What is progressive stamping, and how does it benefit high-volume production?

Understanding Progressive Stamping

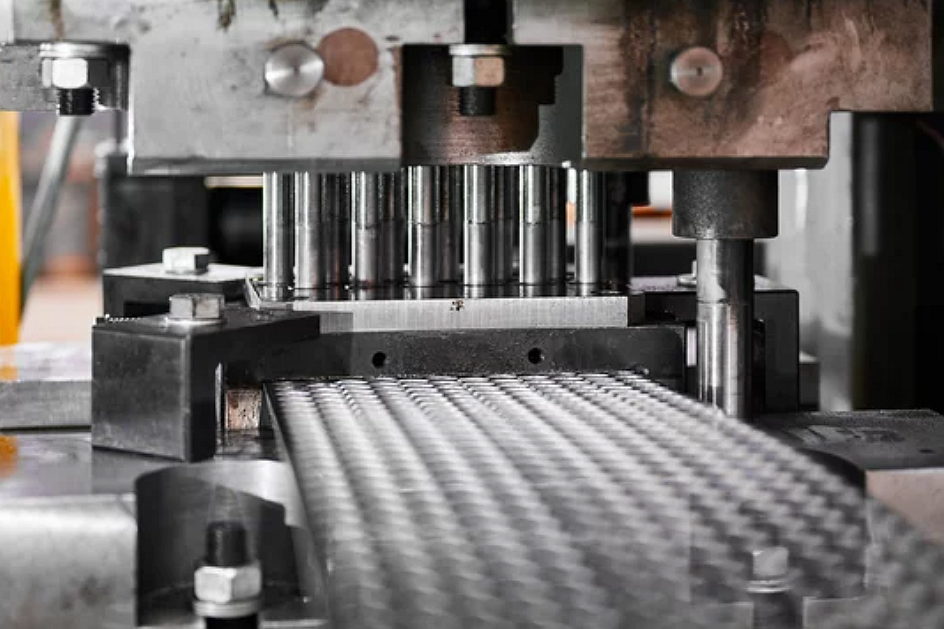

Progressive stamping is a high-efficiency sheet-metal manufacturing method where a metal strip is fed through a series of sequential die stations. Each station performs one operation—such as punching, bending, or coining—until the final station releases a fully formed part. The process is ideal for producing precise, repeatable components at scale and relies heavily on stable upstream cutting technologies, such as laser cutting, available through solutions like laser cutting, as well as forming capabilities, such as sheet metal fabrication.

In modern industrial applications, progressive stamping integrates seamlessly with other advanced forming methods such as metal bending and sheet metal stamping. For prototype validation before mass tooling, many OEMs also rely on prototyping to refine part geometry and ensure die accuracy.

Benefits for High-Volume Production

High Production Speed and Efficiency

Progressive stamping is designed for continuous production. Once the die is set, a single stroke of the press advances the strip through all stations simultaneously. This enables extremely high production rates, making the method ideal for industries that require large-scale component output, such as automotive, telecommunications, and consumer electronics.

Consistent Precision and Tight Tolerances

Because multiple operations are integrated into one die set, dimensional variation is minimized. Material-specific characteristics define achievable tolerances, and manufacturers often choose alloys such as stainless steel, carbon steel, copper alloy, alumina-zirconia, or ABS depending on strength, conductivity, or cost targets.

Cost Advantages in Mass Production

Progressive stamping significantly reduces unit cost at high volume because all forming actions are consolidated into one continuous process. Tooling is a major upfront investment, but once completed, the per-part cost decreases rapidly. This scalability is one reason many manufacturers combine progressive stamping with casting options like zinc die casting or aluminum die casting when multiple components must be produced economically at high volumes.

High Material Utilization and Reduced Waste

Progressive dies are engineered to optimize strip layout, thereby reducing raw material waste. Combined with modern finishing technologies such as sandblasting or electropolishing, stamped components achieve excellent surface consistency.

Versatility in Component Complexity

Progressive stamping can integrate complex operations such as embossing, threading, or multi-stage bending. When product design requires hybrid manufacturing, the process transitions smoothly into operations such as precision casting or injection molding for assemblies containing mixed-material components.