Which industries benefit most from green sand casting practices?

Automotive Manufacturing

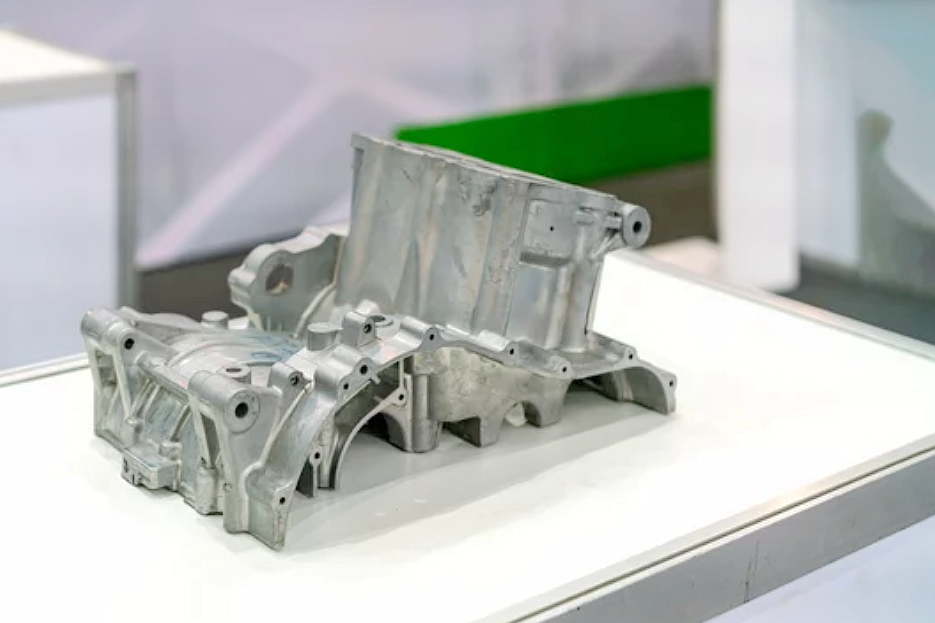

The automotive industry is one of the largest adopters of green sand casting, driven by its demand for high-volume, cost-effective metal components. Components such as engine blocks, brake housings, and transmission covers are efficiently produced through green sand molds. The ability to reuse molding sand and minimize scrap metal not only lowers environmental impact but also supports automotive OEMs in meeting carbon reduction and sustainability targets.

Energy and Power Generation

The energy sector benefits from green sand casting’s flexibility in handling various alloys, including cast iron, carbon steel, and copper alloys. These materials are essential for turbines, pump housings, and heat exchangers. By utilizing recyclable sand systems and efficient melting processes, foundries reduce both energy consumption and emissions in the production of large, durable components for power generation and renewable energy equipment.

Heavy Machinery and Industrial Equipment

Manufacturers of heavy-duty machinery rely on green sand casting for structural components that demand excellent strength and vibration resistance. The process is ideal for producing large castings with complex geometries at moderate tooling costs. Coupled with heat treatment and surface finishing methods such as sandblasting and black oxide coating, it enhances part longevity in demanding environments.

Aerospace Components

For the aerospace industry, green sand casting is utilized in prototype and low-volume production of structural parts. Its adaptability allows engineers to test complex designs using materials like aluminum alloys and magnesium alloys. As sustainability becomes central in aerospace manufacturing, using recyclable sands and reduced-emission binders aligns with industry commitments to greener production processes.

Agricultural and Construction Equipment

Producers of agricultural machinery and construction tools benefit from the durability and scalability of green sand cast parts. Axle housings, gearbox covers, and hydraulic fittings are commonly cast using iron and steel. The reuse of molding sand and minimized energy consumption contribute to sustainable manufacturing while maintaining high mechanical performance in rugged applications.

Marine and Pump Industry

The marine and fluid handling industries utilize green sand casting to manufacture corrosion-resistant parts from bronze and stainless steel alloys. The process ensures dimensional accuracy while enabling eco-friendly surface treatments, such as electropolishing and powder coating, which reduce environmental impact in saltwater and chemical applications.

Consumer and Lighting Hardware

The lighting solution and consumer product sectors also benefit from the versatility of green sand casting. Manufacturers can produce complex housings, decorative fixtures, and custom components with minimal tooling waste. The recyclability of molding sand aligns with the modern consumer electronics and architectural lighting industries, which prioritize sustainable sourcing and low-waste production.

E-Mobility and Sustainable Transport

The e-mobility industry integrates green sand casting to create lightweight, thermally efficient components for electric vehicle platforms. Casting alloys like A356 aluminum help reduce vehicle mass, improving range and performance while adhering to eco-design principles that minimize emissions across the manufacturing lifecycle.