How to lightweight battery enclosures while keeping strength and safety?

Lightweight battery enclosures must strike a balance between structural integrity, crashworthiness, thermal management, and manufacturability. At Neway, we combine material engineering, structural optimization, and process selection to reduce weight while still meeting demanding safety requirements for applications such as e-mobility systems, automotive platforms, and energy storage solutions.

Selecting lightweight and robust material systems

Material choice is the foundation of a lightweight enclosure. For metal designs, aluminum alloys are often preferred because they offer a high strength-to-weight ratio and good corrosion resistance. Neway can deliver structural housings via aluminum die casting using optimized alloys such as A380 aluminum or through cast aluminum components when more complex geometries or thicker sections are required.

For even more aggressive mass reduction, magnesium alloy structures can be considered, especially in areas where stiffness-to-weight is more critical than ultimate strength. In sheet-metal architectures, sheet metal fabrication with high-strength aluminum or steel grades enables the creation of thin yet stiff enclosures featuring folded and ribbed designs.

Hybrid metal–plastic designs are another effective strategy. Structural shells may be metal, while covers or secondary modules are made from engineering plastics such as PC-PBT blends for impact resistance or PEEK for high-temperature and chemical resistance. These are produced through injection molding, enabling thin walls, integrated clips, and sealing features.

Optimizing geometry and manufacturing process

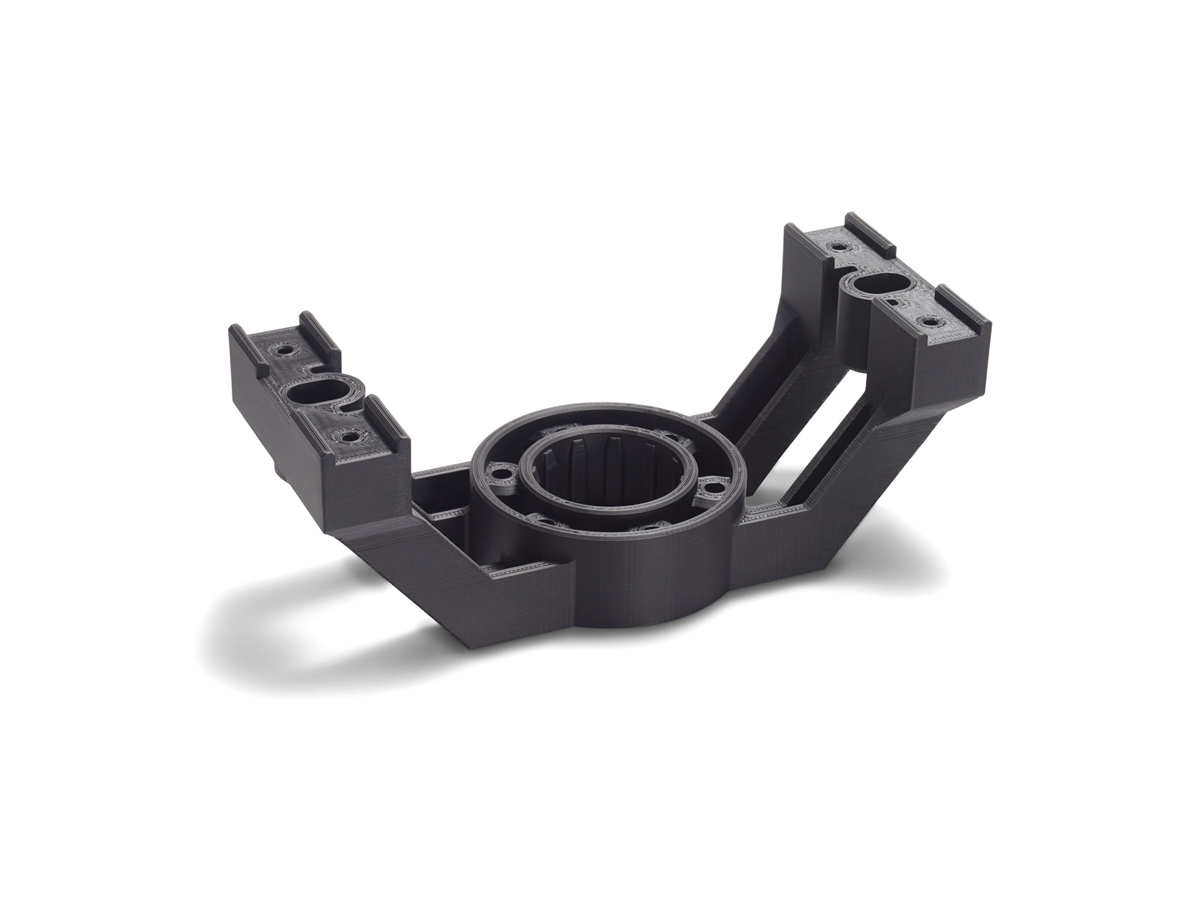

Weight reduction does not come only from material substitution; geometry optimization is equally critical. Using ribs, beads, and local stiffeners allows walls to be thinned while maintaining stiffness. Processes like 3D printing prototyping and CNC machining prototyping enable quick evaluation of alternative rib patterns, mounting schemes, and sealing concepts before committing to final tooling.

Once the design is validated, Neway can replicate production conditions with rapid molding prototyping, ensuring that gating, flow, and shrinkage effects are understood for injection-molded or overmolded battery covers. For metal designs with larger footprints, laser cutting, metal bending, and sheet metal stamping are combined to form lightweight yet crash-capable enclosure shells.

Managing thermal behavior and safety

Battery safety is closely tied to thermal management and containment. Lightweight enclosures must still provide adequate heat dissipation, fire barriers, and gas venting. Metal housings can be enhanced with anodizing to improve corrosion resistance without significant weight gain, and powder coating or painting to provide electrical insulation and environmental protection.

For high-temperature zones or modules near exhaust components, thermal protection layers are essential. Neway can apply thermal coating systems or thermal barrier coatings to selected surfaces, reducing heat ingress and enabling the use of thinner wall sections without compromising safety margins.

Validation and industrialization

Before mass production, Neway conducts structural and functional validation using prototypes built under realistic conditions. Through prototyping services, we can verify sealing integrity under pressure, mechanical performance under vibration and shock, and durability under thermal cycling. The findings are fed back into DFM optimization to refine dimensions, fasteners, and joinery methods.

Finally, Neway’s custom parts manufacturing service scales the validated design into stable serial production, maintaining tight process control to ensure that lightweight battery enclosures consistently meet strength, safety, and regulatory requirements.