Does Neway offer functional testing for prototype parts?

Yes. Neway not only manufactures prototypes but also supports functional testing to verify whether parts behave as intended under real or simulated operating conditions. By combining dedicated prototyping services with application-specific test protocols, we help customers reduce design risk before committing to full-scale production.

Functional Testing Capabilities for Different Prototype Types

For high-precision mechanical components produced via CNC machining prototyping, Neway can perform fit and tolerance verification, torque and load evaluations, motion and wear assessments, and assembly interaction checks. This is especially important for mechanisms in power tools or locking systems, where repeatable actuation and long-term durability are critical.

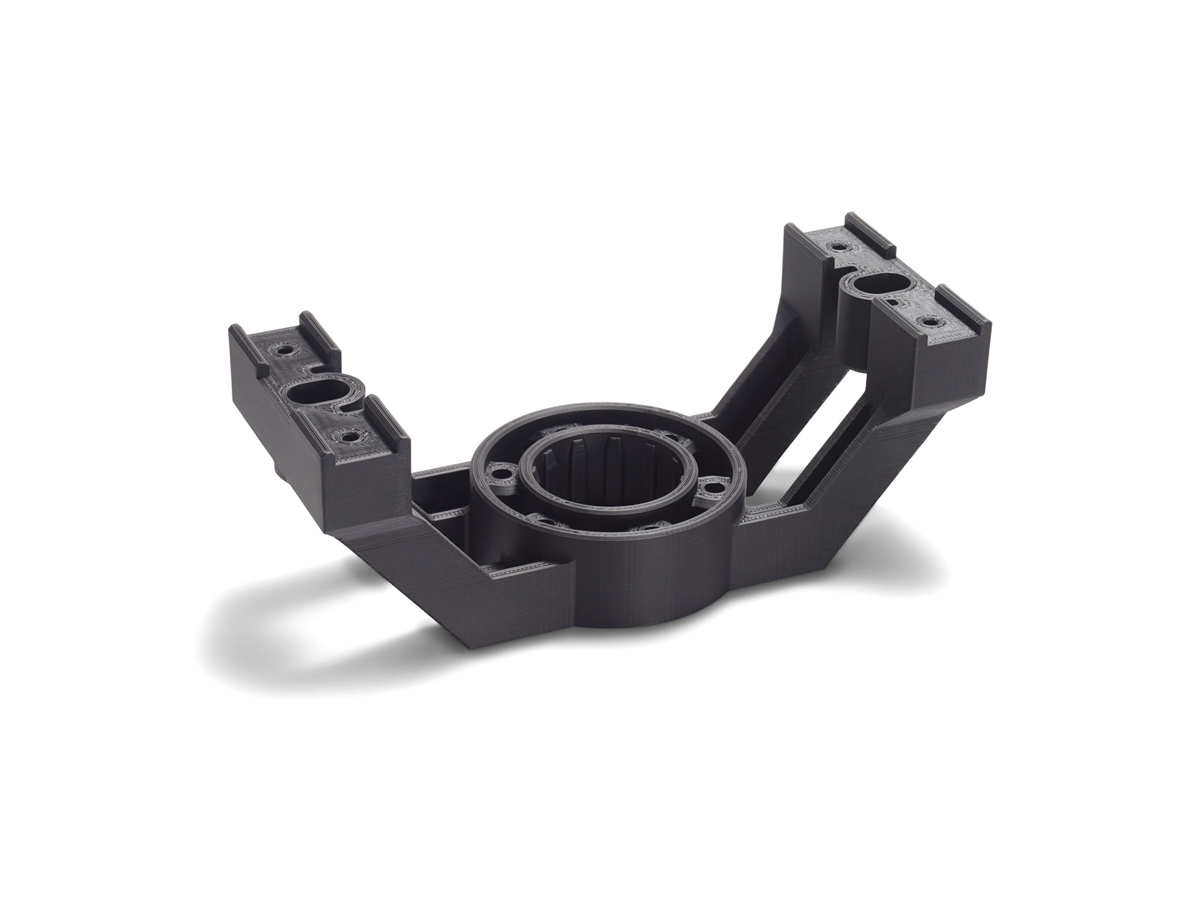

For complex geometries created with 3D printing prototyping, we focus on functional evaluations such as snap-fit performance, sealing behavior in housings, airflow or fluid path integrity, and ergonomics in consumer electronics enclosures. These tests validate design concepts quickly before tooling investment.

When parts are built through rapid molding prototyping, Neway can replicate end-use conditions more closely, including cyclic loading, impact, and thermal cycling—especially relevant for automotive and aerospace applications where reliability is paramount.

Using Production-Like Materials and Processes for Realistic Results

To ensure functional testing results truly reflect production performance, Neway selects materials that match or closely approximate the final specification. For plastic prototypes, engineering grades such as ABS, polycarbonate, or high-performance PEEK allow validation of stiffness, impact resistance, and dimensional stability under load.

For metal parts that must withstand high stress or temperature, Neway can prototype using alloys like AlSi10Mg, Inconel 718, or production-equivalent cast aluminum through precision casting or aluminum die casting. This ensures thermal fatigue, creep, or vibration testing reflects real-world behavior.

Where ultra-hard or wear-resistant components are required, such as valves or medical instruments, ceramics like zirconia can be produced via ceramic injection molding, enabling functional tests on fracture toughness, sliding wear, and sealing performance.

Simulating Real Service Conditions With Surface Treatments

Many functional tests depend on the final surface condition. Neway can apply surface treatments during the prototype phase to simulate friction, corrosion resistance, or thermal protection. For metal housings or structural parts, anodizing and powder coating help evaluate scratch resistance, color stability, and corrosion performance in outdoor or industrial environments.

For high-heat components, especially in energy or aerospace applications, advanced coatings like thermal coating or thermal barrier coating can be integrated into the prototype stage to assess insulation efficiency and coating integrity under cyclic thermal loading.

How Neway Collaborates on Functional Testing Projects

Clarify application requirements, including loads, environment, lifetime, and regulatory constraints (for example, in medical devices or telecommunication hardware).

Select the most suitable prototype process—CNC, 3D printing, or molding—based on accuracy, material, and testing requirements.

Define measurable functional test criteria, such as torque, sealing pressure, insertion/extraction force, or cycle count to failure.

Iterate on the design based on test data, refining the geometry, material, or surface treatment to converge on a robust, production-ready solution.

Prepare a smooth transition from prototype validation to mass production using Neway’s custom parts manufacturing service.