What are the main differences between 3D printing and CNC machining for automotive prototypes?

How the Two Processes Differ in Automotive Development

3D printing and CNC machining are the two most common technologies for automotive prototyping, but they serve different engineering needs. At Neway, both are used strategically depending on geometry, mechanical load, and validation requirements. When rapid form-fit-function parts are required, 3D printing prototyping provides unmatched design freedom and rapid iteration cycles. For high-precision assemblies or performance validation, CNC machining prototyping delivers tighter tolerances, superior surface quality, and production-representative mechanical behavior.

Comparison of Manufacturing Characteristics

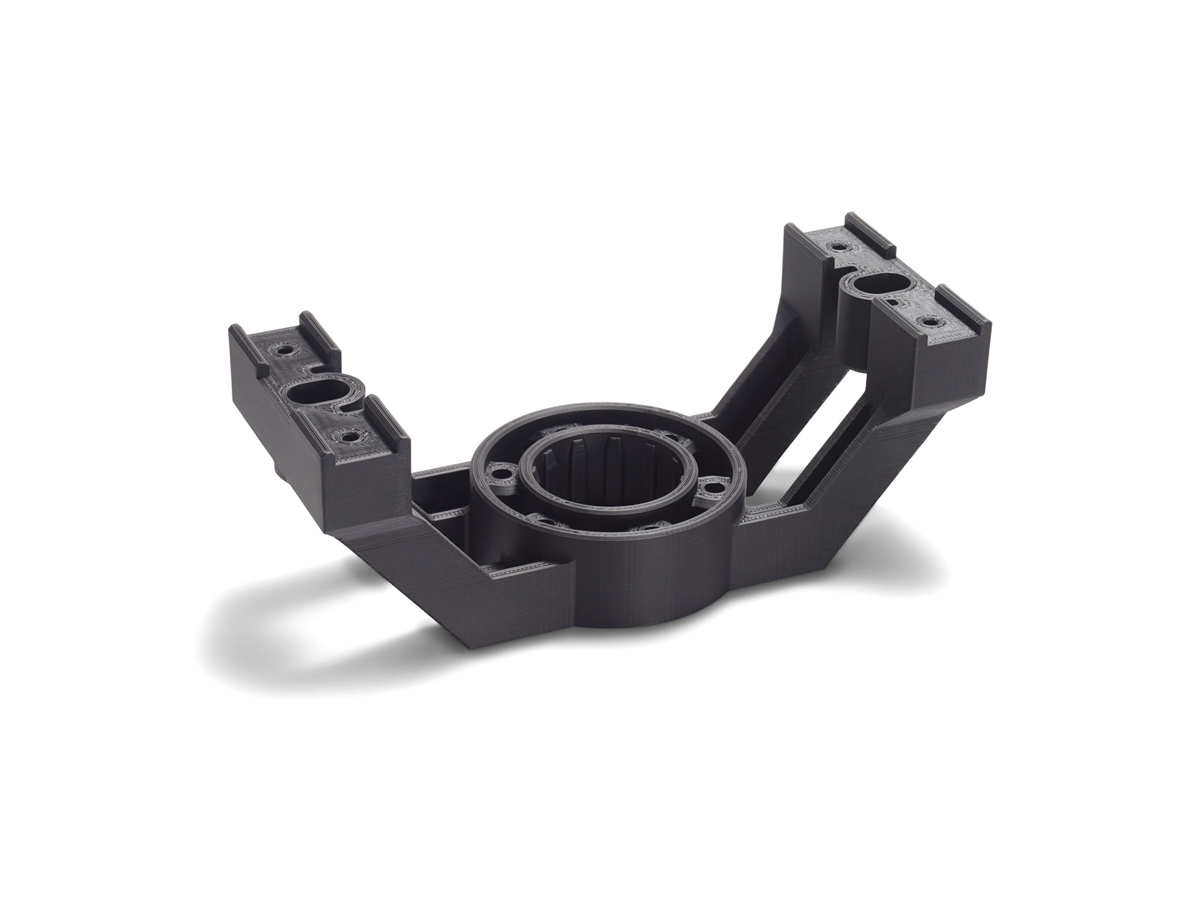

3D printing builds parts layer by layer, making it ideal for lightweight structures, internal channels, and complex housings. This approach significantly reduces lead time for early design trials and simplifies changes. Process versatility is further enhanced by material options, including 6000 series aluminum, AlSi10Mg, and reinforced engineering plastics. In contrast, CNC machining removes material from a solid block using high-precision cutting tools. Complex metal prototypes—especially brackets, mounts, and engine-bay components—often rely on machined materials, such as carbon steel or heat-resistant cast stainless steel, for mechanical integrity during functional tests.

Material Performance and Strength Differences

Additively manufactured parts support early structural evaluation but may not fully replicate the strength of production-grade components. Metals such as Inconel 718 or Haynes 188 enable high-temperature prototype testing, while engineering plastics are used for interior and under-dash components. CNC machining, however, provides unmatched consistency and true production-grade performance because machining directly uses solid metal or molded blanks. When a part requires representative thermal, fatigue, or vibration behavior, machined prototypes outperform printed components.

Surface Finish and Post-Processing Needs

Printed parts typically require smoothing or coating to reach assembly-ready finish levels. Many automotive prototypes undergo a refined painting process or deburring before testing. Machined parts can be delivered with tight tolerances and an as-machined finish, making them ready for installation on a rig or vehicle. For thermal components, additional protection may be applied using thermal coating to simulate real operating environments.

Best Applications in the Automotive Industry

In the automotive sector, 3D printing is ideal for prototypes requiring rapid concept validation, airflow models, ergonomic checks, and lightweight structural studies. CNC machining is preferred for drivetrain components, chassis interfaces, and e-mobility assemblies that require meeting production-level tolerances and strength. For early-stage functional testing, both technologies may be combined—printed blanks followed by machining on critical surfaces—to deliver speed without sacrificing accuracy. In the areas of electrification and thermal management within e-mobility and energy, hybrid approaches are becoming increasingly essential for fast-moving development cycles.