Which industries benefit most from the material versatility of sand casting?

Introduction

Sand casting is highly valued across diverse manufacturing sectors due to its ability to accommodate a wide range of metals—from lightweight aluminum to high-strength steels and corrosion-resistant copper alloys. Its adaptability allows engineers to balance mechanical performance, cost, and design flexibility. By combining the right materials with precise surface finishing and heat treatment processes, sand-cast parts can meet the demanding requirements of multiple industries.

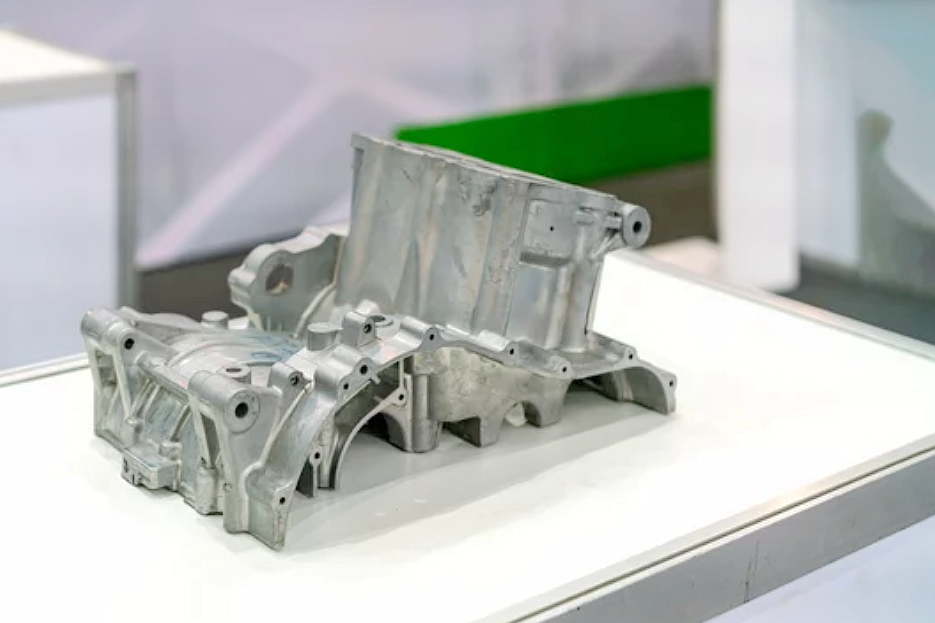

Automotive Industry

The automotive sector leverages sand casting for engine blocks, manifolds, suspension brackets, and transmission housings. Alloys such as cast aluminum and cast iron offer an optimal combination of strength, weight reduction, and vibration damping. This versatility enables automakers to improve fuel efficiency while maintaining structural integrity under dynamic loads.

Aerospace Industry

In the aerospace industry, sand casting enables the production of complex geometries using nickel-based alloys, magnesium alloys, and high-strength steels. These materials withstand extreme temperatures and pressures found in turbines and structural components. The process enables the rapid prototyping and production of lightweight yet durable parts, which are critical for flight performance and safety.

Energy and Power Generation

The energy sector benefits significantly from sand casting’s ability to handle heat-resistant materials, such as carbon steel and stainless steel. These metals are ideal for valves, pump housings, and turbine components exposed to high thermal and pressure loads. Additional processes, such as nitriding and thermal coating, further enhance wear and fatigue resistance, thereby extending the operational lifespan.

Consumer Electronics and Telecommunication

In consumer electronics and telecommunication, copper-based and aluminum alloys are favored for their thermal and electrical conductivity. Sand-cast frames, connectors, and heat sinks combine strength with efficient heat dissipation. Finishing techniques, such as electropolishing and painting, provide aesthetic refinement and surface protection, which are essential for modern electronic housings.

Industrial Machinery and Power Tools

For industrial machinery and power tools, sand casting enables the production of large, robust components with dimensional stability and cost efficiency. Materials like ductile iron and zinc alloys offer excellent wear resistance and damping capacity—ideal for high-torque and repetitive-load environments.

Medical and Specialized Equipment

The medical device industry also benefits from sand casting’s ability to handle cast stainless steel and cast titanium. These biocompatible metals are essential for surgical tools, diagnostic housings, and structural components requiring sterilization and corrosion resistance.

Conclusion

The material versatility of sand casting makes it indispensable across various sectors that require a balance of performance, durability, and cost control. By tailoring alloys and finishes—from lightweight aluminum to corrosion-resistant stainless steel—manufacturers can achieve customized solutions that meet the unique operational demands of every industry.