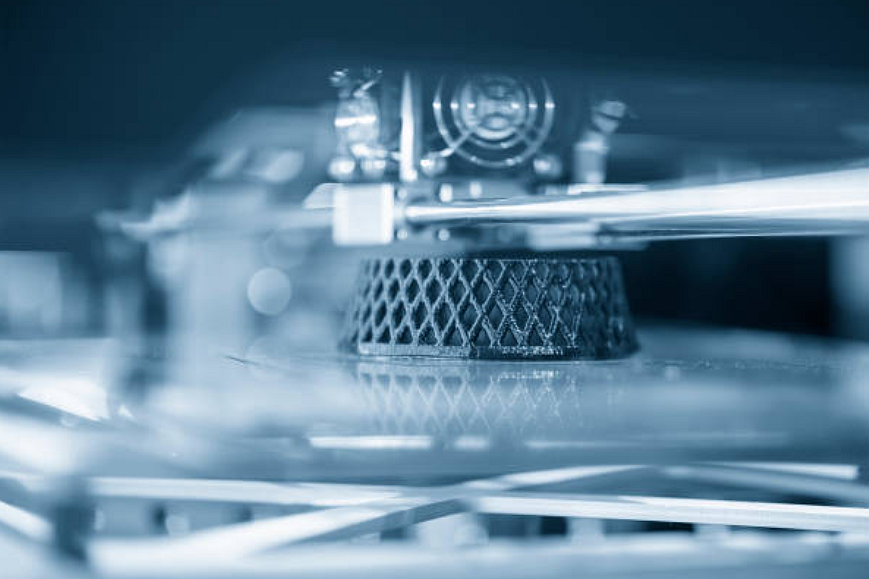

Incoloy 909 powder is tailored for various advanced manufacturing processes, including additive manufacturing (3D printing), which creates complex geometries that are difficult or impossible to achieve with traditional subtractive manufacturing methods. Its excellent weldability and fabricability further enhance its suitability for various industrial applications, offering manufacturers the flexibility to produce components with intricate designs and high-performance requirements.

Applications

Incoloy 909, a nickel-iron-cobalt superalloy, offers a unique blend of properties ideal for critical applications across various industries. Its specific attributes, including high strength, excellent thermal stability, and minimal thermal expansion, cater to precision parts manufacturing. Here, we delve into the specialized applications and manufacturing methods that leverage the exceptional qualities of Incoloy 909 alloy.

Aerospace Industry

Engine Components: Incoloy 909's resistance to thermal expansion and high-temperature strength make it perfect for aerospace engine parts. Components such as turbine disks, seals, and casings benefit from the alloy's stability under thermal stress, ensuring performance and reliability.

Structural Components: The aerospace sector also utilizes Incoloy 909 for manufacturing critical structural components. Its low expansion coefficient and high strength are crucial for parts that require minimal dimensional changes under varying temperatures.

Automotive Sector

High-Performance Engine Parts: Incoloy 909 is used in the automotive industry for components that demand tight tolerances and high strength at elevated temperatures. Examples include gears and fasteners that maintain their integrity and dimensions in challenging operational conditions.

Energy Sector

Nuclear and Power Generation Components: The energy sector values Incoloy 909 for its stability and strength in high-temperature environments. It's instrumental in nuclear reactors and other power generation systems where material properties must remain consistent under thermal cycling.

Composition and Properties

Incoloy 909, a nickel-iron-cobalt superalloy, distinguishes itself through a unique composition designed to offer exceptional strength and stability with minimal thermal expansion.

Inconel 909 Typical values(Weight%) | |||||||||||||

Cr | Mn | Ni | Ti | Co | C | P | Si | S | B | Mo | Cu | Al | Fe |

≤1.0 | ≤1.0 | 35.0-40.0 | 1.30-1.80 | 12.0-16.0 | ≤0.06 | ≤0.015 | ≤0.5 | ≤0.015 | ≤0.012 | ≤6.5 | ≤0.5 | ≤0.15 | Bal. |

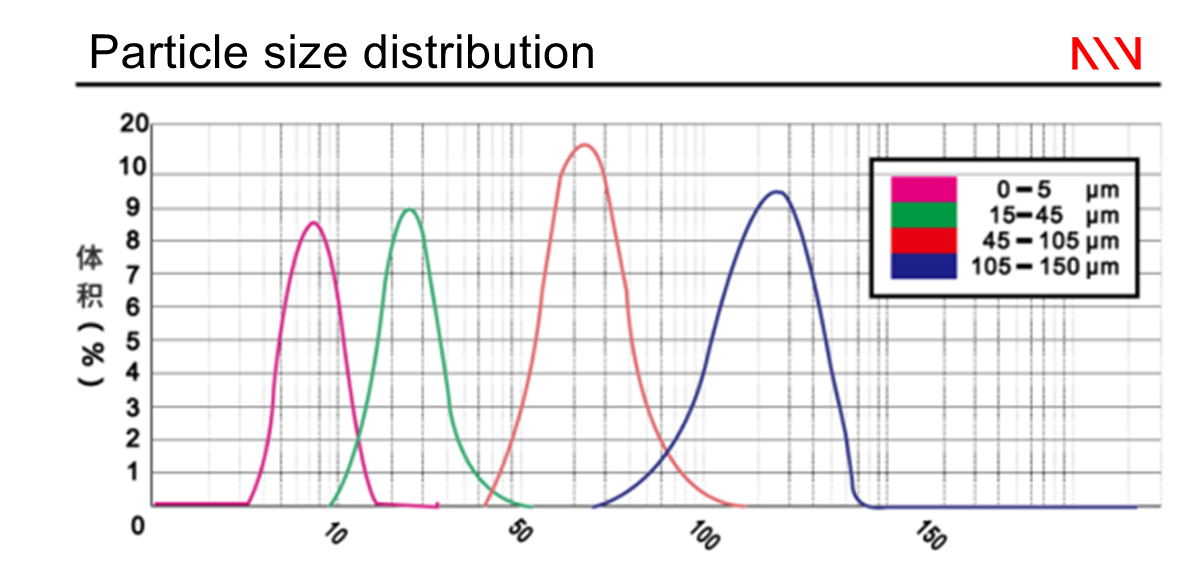

Powder Characteristics

The particle size distribution, morphology, and purity of Inconel 600 powders are critical for their performance in additive manufacturing and powder metallurgy. The powders are typically characterized by their spherical shape, promoting better flow and packing density, which is critical for achieving uniform and defect-free microstructures.

Mechanical properties after the finished product | Powder state | ||||||||||||||||

Yield Strength | tensile strength | Elongation | size | 0- 15μm | 15-45μm | 45-75μm | 45- 150μm | ||||||||||

R p0.2/MPa | R m/MPa | δ5 /% | |||||||||||||||

Horizontal | ≥ 1400 | ≥ 1700 | ≥15 | form | spherical | spherical | spherical | spherical | |||||||||

Physical Properties

Incoloy 909 stands out among superalloys, recognized for its unique blend of high strength, minimal thermal expansion, and excellent mechanical stability. This section highlights the key physical properties that make Incoloy 909 powders a preferred choice for sophisticated manufacturing processes, particularly in industries where precision and durability are paramount.

Density

Value: Approximately 8.19 g/cm³

Implication: The moderate density of Incoloy 909 contributes to its favorable strength-to-weight ratio, making it suitable for aerospace and automotive applications where reducing overall weight without compromising strength is critical.

Specific Surface Area

Value: Specific to particle size and morphology; optimized for enhanced powder-bed fusion in additive manufacturing.

Implication: A tailored specific surface area ensures efficient sintering and solidification processes, which is crucial for achieving high-density and defect-free components in additive manufacturing.

Sphericity

Value: High, with most particles exhibiting near-perfect spherical shapes.

Implication: High sphericity enhances flowability and packing density in powder-bed processes, leading to more uniform and consistent layers in additive manufacturing, which is vital for achieving optimal mechanical properties.

Bulk Density

Value: Ranges from 4.4 to 4.8 g/cm³, varying with processing and particle size distribution.

Implication: The bulk density impacts the powder layering process in additive manufacturing, influencing the deposition efficiency and layer uniformity, which are crucial for part quality.

Hall Flow Rate

Value: Optimized for additive manufacturing processes; indicative of excellent flowability.

Implication: A superior Hall flow rate signifies that Incoloy 909 powders can be quickly and consistently fed through additive manufacturing equipment, ensuring stable and continuous production cycles.

Melting Point

Value: 1190°C to 1210°C

Implication: The high melting point underscores the alloy's suitability for high-temperature applications, including those within the aerospace sector, where materials are subjected to extreme heat during operation.

Relative Density

Value: Achievable near-full density (>99.5%) in manufactured parts, depending on processing parameters.

Implication: Reaching near-full density indicates the material's capability to form solid, void-free components, which is crucial for structural integrity and performance.

Recommended Layer Thickness

Value: Typically 20-50 μm for additive manufacturing applications.

Implication: This range allows for precise control over part geometry and internal structures, enabling the production of components with complex shapes and high-detail resolution.

Technical Standard

Value: Incoloy 909 powders are produced and tested to meet rigorous industry standards, ensuring consistent quality and performance.

Implication: Adherence to technical standards guarantees that components made from Incoloy 909 powders will perform reliably under specified conditions, assuring durability and safety in critical applications.Manufacturing Techniques

Manufacturing Techniques

Incoloy 909, a superalloy distinguished by its exceptional strength, thermal stability, and low thermal expansion, is engineered for precision applications across various high-tech industries. This section explores the manufacturing techniques suitable for Incoloy 909 powders and highlights the production advantages of using this advanced material.

Manufacturing Techniques

Selective Laser Melting (SLM):

Process: SLM uses a high-power laser to fully melt and fuse metallic powders layer by layer, based on digital 3D models.

Suitability for Incoloy 909: Perfect for producing dense, complex geometries that leverage Incoloy 909's dimensional stability and strength at elevated temperatures.

Electron Beam Melting (EBM):

Process: Similar to SLM, but uses an electron beam as the energy source in a vacuum, reducing material oxidation and enhancing part purity.

Suitability for Incoloy 909: Ideal for components requiring exceptional mechanical properties and minimal internal stresses.

Process: DMLS sinters the powder without fully melting it, allowing for complex shapes with good material properties.

Suitability for Incoloy 909: Enables the fabrication of intricate designs where Incoloy 909's properties, such as low thermal expansion, are crucial.

Process: High pressure and high temperature improve material density and eliminate porosity in 3D-printed or traditionally manufactured parts.

Suitability for Incoloy 909: Enhances the mechanical properties of Incoloy 909 parts, making it suitable for critical applications in the aerospace and energy sectors.

Advantages in Production

Precision Component Fabrication: Incoloy 909 powders' adaptability to precision manufacturing methods like SLM and EBM enables the creation of components with tight tolerances and complex geometries, essential in aerospace and precision engineering.

Material Efficiency: Additive manufacturing processes significantly reduce waste by using material only where needed, making the production of Incoloy 909 components more sustainable and cost-effective.

Enhanced Performance: Components made from Incoloy 909 powders exhibit superior mechanical properties, including high strength and excellent thermal stability, which are critical for high-performance applications.

Design Flexibility: The ability to produce parts directly from digital models opens up new possibilities in design, allowing for optimizing component structures for performance and weight reduction.

Reduced Lead Times: Additive manufacturing techniques streamline the production process, from design to final part, reducing lead times and accelerating the development of new technologies.

Improved Material Properties: The HIP process can further enhance the properties of Incoloy 909 components, increasing density and eliminating internal defects, which is beneficial for the longevity and reliability of critical parts.