How cost-effective is 3D printing compared to traditional manufacturing methods?

How Cost-Effective Is 3D Printing Compared to Traditional Manufacturing Methods?

Evaluating the Economics of Additive Manufacturing

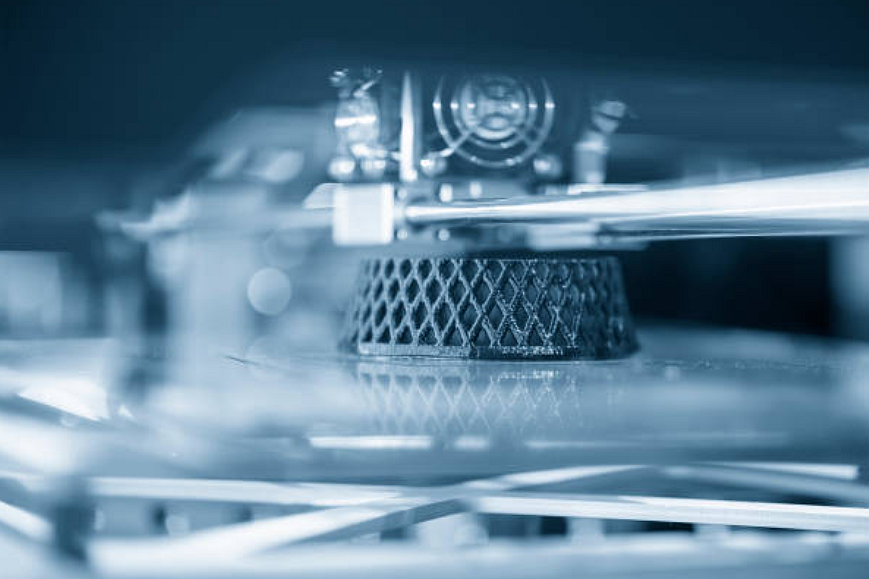

3D printing has become an economically viable solution for low-volume, complex, and custom part production. Unlike traditional manufacturing—which often requires expensive tooling and longer lead times—3D printing services offer cost-effective options for prototyping, bridge production, and even end-use parts with minimal setup costs and fast design iteration.

Cost Comparison by Production Volume and Complexity

Production Method | Setup Cost | Per-Part Cost (Low Volume) | Best Use Cases |

|---|---|---|---|

3D Printing (FDM/SLS/DMLS) | Low–None | Low ($5–$100) | Prototyping, custom parts, complex geometries |

CNC Machining | Medium | Medium–High ($20–$200) | Precision metal parts, moderate volumes |

Injection Molding | Very High | Very Low (<$1 at high volume) | Mass production of plastic parts (10k+ units) |

Die Casting | High | Low ($1–$5 at scale) | High-volume metal parts with moderate complexity |

For example, using Multi Jet Fusion (MJF) to produce 100 nylon brackets can cut costs by 45% and lead time by over 70% compared to injection molding when factoring out mold cost.

Key Cost Benefits of 3D Printing

No Tooling Costs 3D printing eliminates the need for molds, dies, or fixtures, making it ideal for custom and short-run production.

On-Demand Production Manufacturers avoid inventory and warehousing costs by producing parts only when needed.

Design Consolidation Complex assemblies can be redesigned as single, 3D-printed units, reducing BOM costs and assembly time.

Rapid Iteration Changes to CAD models can be implemented and printed in hours, drastically reducing R&D expenditure.

Material Efficiency Additive manufacturing minimizes waste, especially for high-value metals like Titanium and Inconel, which are expensive to machine.

When Traditional Methods Are More Cost-Effective

For mass production (10,000+ parts), processes like injection molding and die casting provide lower per-unit costs once tooling is amortized.

For tight tolerance machining, CNC machining may still offer superior precision and material range for functional prototypes.

Support Services for Cost Optimization

Neway enhances 3D printing cost-efficiency through:

Rapid Prototyping to reduce R&D cycles

Material Selection Support to balance price and performance

3D Printing for Superalloys to eliminate expensive machining steps

With ±0.01 mm accuracy, global delivery, and zero tooling cost, Neway enables cost-effective production across prototyping and low-to-medium volume manufacturing.